The BMW Group has announced plans to build a new battery cell recycling competence center in Kirchroth, located in the Lower Bavarian district of Straubing-Bogen. The facility will implement a direct recycling process, enabling the mechanical dismantling of residual materials from battery cell production and whole battery cells into their valuable components.

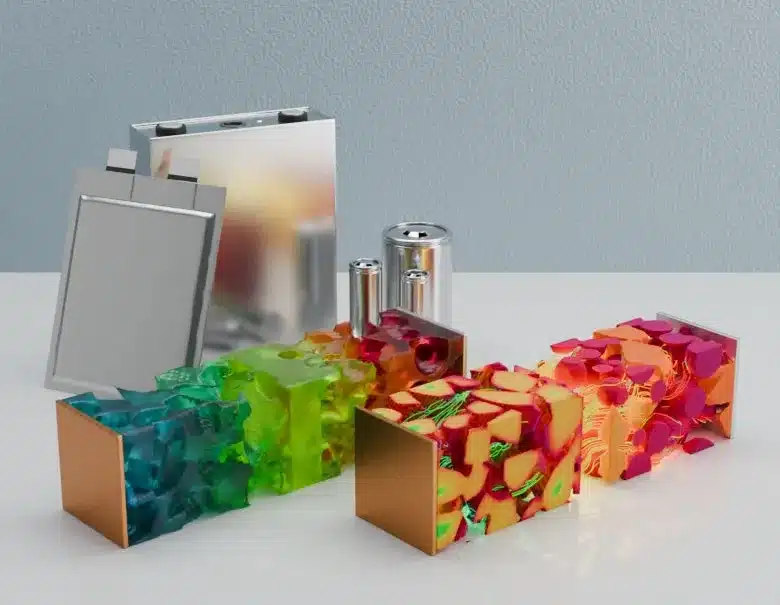

The recycled raw materials—including lithium, cobalt, graphite, manganese, nickel, and copper—will be directly reused in the pilot production of battery cells at BMW’s Battery Cell Competence Centers. This direct recycling method differs from conventional approaches by reintegrating raw materials into the cell production cycle without reverting them to their original state, thus eliminating the need for energy-intensive chemical or thermal processing.

“The new Cell Recycling Competence Center adds another element to our in-house expertise. From development and pilot production to recycling, we are creating a closed loop for battery cells, taking advantage of the short distances between our Competence Centers in Bavaria,” said Markus Fallböhmer, Senior Vice President of Battery Production at BMW AG.

BMW is investing approximately €10 million in the construction of the new recycling facility. Installation work is scheduled to begin in the second half of 2025, with validation of the recycling method in near-series processes set to commence upon completion. The center will cover an area of 2,200 square meters and will be integrated into the expansion of an existing building in the Kirchroth-Nord industrial park near Straubing.

While BMW owns the relevant intellectual properties, the facility will be operated by Encory GmbH—a joint venture between the BMW Group and the Interzero Group, with each holding a 50% stake. Encory specializes in developing and implementing logistics and consulting solutions in areas such as collection, recycling, and remanufacturing of vehicle components. The new competence center is expected to employ about 20 people once operational.