The worldwide demand for energy storage systems is increasing. However, the use of critical raw materials in lithium-ion batteries limits their ability to meet this demand. As a result, there is a search for alternative battery technologies. One such promising project is the ‘four-volt sodium-ion battery’ (4NiB), which aims to make progress in this area.

The Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) in Germany is collaborating with three renowned partners to develop sodium-ion batteries that are powerful, cost-efficient, and environmentally friendly. Biological waste will also be used in the project. The batteries will be customized for use in electric vehicles in urban traffic and stationary battery storage systems. A total of 1.35 million euros over three years will be provided for the project by the Federal Ministry of Education and Research (BMBF).

In addition to the ZSW in Ulm, the 4NiB consortium’s project partners include well-known institutions such as the Helmholtz Institute Ulm-Karlsruhe with the Institute of Technology (HIU-KIT) and the Forschungszentrum Jülich GmbH with the Institute of Energy and Climate Research. Another collaborator is the Albert Ludwigs University of Freiburg’s Freiburg Materials Research Center (FMF).

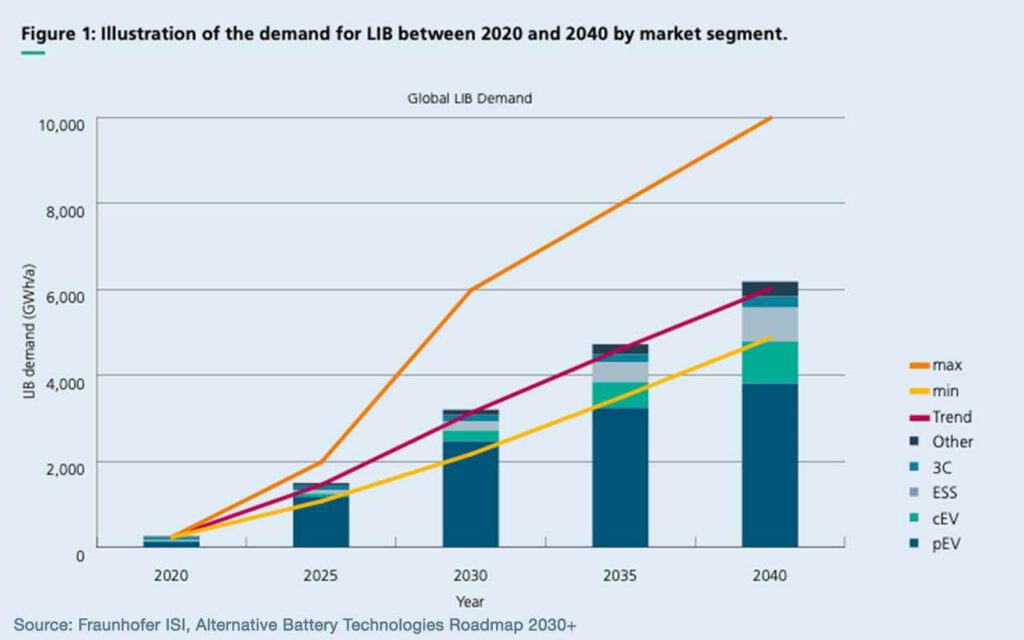

Aiming for 4,700 GWh by 2030

Batteries are a crucial component and essential in future scenarios for a sustainable energy supply, especially for electromobility and the storage of electricity produced from renewable sources. The energy storage market is expected to grow from 700 gigawatt hours in 2022 to 4,700 gigawatt hours in 2030, which will necessitate the supply of significant amounts of raw materials in addition to battery production.

Why should one choose sodium over lithium?

Right now, sodium-ion batteries are a relatively new yet quickly developing technology from an industrial standpoint. In these batteries, sodium replaces lithium. Because sodium can be separated from broadly available substances like sodium chloride (such as sea salt), sodium is cheap and readily available.

Furthermore, sodium-ion batteries can be manufactured without cobalt, nickel, or lithium, which are not essential components. This not only increases sustainability but also reduces costs by eliminating the need for expensive copper foils used in lithium-ion batteries. Additionally, graphite anodes can be replaced with other carbon compounds derived from renewable raw materials.

Similar to what China is currently doing, Europe must move as quickly as possible to bring these sodium-ion batteries to the market. However, this new type of battery may not become a true mass product for a number of years because there is still a significant amount of optimization work that needs to be done before it can become a mass product.

New opportunities for sustainable battery technology

The focus of the four-volt sodium-ion battery project is the development and optimal coordination of anodes, cathodes, and electrolytes to realize a high-performance, cost-effective, and environmentally friendly sodium-ion battery. The main aim of the project is to present a high-performance cell in pouch format that achieves a specific energy of over 200 Wh/kg.

On the cathode side, the focus is on the development of high-voltage cathodes with four volts. The focus here is on the development of safe, high-voltage stable mixed phosphates made from polyanions. Simulations are used to determine the optimum composition of the transition metals used to maximize the stored energy. The anode is produced based on hard coal from biowaste, using primary products that are available in abundance in Germany. The electrolyte will be a non-aqueous liquid to which a so-called ionic liquid can be added to increase conductivity and safety. Strategies for pre-charging (pre-sodding) such batteries are also to be developed to maximize the energy in the battery.

Source: Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW), Germany