Lyten has advanced its efforts to strengthen the U.S. battery supply chain by commencing domestic production of battery-grade lithium-metal alloys and foils. This development establishes a fully U.S.-manufactured anode supply chain for Lyten’s Lithium-Sulfur batteries, which are designed to be a tariff-free alternative to traditional lithium-ion batteries. Since 2023, Lyten has been producing its Lithium-Sulfur batteries, including both cathodes and anodes, entirely within the United States. This is a significant departure from conventional lithium-ion batteries, where only a small fraction of cathode and anode components are manufactured domestically.

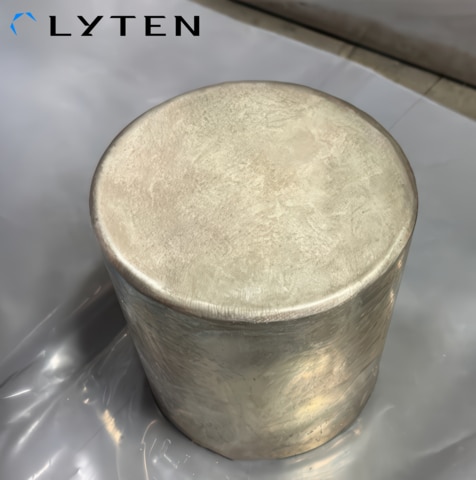

Located in San Jose, California, Lyten has produced the first battery-grade lithium-metal foil in the United States, utilizing locally sourced lithium alloys and lithium-metal. This initiative complements Lyten’s existing fully localized supply chain for its sulfur cathodes, resulting in a resilient and tariff-free battery supply chain. Lyten’s lightweight batteries are applicable in various sectors, including energy storage, electric vehicles (EVs), drones, satellites, micromobility solutions, and defense.

The initiative aligns with current U.S. policy directives and defense sector objectives that emphasize the need for increased domestic sourcing of critical materials and the expansion of the U.S. battery industry. Presently, the majority of batteries and essential critical minerals are imported from China, posing strategic vulnerabilities for the United States.

Dan Cook, Lyten Co-Founder and CEO stated, “To build a U.S. battery industry, we must solve the supply chain challenge. We have already eliminated the need for nickel, manganese, cobalt, and graphite with our Lithium-Sulfur battery, allowing us to focus on local supply and production of lithium. Lyten will be the only battery manufacturer in the U.S. shielded from tariffs and critical minerals risk.”

“Lithium is abundantly available across the United States, but the capacity to process lithium into battery grade materials is extremely limited in the U.S. Being able to design and process our own lithium-metal alloys and foils is a game changer and puts Lyten at the front edge of U.S. battery manufacturing, especially for next generation Lithium-Sulfur battery technology,” said Celina Mikolajczak, Lyten Chief Battery Technology Officer.

Lyten has partnered with Creative Engineers, Inc. in Pennsylvania to produce proprietary lithium alloys and is sourcing lithium-metal from an Eastern U.S. facility. The lithium-metal is then transformed into proprietary foils at Lyten’s San Jose facility, which boasts one of the largest lithium foil extrusion and rolling capacities in North America.

The company is also scaling its production capabilities by acquiring Northvolt’s battery manufacturing plant in San Leandro, California. Furthermore, Lyten has secured a $650 million letter of intent with the Export-Import Bank of the United States to support the expansion and delivery of its Lithium-Sulfur batteries for energy storage systems. Upcoming projects include integration into Chrysler’s Halcyon Concept electric vehicle, partnership with AEVEX Aerospace for unmanned aerial vehicles, and a demonstration on the International Space Station scheduled for 2025.

Source: Business Wire