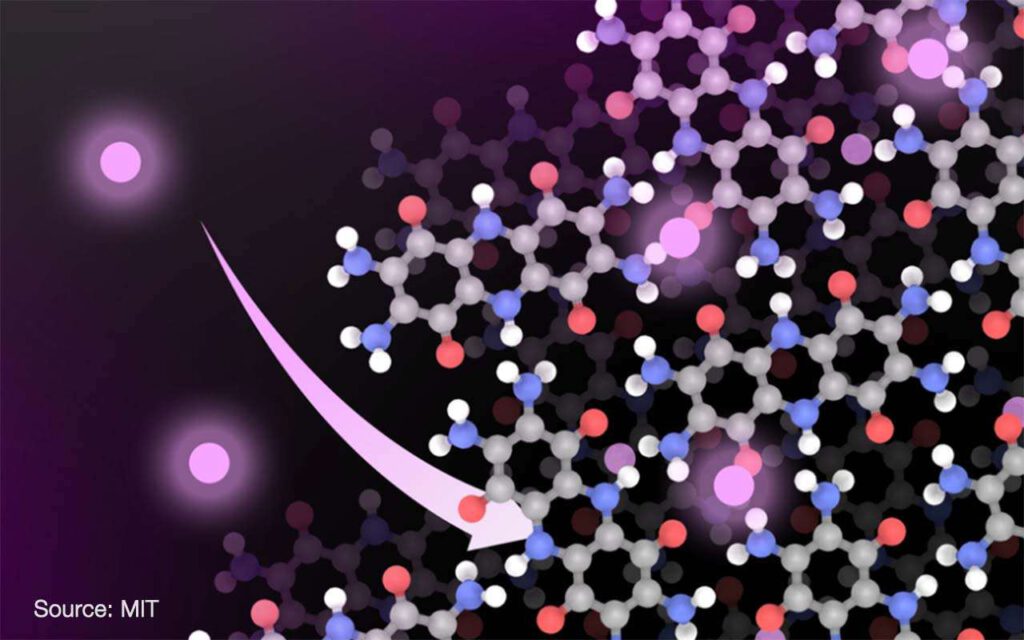

MIT researchers have developed a lithium-ion battery using an organic material-based cathode, a substantial departure from the industry’s previous dependence on metals such as cobalt and nickel. This innovation is a critical step toward minimizing the environmental and social implications of metal extraction and battery production.

Cathode Performance Metrics That Stand Out

Conventional lithium-ion batteries typically contain cobalt, which, despite its efficiency, has significant financial and environmental costs. The scarcity of cobalt, combined with its fluctuating prices and hazardous mining conditions, presents significant environmental and social challenges. The MIT team, led by Mircea Dincǎ, developed organic cathode materials derived from abundant elements. These materials offer a promising alternative to inorganic cathodes in lithium-ion batteries, overcoming issues such as poor conductivity and capacity.

Impressive Cathode Performance

The innovative layered organic neat TAQ cathode demonstrates high conductivity and storage capacity with a remarkable ability to reversibly intercalate lithium ions. It achieves a storage capacity of 306 mAh/g and an energy density of 765 Wh/kg, outperforming many cobalt-based cathodes. Notably, it can charge and discharge in just 6 minutes, marking a significant advancement in the practical application of sustainable organic materials in battery technology.

Addressing Social and Environmental Issues

Cobalt mining is known for its hazardous working conditions and pollution, making finding an alternative both a moral and environmental imperative. MITs new organic cathode is made of layers of TAQ (bis-tetraaminobenzoquinone), a substance that is stable and does not dissolve easily. This structure is critical since it prevents deterioration and increases battery life dramatically. The study presented a power capability and cycling stability report, keeping 88% capacity across 2000 cycles.

One of the most notable advantages of this battery is the abundance and affordability of the materials used. The use of more widely available organic materials instead of costly and rare cobalt could significantly reduce production costs while providing high-energy densities.

Expanding the Scope of Research and Application

This project, initiated with support from Lamborghini, is a testament to the power of collaboration between academia and industry. The involvement of researchers from MIT and the University of Bologna underlines the global dimension of this endeavor.

While lithium-iron-phosphate (LFP) batteries have been considered as alternatives, they fall short in energy density. The MIT-developed organic material, as detailed in the ACS Central Science publication, aims to match the efficiency of cobalt batteries without their drawbacks.

Reaching for a More Sustainable Future

Looking ahead, the MIT team is dedicated to exploring further alternatives to traditional battery materials. The focus is on replacing lithium with more abundant and cheaper elements like sodium or magnesium, aligning with global sustainability goals. The patent licensing by Lamborghini points to the immediate commercial potential of this technology. It’s a clear indicator of how these innovations are poised to make a significant impact on the EV industry.

Broader Implications and Continued Innovation

The study in ACS Central Science and MIT’s ongoing research underscore the wider implications of this technology. It’s not just about batteries, but also about contributing to the development of electric mobility and energy storage solutions more broadly.

Publication: A Layered Organic Cathode for High-Energy, Fast-Charging, and Long-Lasting Li-Ion Batteries, ACS Cent. Sci. 2024

Reference: MIT News