GreenRoc Strategic Materials plc and Morrow Batteries ASA have signed a non-binding Memorandum of Understanding (MoU) to collaborate on the development of graphite active anode material (AAM), a key component in advanced battery technology. The partnership aims to establish a sustainable Nordic battery value chain by supplying graphite from GreenRoc’s Amitsoq mine in Greenland to Morrow’s lithium iron phosphate (LFP) Gigafactory in Arendal, Norway.

The collaboration includes plans for co-locating GreenRoc’s AAM production facility at the Eyde Materials Park in Southern Norway, near Morrow’s cell manufacturing plant. This strategic proximity is expected to reduce transportation costs and lower carbon dioxide emissions, while ensuring consistent quality and supply security of graphite materials essential for battery production.

Jon Fold von Bulow, Chief Science Officer and Co-Founder of Morrow Batteries, stated, “Our collaboration with GreenRoc marks a significant step toward building a sustainable Nordic battery value chain. This partnership will be an important stepping stone in bringing the carbon emissions of our battery cells to exceptionally low levels while strengthening Europe’s battery supply security.”

Stefan Bernstein, CEO of GreenRoc, commented, “This partnership with Morrow marks a pivotal milestone in establishing a European graphite anode material supply chain. The strategic co-location of our facilities and shared commitment to ESG excellence create an ideal foundation for developing high-quality battery materials. Together, we can pioneer domestic European battery production while setting new industry standards.”

GreenRoc is establishing a Norwegian subsidiary, NorGraph AS, to develop the AAM plant and access European Union funding schemes. The Amitsoq project involves reopening a historic mining site using closed-pit operations to access one of the world’s richest graphite deposits. The deposit contains 23.05 million tonnes of ore with an average graphite grade of 20.41%, amounting to a total graphite content of 4.71 million tonnes. Test work has shown that Amitsoq graphite can be upgraded to high-grade, anode-quality material with purity exceeding 99.95%.

A Preliminary Economic Assessment released on October 31, 2023, indicates a post-tax Net Present Value (NPV) at an 8% discount rate of US$179 million

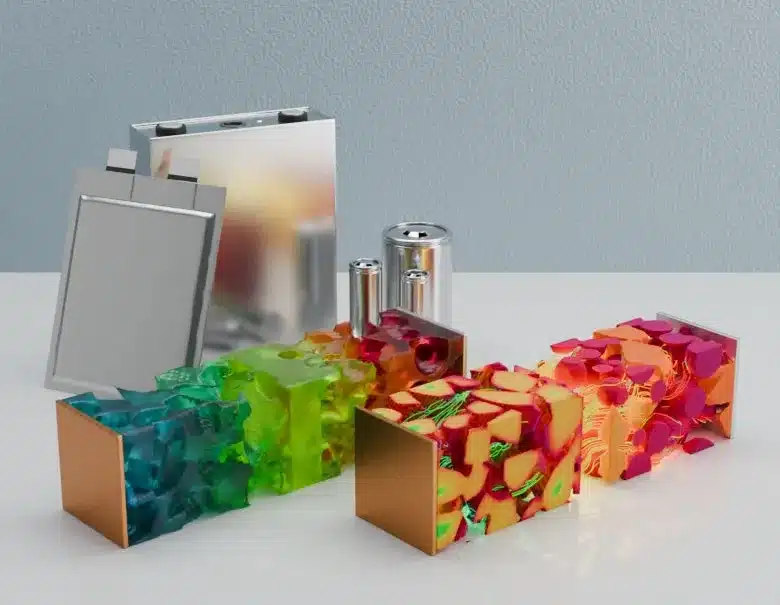

Source: MORROW Batteries