Redwood Materials has developed an end-to-end battery supply chain that recovers and recycles critical minerals from end-of-life electric vehicle (EV) batteries, keeping them in circulation to support the energy transition. The company currently processes more than 20 gigawatt-hours of batteries each year—equivalent to the packs from roughly 250,000 EVs—and accounts for about 90 percent of all lithium-ion batteries recycled in North America.

Through a nationwide logistics network and proprietary sorting and recycling infrastructure, Redwood safely manages EV pack collection and evaluates each unit’s remaining capacity. Many packs retain over 50 percent of their original capacity, offering an opportunity for second-life applications before final mineral recovery.

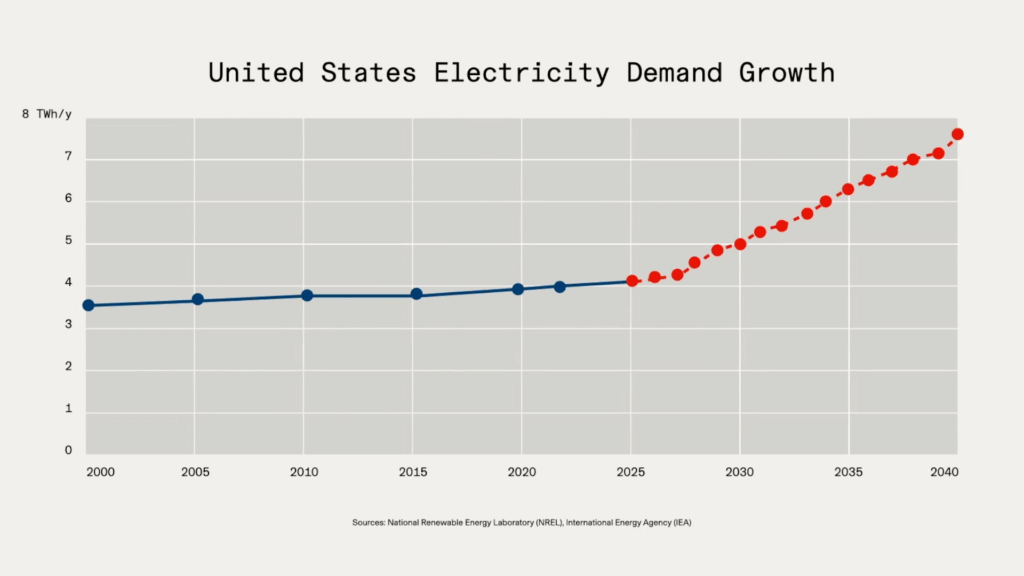

To bridge today’s gap in affordable, large-scale energy storage, Redwood introduced Redwood Energy, a platform that repurposes partially depreciated battery packs into modular, utility-scale energy storage systems. These systems can operate independently or connect to the grid, helping to shave peak loads, increase resilience and store intermittent renewable energy for high-demand applications such as data centers. With electricity demand driven by artificial intelligence workloads and widespread electrification expected to surge, data centers alone could consume up to 12 percent of U.S. power by 2028. Conventional grid expansion and new imported storage solutions struggle to match the speed, scale and cost requirements—challenges Redwood Energy aims to address.

Battery energy storage is essentially a commodity: the key metrics are reliability and cost per kilowatt-hour. By reusing EV batteries that no longer meet vehicle specifications, Redwood lowers material costs and accelerates deployment timelines compared to new lithium-ion projects. The company’s four-step workflow includes pack collection and storage, advanced diagnostics, modular integration across chemistries and end-of-life recycling for true circularity.

Redwood Energy has already deployed a 12 MW/63 MWh microgrid—North America’s largest second-life battery installation—powering Crusoe’s modular data center in Texas at below-grid cost. With over one gigawatt-hour of reused batteries in its pipeline and an additional five gigawatt-hours expected next year, Redwood is designing 100 MW-plus projects to meet growing power demands of the AI era and beyond.

Source: Redwood Materials