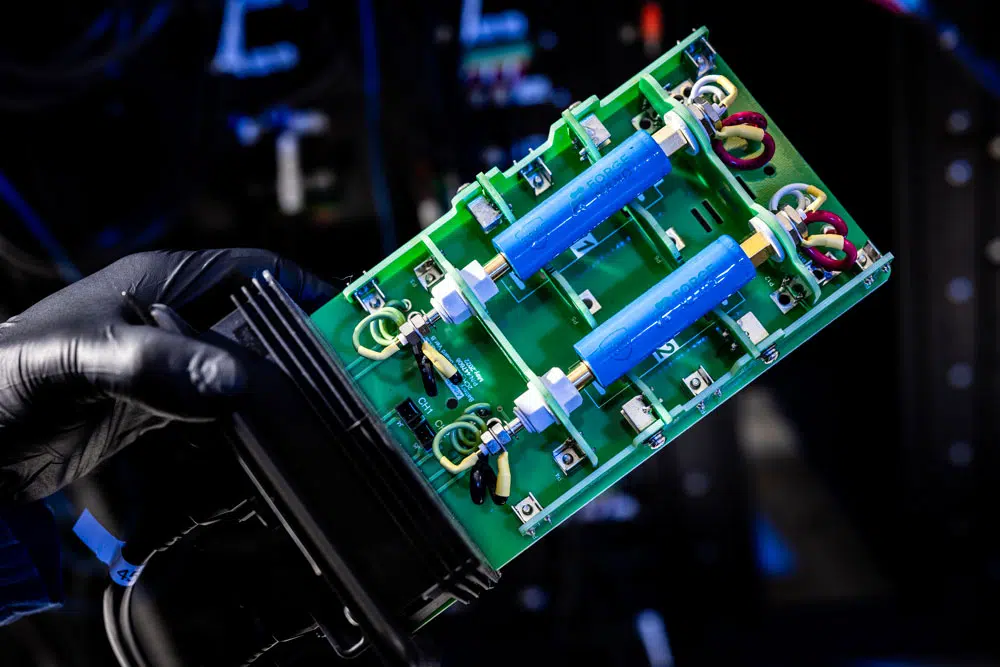

Forge Battery, a subsidiary of Forge Nano, Inc. specializing in commercial lithium-ion battery production, has begun shipping its groundbreaking high-energy 21700 cylindrical lithium-ion battery cells to existing customers and potential collaborators.

The company’s first commercial offering, the “Gen. 1.1 Supercell”, has successfully received UN 38.3 and UL 1642 certifications, confirming compliance with stringent safety standards and enabling shipment to customer facilities. Forge Battery expects to distribute thousands of cells throughout 2024 to current customers who have committed to multiple GWh/year of confirmed offtake. Following the announcement of the Morrisville Gigafactory in November 2023, the company has received Letters of Intent (LOIs) totaling 24 GWh/yr.

The Gen. 1.1 Supercell has a verified specific energy of 300 Wh/kg without compromising cycle life. These cells will undergo rigorous cycle life testing to meet various application-specific requirements of current and future customers. Forge Battery expects its A-sample cells to meet or exceed industry standard cycle life for target markets including electric trucks, off-highway vehicles, motorcycles, aerospace and Department of Defense (DoD) applications.

Featuring a lithium nickel manganese cobalt oxide (NMC 811) cathode and a silicon oxide (SiOx) graphite composite anode, the Forge Gen. 1.1 Supercell is expected to exceed the energy density targets set by the United States Advanced Battery Consortium (USABC) while achieving a 20% reduction in cost per kWh. These impressive performance metrics are achieved by incorporating high active silicon content and improved stability of cathode active materials at high voltage. Cost efficiencies are achieved through the reduction of electrolyte and electrolyte additives.

Forge Battery cell materials are enhanced using Forge Nano’s proprietary Atomic Armor atomic layer deposition technology. This innovative process applies an ultra-thin, uniform and robust nanocoating to materials, effectively preventing unwanted chemical reactions at the surface.

Commercial production of super-cells is expected to begin in 2026 at a newly constructed Gigafactory near Raleigh, North Carolina. Forge Battery aims to utilize a predominantly U.S.-sourced materials supply chain, with 90 percent of cell content sourced from U.S. companies. Currently, the Gen. 1.1 Supercell uses 100 percent U.S. cathode and anode materials, with additional cell materials sourced from South Korea.

With this technical progress, the performance of lithium-ion batteries has advanced significantly, enabling Forge Battery to successfully compete with global Tier 1 suppliers and offer American battery innovation on a worldwide scale.

Source: Forge Nano Newsroom