The Fraunhofer Research Institution for Battery Cell Production (FFB) has launched the KOOP project in collaboration with RWTH Aachen University’s Chair of Production Engineering of E-Mobility Components (PEM) and mixing technology provider hs·tumbler. Supported by the German Federal Ministry of Research, Technology and Space, the three-year initiative seeks to speed up the transition of innovative production and battery technologies from laboratory research to industrial application.

Central to KOOP is the “Highly Cooperative Scaling” methodology, jointly developed by PEM and Fraunhofer FFB. This approach addresses common delays encountered at intermediate technology readiness levels by promoting coordinated financing, data sharing, and process scaling strategies.

“Challenges in knowledge and data transfer, as well as previously uncoordinated financing and scaling strategies, lead to idle times ranging from six months to several years,” says FFB Director Professor Achim Kampker.

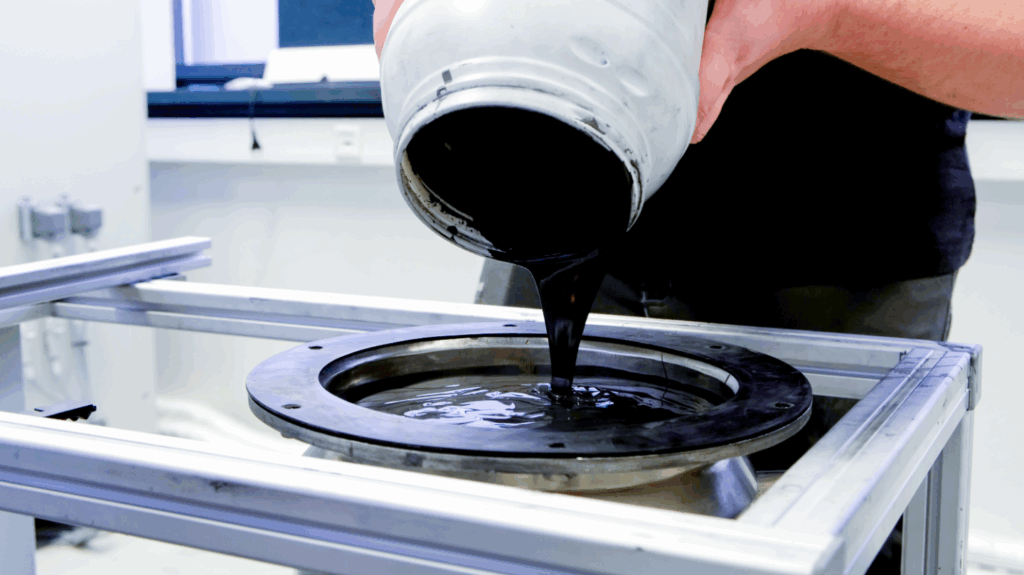

As a concrete demonstration, the partnership will focus on product and process development for a sodium-ion battery featuring a hard carbon anode manufactured via trajectory mixing. Industry partner hs·tumbler will provide its specialized trajectory mixers for this application.

During the project kick-off meeting at BatteryCityMünster, participants toured the FFB PreFab facility and outlined collaborative steps to integrate the new mixing technology into pilot production.

“Sodium-ion technology has enormous potential to reduce our dependence on critical raw materials while promoting sustainable battery cell production in Europe,” says Dr. Moritz Schaefer, research associate at Fraunhofer FFB. “Through highly cooperative scaling, we are creating the conditions to transfer this future technology from the laboratory to industrial application more quickly.”

By offering a blueprint for Highly Cooperative Scaling, KOOP is expected to cut energy consumption in the mixing process by at least 50 percent compared to conventional methods. The partners intend for the project to serve as a model for future collaborations that accelerate the industrialization of next-generation battery technologies.

Source: Fraunhofer FFB Press Release