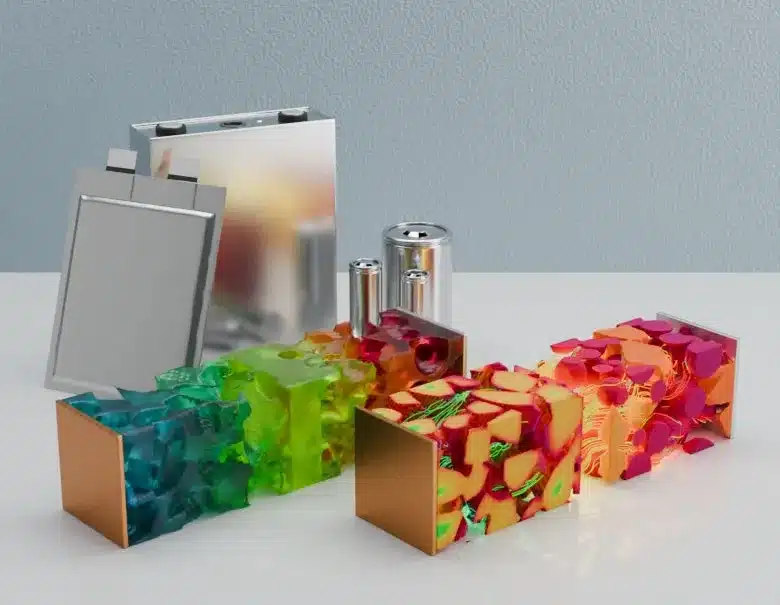

E3 Lithium Ltd. and Pure Lithium Corporation have entered into a joint development agreement to advance lithium metal battery technology in Alberta, Canada. The collaboration will utilize E3’s lithium brine resources and Pure Lithium’s Brine to Battery™ technology to develop an efficient production process for high energy density batteries.

Under the terms of the agreement, the companies plan to design a pilot plant near Calgary for the production of lithium metal anodes and batteries using E3’s lithium concentrate. Over the next 12 months, a techno-economic analysis will be conducted and joint scale-up efforts will continue. The pilot plant is expected to produce 200 kg of lithium metal anodes for use in vanadium rechargeable batteries.

This partnership builds on previous collaborative efforts, including the successful production of a lithium metal battery using E3’s lithium concentrate in June 2022. The resulting batteries have demonstrated higher energy density compared to conventional lithium-ion batteries and do not require nickel, cobalt or graphite.

Chris Doornbos, President and CEO of E3 Lithium, stated that the integration of E3’s direct lithium extraction process with Pure Lithium’s electrodeposition technology holds great promise for producing low-cost, sustainable batteries.

Emilie Bodoin, Founder and CEO of Pure Lithium, emphasized the importance of securing a reliable supply of lithium and noted that their partnership with E3 Lithium proactively addresses this challenge. The use of lithium concentrate in their production process is expected to reduce costs and improve battery performance.

Upon completion of the pilot project, the companies will evaluate the feasibility of developing a commercial-scale, vertically integrated lithium metal battery facility in Alberta. This initiative represents a potential step towards establishing a complete brine-to-battery production process in the region.

Source: BusinessWire