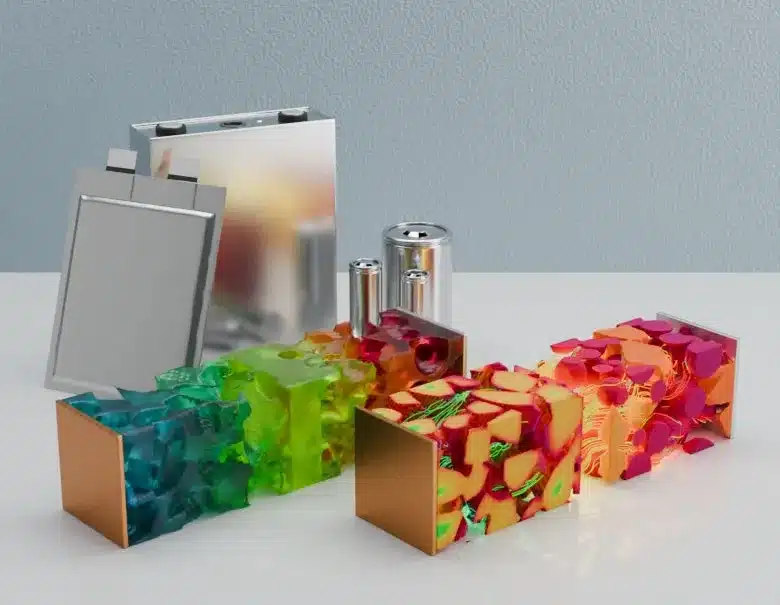

Mercedes-Benz has commenced operations at its inaugural battery recycling plant in Kuppenheim, Germany. The facility employs an integrated mechanical-hydrometallurgical process to recover valuable materials from used electric vehicle batteries, achieving a recycling rate of up to 96%. This positions Mercedes-Benz as the first automaker globally to close the battery recycling loop within its own operations.

Traditional battery recycling often involves discharging, dismantling, and crushing used batteries to produce a mixed “black mass” of active materials, which is then processed elsewhere. In contrast, the Kuppenheim plant processes this black mass on-site using hydrometallurgical methods. Operating at temperatures up to 80 degrees Celsius, this energy-efficient process consumes less energy and produces less waste compared to conventional pyrometallurgical techniques.

Currently, the plant has an annual capacity of 2,500 tonnes, sufficient to process over 50,000 battery modules for all-electric models. Mercedes-Benz plans to scale up production and expand recycling capacities as more recyclable batteries become available in the future.

The opening ceremony was attended by Mercedes-Benz CEO Ola Källenius, Supply Chain Management Board Member Jörg Burzer, German Chancellor Olaf Scholz, and Baden-Württemberg’s Environment Minister Thekla Walker. Chancellor Scholz highlighted the significance of the facility, stating, “The circular economy is a growth engine and an essential building block for achieving our climate targets. Germany remains a cutting-edge market for new and innovative technologies.”

Ola Källenius remarked, “Europe’s first integrated mechanical-hydrometallurgical battery recycling factory marks a key milestone towards enhancing raw-material sustainability. We are sending a strong signal of innovative strength for sustainable electric mobility and value creation in Germany and Europe.”

Jörg Burzer added, “The innovative technology enables us to recover valuable raw materials with the highest possible degree of purity. This turns today’s batteries into tomorrow’s sustainable mine for raw materials. The new battery recycling plant strengthens the role of the Mercedes-Benz production network in Europe.”

The Kuppenheim facility operates on a carbon-neutral basis, supplied entirely with green electricity. The 6,800-square-meter building features a rooftop photovoltaic system generating over 350 kilowatts of power.

This initiative follows the opening of the Mercedes-Benz eCampus in Stuttgart-Untertürkheim, where the company is consolidating its battery research efforts. The eCampus focuses on developing high-performance battery cells and new production processes, aiming to reduce battery costs by more than 30%.

Source: Mercedes-Benz Media