More than 200 battery factories are expected to be built globally in the next ten years, with a significant number located in Europe, necessitating billions in production technology. A study by Porsche Consulting and VDMA highlights this as a historic growth chance for German and European machinery and plant manufacturers, advising on how to capitalize on this opportunity.

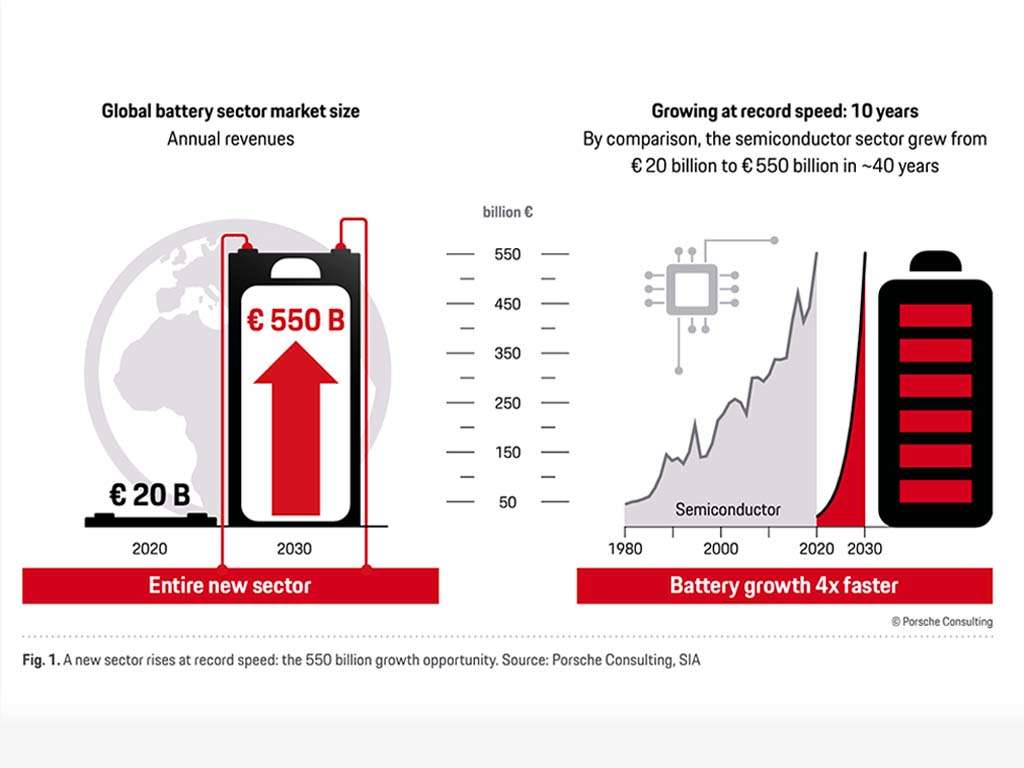

The future of mobility heavily relies on electric drives, primarily for road transport, with the majority of green electricity to be stored in batteries, predominantly using lithium-ion technology. The global market for such power storage is expected to grow from approximately €20 billion to €550 billion annually by 2030, marking a rapid expansion compared to the semiconductor industry’s growth over the past 40 years.

Currently, about 200 battery factories are under construction or planned worldwide, with production technology mainly sourced from Asia. Chinese manufacturers, offering complete solutions, set the standard, leaving only 8% of high-tech equipment coming from Europe. The study suggests that for Europe to influence technological development and establish a secondary hub for battery technology, it would need to secure around 20% of the market share, a significant leap from the current 8%.

Related articles:

- LFP Specialist IBU-Tec Advances Sodium-Ion Battery Technology

- Funding for ACC’s Gigafactories Across Europe Totals €4.4 Billion

- Europe’s Largest Green Loan: Northvolt Secures $5 Billion for Battery Production Expansion

It emphasizes the importance of European machinery builders working together to offer integrated factory solutions to compete with Asian counterparts, highlighting the technological parity but also the need for collaboration to reduce interface risks and financial uncertainties in setting up factories.

The potential for growth is substantial, with machinery builders needing to achieve growth rates of 33% annually just to maintain an 8% market share during the sector’s rapid expansion. To reach a 20% market share, they would have to grow faster than the market, potentially increasing revenues by 50% per year, which is both necessary and feasible.

The study projects a market volume of €300 billion by 2030 for machinery and plant manufacturers in the battery sector alone, indicating that success in this area could permanently secure Europe’s access to crucial battery technology and create many jobs. The German and European mechanical engineering sectors are actively addressing the challenge, with partnerships and collaboration being key to innovation and responding to the high demand for innovative battery production solutions, as demonstrated by companies like Manz AG through strategic investments and joint ventures.

The research study emphasizes the importance of reacting to consumer demands for turn-key providers during the industry ramp-up period, as well as new challenges and opportunities for experienced machinery and plant makers.

Source: Porsche Newsroom, Porsche-Consulting Report (Study as PDF)