6K is advancing the domestic production of critical minerals in the United States by utilizing a novel microwave plasma technology developed at MIT. The company, founded by former MIT research scientist Kamal Hadidi, aims to mitigate the environmental challenges associated with traditional production methods that generate toxic byproducts.

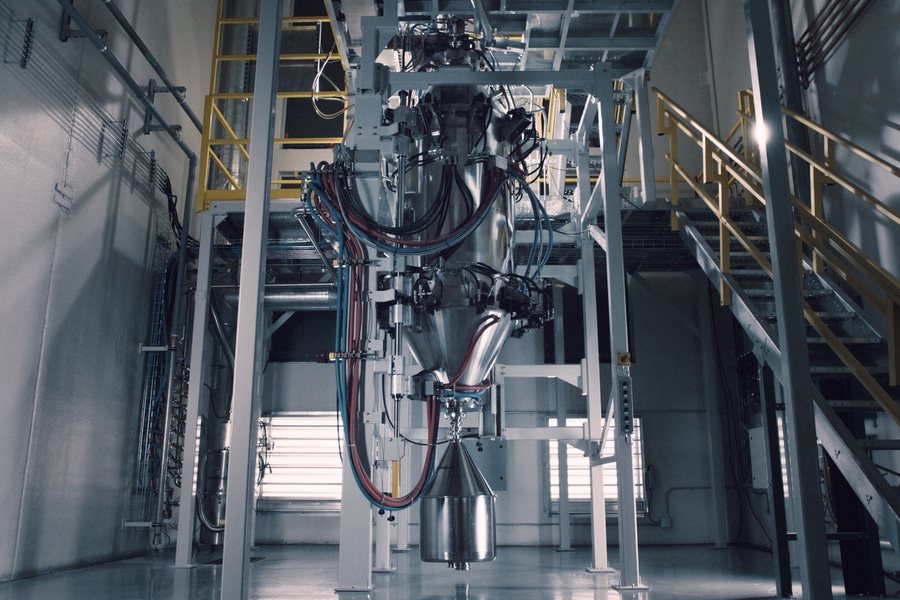

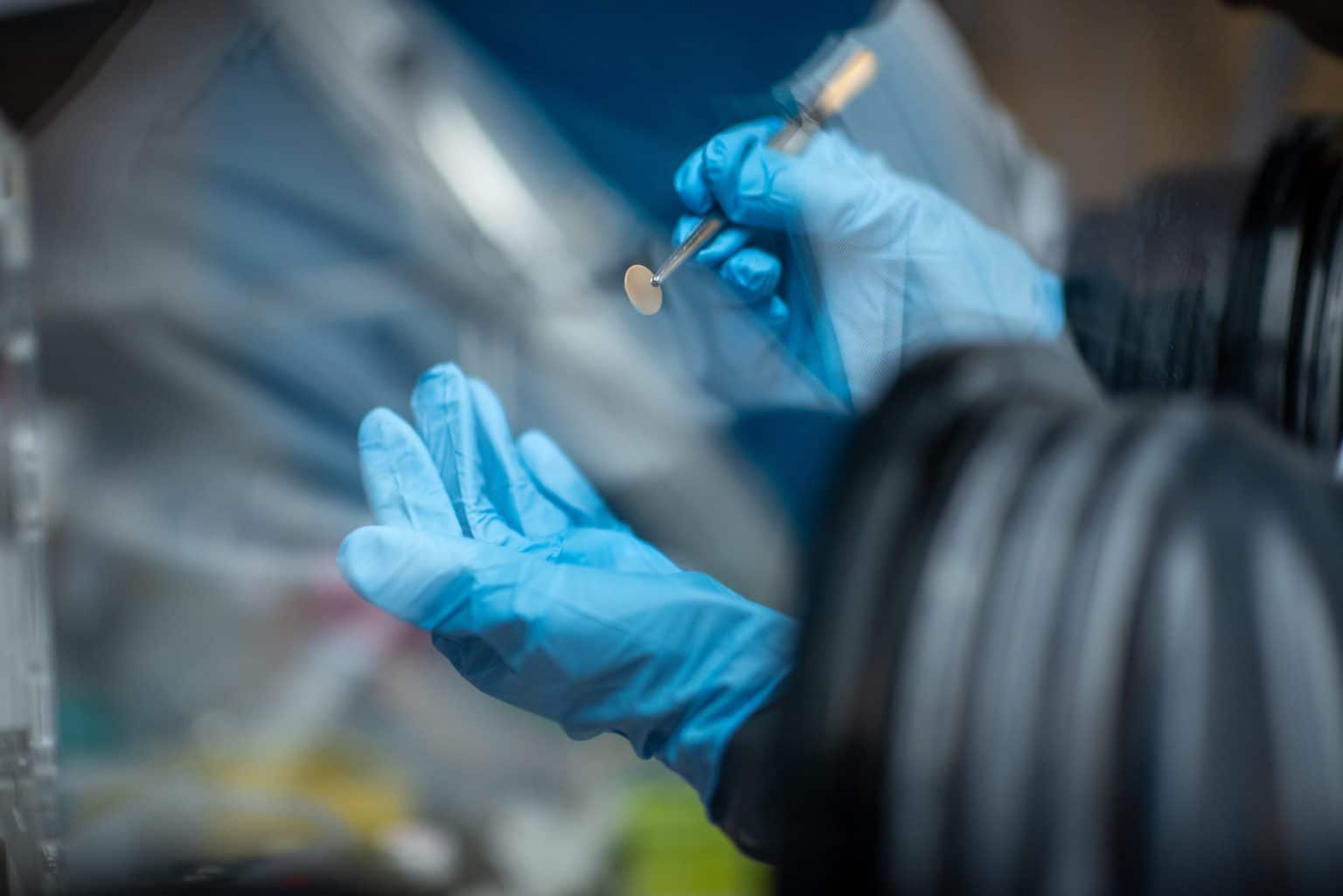

In an effort to revitalize U.S. manufacturing, 6K is scaling its proprietary UniMelt technology, which employs tightly controlled thermal plasma beams to melt or vaporize precursor materials into particles with precise sizes and crystalline structures. This innovative process is applicable to metals such as titanium, nickel, and refractory alloys, optimizing them for additive manufacturing across various industrial sectors. Additionally, UniMelt is being utilized to produce battery materials essential for electric vehicles, grid infrastructure, and data centers.

Saurabh Ullal, CEO of 6K, emphasized the strategic importance of the technology for both economic growth and national security. “The markets and critical materials we are focused on are important for not just economic reasons but also U.S. national security, because the bulk of these materials are manufactured today in nonfriendly countries,” Ullal stated. He highlighted that the technology, originally developed at MIT, enables the U.S. to reduce dependency on foreign sources and achieve supply chain independence.

6K’s production capabilities currently include a facility in Pennsylvania for additive manufacturing and a 33,000-square-foot battery center in North Andover, Massachusetts. The company is also constructing a 100,000-square-foot facility in Jackson, Tennessee, slated to begin later this year, which will significantly increase its battery materials production capacity to 13,000 tons annually once completed.

The company’s microwave plasma technology offers several advantages over conventional methods, including the reduction of high-energy steps and the ability to process recycled feedstocks for certain critical minerals. These advancements align with 6K’s commitment to environmental sustainability and the creation of circular economies.

6K recently secured a $23.4 million Defense Production Act grant to expand its processing capacity, aiming to double its output within the next three years. Additionally, the company received a grant to develop recycling processes for critical materials from military depots, supporting the production of aerospace and defense products and minimizing waste.

Kamal Hadidi, the founder of 6K, has a history of developing plasma technologies at MIT’s Plasma Science and Fusion Center, which have applications ranging from hydrogen production to environmental toxin detection. His collaboration with Professor Eric Jordan of the University of Connecticut led to the patenting of the UniMelt technology, which has proven to be a more efficient and environmentally friendly alternative for producing specialized materials.

6K continues to explore the potential of its technology to create specialty ceramics, advanced coatings, and nanoengineered materials, with ongoing research into eliminating PFAS chemicals.

Source: MIT News