The electric vehicle (EV) market is rapidly evolving, with a growing emphasis on finding efficient and sustainable alternatives to lithium-ion batteries for automotive powertrains. The increasing demand for electric vehicles has highlighted the need for better battery technologies that overcome the limitations of current lithium-ion systems, such as limited charging infrastructure, slow charging speeds, and environmental concerns.

Key alternatives in battery technology

Lithium-ion batteries, while currently dominant due to their high-energy density, are facing several challenges. These include limited incremental improvements in technology, environmental and ethical issues related to lithium mining, and a growing global demand that may outstrip supply. This scenario has catalyzed a significant shift in the industry, with a surge of interest and investment in developing alternative battery chemistries.

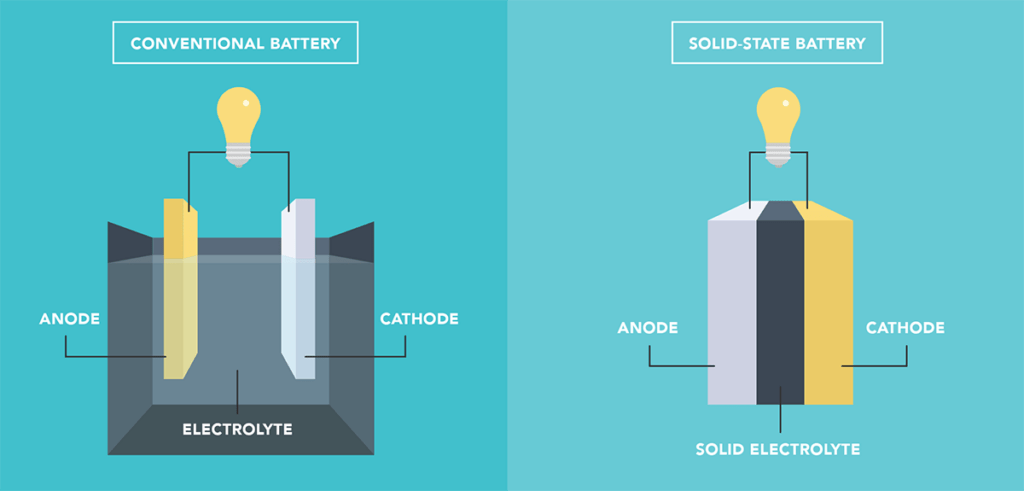

Solid-State Batteries

Solid-state batteries, employing solid electrodes and electrolytes, represent a significant advancement in battery technology, offering higher energy density, improved safety, and a longer lifespan compared to traditional lithium-ion batteries. They exhibit a range of specific energies, with thin-film types offering 300–900 Wh/kg and bulk types providing 250–500 Wh/kg. This variation implies a considerable advancement in energy storage capacity compared to traditional batteries [Ref.].

Solid-state batteries are increasingly being explored for use in electric vehicles, wearables, and other technologies, although challenges related to cost, temperature sensitivity, and manufacturing scalability remain. Some key players in this field include QuantumScape, Solid Power, Blue Solutions, ProLogium Technology, Hitachi Zosen Corporation, Factorial Energy, Electrovaya, Sakuu, ITEN, Cuberg, and SolidEnergy Systems. This battery technology is drawing considerable research and development investment from major automakers. Companies like Toyota and BMW are actively developing solid-state batteries, which use solid electrolytes instead of liquid ones. This shift is expected to result in safer, more efficient batteries that could revolutionize the EV market.

Sodium-Ion Batteries

As an abundant element, sodium presents a promising alternative to lithium in battery technology. BYD, a leader in EV production, is at the forefront of integrating sodium-ion batteries into their vehicles. These batteries have been shown to have comparable energy densities to some popular lithium-ion cells, such as LFP, and exhibit excellent performance in low temperatures. On average, they demonstrate a specific energy range between 75–200 Wh/kg and an energy density of 250–375 Wh/L. This is complemented by their notable cycle durability, enduring “thousands” of cycles, indicating a robust lifespan [Ref.].

As of late 2023, key players in the sodium-ion battery industry include Faradion Limited, Contemporary Amperex Technology Co. Limited (CATL), TIAMAT Energy, HiNa Battery Technology Co. Ltd, Altris AB, Northvolt, and Natron Energy Inc. Notably, CATL, a leading lithium-ion battery manufacturer, has also started mass production of sodium-ion batteries. These batteries boast several advantages, such as a high-energy density of up to 160 Wh/kg, the ability to charge to 80% in 15 minutes at room temperature, and more than 90% capacity retention at -20°C. They also exceed national safety standards and are suitable for various transportation and energy storage applications, especially in extreme low temperatures.

Lithium-Sulfur Batteries

Pioneered by companies like Saft, lithium-sulfur batteries offer faster charging and higher energy density compared to traditional lithium-ion batteries. They also pose a lower risk of thermal runaway, especially in extreme temperatures. A key characteristic of Li-S batteries is their high specific energy, with values reaching up to 450 Wh/kg [Ref.]. This is significantly higher than most lithium-ion batteries, making Li-S batteries particularly suitable for applications requiring lightweight and high-energy density, like aerospace and electric vehicles.

Stellantis and Lyten are notable companies investing in the development of lithium-sulfur batteries for EV applications. In addition, recent advancements have made lithium-sulfur dioxide cells, previously considered primary and non-rechargeable, a viable option for rechargeable batteries. These developments are significant, as they can lead to batteries with higher energy densities and improved cycle life.

Magnesium-Ion Batteries

Initially less attractive due to their lower energy density, magnesium-ion batteries are making strides in terms of performance. They boast a high volumetric energy density, and recent research has improved their overall energy density, making them a more feasible option for EVs. The development of these batteries could lead to lighter, smaller, and potentially more cost-effective battery solutions for electric vehicles.

Recent developments in next-generation battery technology have presented a quasi-solid-state magnesium-ion battery (QSMB) that overcomes the limitations of previous magnesium-ion batteries. QSMB may combine the benefits of aqueous and non-aqueous systems. In studies, it demonstrates an energy density of 264 Wh/kg and operates effectively at subzero temperatures (−22°C), retaining 90% capacity after 900 cycles [Ref.].

Aluminum-Air Batteries

Aluminum-air batteries (AABs) have high theoretical energy densities and are considered a promising alternative to lithium-ion batteries, especially due to aluminum’s light weight, safety, abundance, and higher charge transfer per ion. However, their development faces significant challenges, such as the formation of an aluminum hydroxide surface barrier, high corrosion rates, and self-discharge issues, which are being addressed using alloying techniques and electrolyte modifications [Ref.].

While Aluminum-air batteries have great potential due to their high-energy density and use of abundant materials, current technology requires further development to overcome issues like anode corrosion and efficient rechargeability.

Metal-Oxygen Batteries

This category of batteries, including types like lithium-air, has recently been re-evaluated for their potential as rechargeable batteries. These batteries offer high specific energies, and ongoing research is focused on improving their rechargeability and cycle life. The development of metal-oxygen batteries could lead to significant advancements in energy storage for EVs.

Battery Technology Outlook

The exploration of these alternative battery technologies is not solely driven by the scarcity of lithium. It also aims to achieve higher energy densities, faster charging rates, and greater environmental sustainability. As battery technology continues to advance, it has the potential to significantly alleviate range anxiety associated with EVs and transform the landscape of electric vehicle charging infrastructure. The coming years will likely see significant progress and breakthroughs in various battery chemistries, paving the way for a more diverse and sustainable electric vehicle industry.