BASF has opened a prototype metal refinery in Schwarzheide, Germany, to refine raw materials from old batteries and production waste. The pilot plant will focus on optimizing technologies for recovering valuable metals such as lithium, nickel, cobalt, manganese, and copper. These technologies will be later utilized in a larger, commercial-scale recycling facility planned for Europe.

Battery Recycling and CAM Production in Schwarzheide

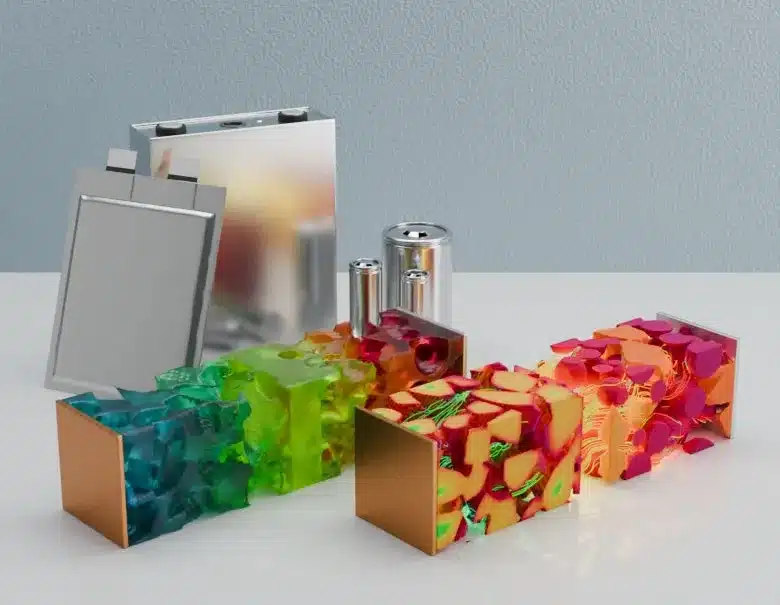

The refinery in Schwarzheide also houses BASF’s cathode material production, creating a synergistic hub for battery material production and recycling. Later this year, the battery recycling plant will begin producing ‘black mass’ – a combination of valuable metals obtained by shredding and processing used batteries and production waste. The metal refinery will then process this black mass to separate the valuable metals.

Dr. Daniel Schönfelder, President of BASF’s Catalysts division, emphasized the importance of recycling batteries for sustainable and competitive access to critical metals needed for electric vehicle batteries. This not only supports local economies but also significantly reduces CO2 emissions.

Related news

- Northvolt decides to build a battery factory in Heide, Germany

- VW Group UK teams up with Ecobat to recycle EV batteries

Setback in Finland

Persistent bureaucratic delays and legal uncertainties in Finland have led BASF to announce staff reductions at its Harjavalta battery materials production facility. Despite initial approvals, the facility, which was announced in 2018 and built adjacent to the MMC Norilsk Nickel nickel-cobalt plant, has struggled to commence operations. It was designed to begin production by the end of 2020 but was stalled by difficulties in securing an environmental permit.

As a result, BASF has terminated its plans to construct a precursor factory in Finland that was intended to manufacture cathode material precursors. Due to severe delays, BASF is now relying on other suppliers to maintain production in Schwarzheide.

Strategic Importance for Europe

The initiative is in line with the EU Battery Regulation, which aims to increase Europe’s self-sufficiency in critical battery materials and support the European Green Deal by reducing dependence on non-European raw material sources. BASF intends to expand its recycling operations into a commercial-scale refinery, although specific details about the location and timeline have not been disclosed yet.

Source: BASF News Release

Recommended: