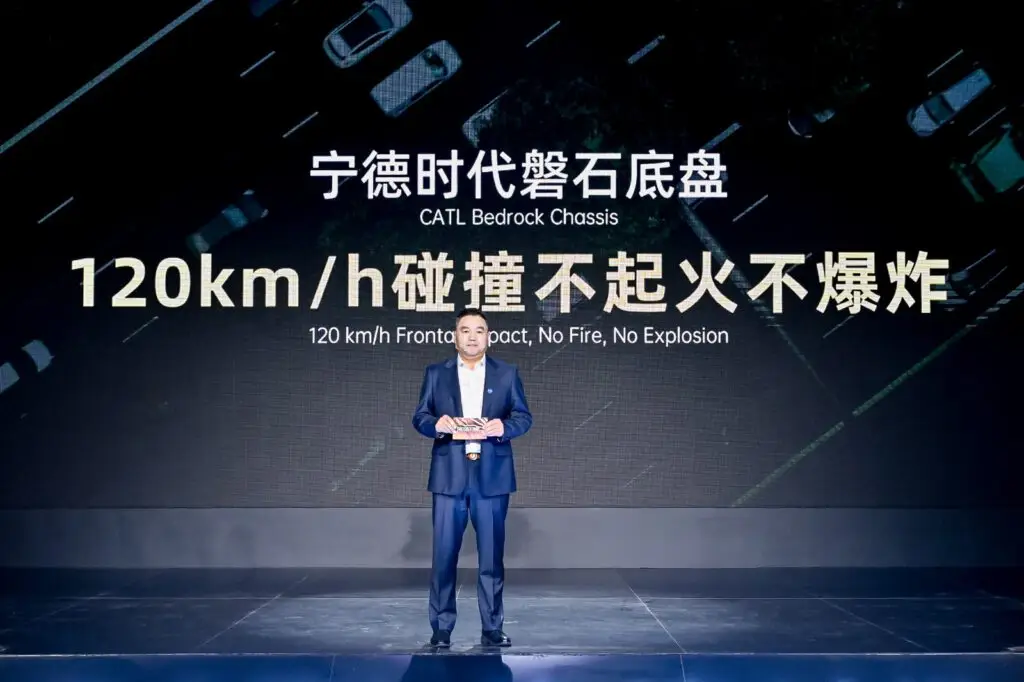

Contemporary Amperex Technology Co., Limited (CATL) has introduced the CATL Bedrock Chassis, heralded as the world’s first ultra-safe skateboard chassis for electric vehicles. Officially launched on December 24, the innovative chassis is designed to withstand frontal impacts at speeds of up to 120 km/h without catching fire or exploding, setting a new industry standard for safety.

The Bedrock Chassis utilizes a battery-centered design through Cell-to-Chassis integration technology, which directly incorporates battery cells into the chassis structure. This integration allows the chassis to absorb approximately 85% of collision energy during impacts, compared to about 60% absorption by traditional chassis designs. The chassis successfully passed rigorous safety tests, including a 120 km/h frontal central pole impact test, without experiencing thermal runaway, fire, or explosion.

In standard safety testing like the China New Car Assessment Program (C-NCAP), frontal impact tests are conducted at 56 km/h. The Bedrock Chassis’s performance at 120 km/h represents a collision energy 4.6 times greater than that of the standard test, equating to the energy from a fall off a 56-meter-high building. The severe frontal pole crash tests simulate collisions with narrow objects like utility poles or trees, where the impact area is significantly reduced, increasing pressure exponentially. At 120 km/h, the impact pressure on the chassis is 21 times that of standard testing conditions.

Key technological advancements contribute to the chassis’s safety capabilities. The design incorporates a three-dimensional biomimetic tortoise shell structure that integrates the body and energy unit framework. An aircraft carrier-grade arresting structure disperses impact forces along multiple pathways, reducing the severity of intrusions into the cabin. Materials such as submarine-grade hot-formed steel with a strength of 2000 MPa and aerospace-grade aluminum alloy with a strength of 600 MPa enhance the chassis’s rigidity.

The Bedrock Chassis also features ultra-safe battery cell design, including NP technology and a high-ductility energy-absorbing insulation film. It achieves instantaneous high-voltage disconnection within 0.01 seconds of impact and completes residual energy discharge within 0.2 seconds. Battery cells have undergone demanding tests, such as high-speed sled impact tests at 60 km/h, 90-degree bending tests, and breakthrough sawing tests, without catching fire or exploding.

Beyond safety, the chassis promotes modular and intelligent vehicle design. Its architecture allows for internal integration, decoupling from the upper body, and external openness. This flexibility enables manufacturers to develop multiple vehicle models from a single chassis architecture, reducing development time from the traditional 36 months to as little as 12 to 18 months. The Bedrock Chassis supports advanced driving capabilities from Level 3 to Level 4 autonomous driving and provides adaptable interfaces for collaborative intelligent applications.

At the launch event, CATL announced a partnership with AVATR, the first automaker to utilize the Bedrock Chassis. This collaboration aims to enhance vehicle safety and quality, offering consumers a superior driving experience.

Source: CATL