Talga Group Ltd has announced a non-binding Memorandum of Understanding (MOU) with Altilium to ensure a sustainable supply of recycled graphite for electric vehicle (EV) battery anodes. Under the agreement, Altilium intends to provide Talga with up to 16,000 tonnes of recycled graphite over a three-year period starting in 2026.

Talga, listed on the Australian Securities Exchange (ASX), is developing Europe’s first natural graphite anode refinery in Sweden. The company is also working on a recycled graphite anode product to meet the growing demand for this essential material in EV batteries. Graphite constitutes 25-30% of an EV battery’s weight, and with the rapid adoption of electric vehicles, global graphite demand is projected to increase by 250% between 2023 and 2030. This surge is expected to create a supply deficit of approximately 777,000 tonnes by 2030.

Currently, over 90% of the world’s graphite is refined in China. In 2023, China implemented export controls on graphite, highlighting the need for innovative recycling methods to secure domestic supplies of high-quality graphite necessary for lithium-ion battery production. Developing a circular economy for graphite materials not only addresses supply concerns but also reduces waste and lowers carbon emissions compared to traditional mining practices.

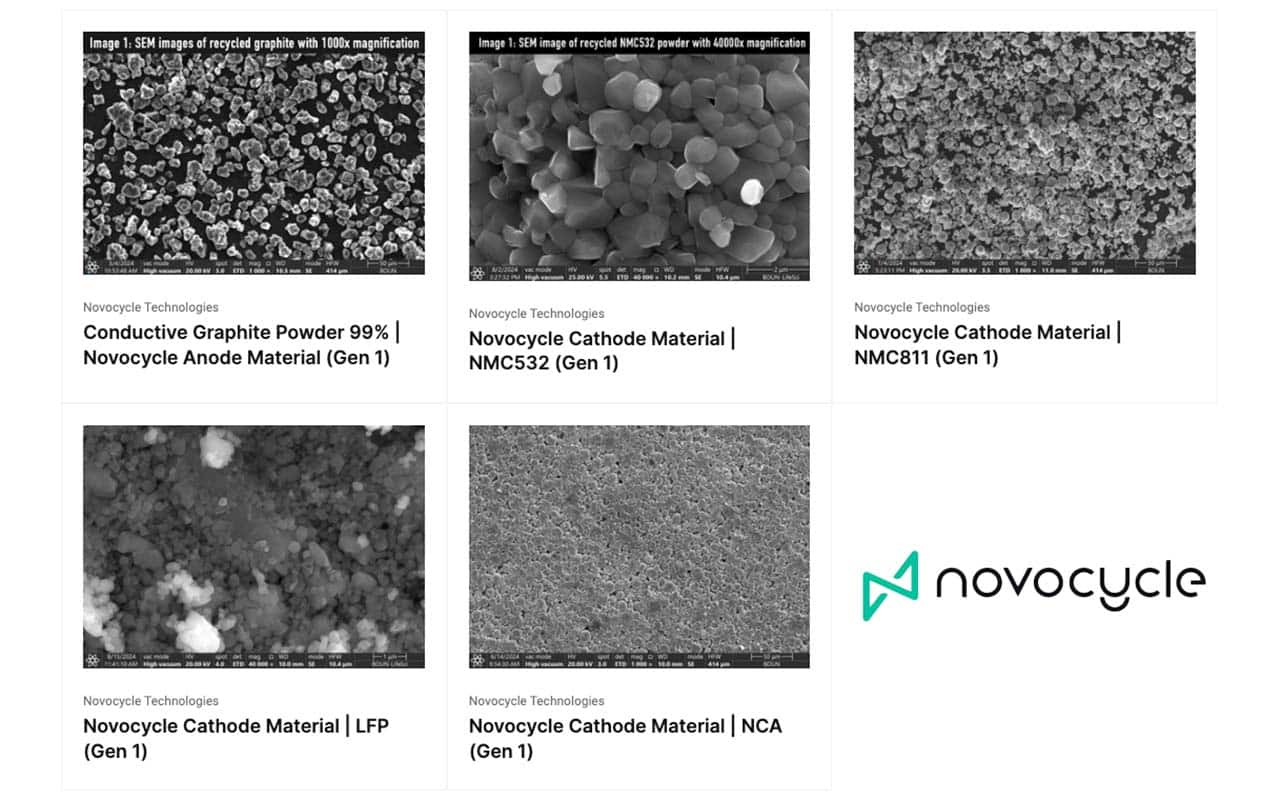

Altilium utilizes its EcoAnode™ process to recover 99% of graphite from end-of-life EV batteries. Initial testing has demonstrated that the recycled graphite achieves purity and physical characteristics comparable to primary graphite sources. Furthermore, the EcoAnode™ process results in a 77% reduction in greenhouse gas emissions compared to primary graphite production in China.

Altilium’s planned large-scale battery recycling facility in Teesside is expected to recover 20,000 tonnes of graphite annually, which would satisfy over 20% of the UK’s graphite demand by 2030. This initiative aligns with the European Union’s sustainability objectives, including the Critical Raw Materials Act. The Act sets a target for the EU to source 25% of its strategic raw materials from recycled sources by 2030.

The collaboration between Talga and Altilium supports the EU’s goals for sustainability and resource security, positioning both companies to meet the increasing demand for sustainable materials in the electric vehicle sector. By leveraging advanced recycling technologies, the partnership aims to contribute to a more resilient and environmentally friendly battery supply chain.

Source: Altilium