Researchers at Martin Luther University Halle-Wittenberg (MLU) have developed a gel filling for lithium-ion batteries that aims to improve safety and performance. The gel is designed to prevent leakage of the flammable electrolyte fluid, addressing a common safety concern in conventional lithium-ion batteries.

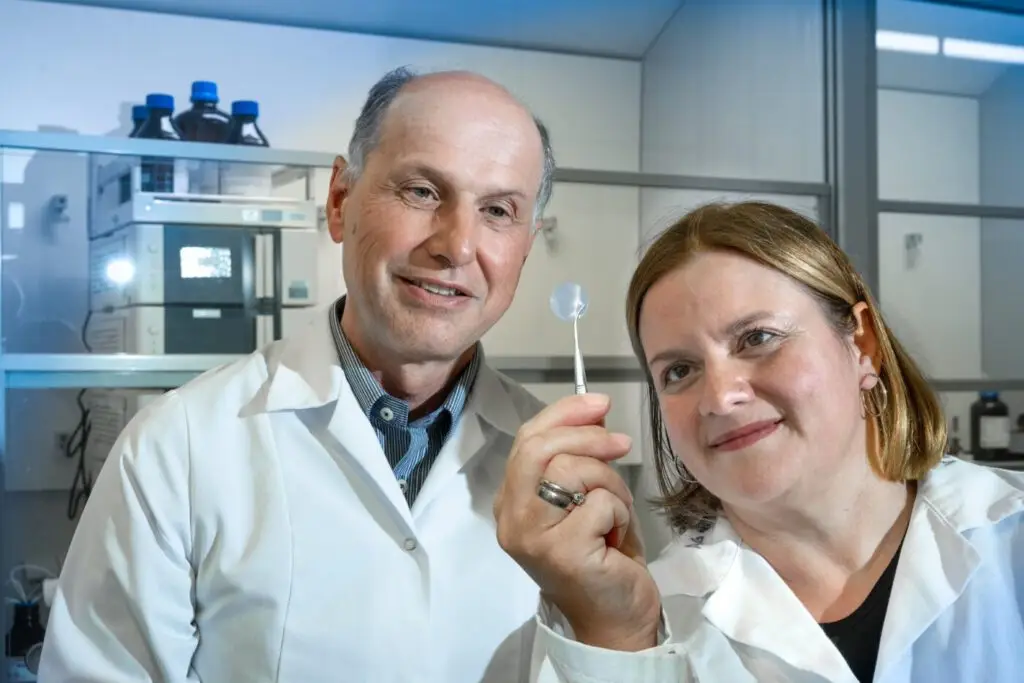

The research team, led by Professor Wolfgang Binder of MLU’s Macromolecular Chemistry Research Group, has developed a polymer for integration into battery cells. This polymer binds the electrolyte while allowing ions to move between the electrodes, maintaining the battery’s functionality.

Dr. Anja Marinow, an MLU chemist, describes the filler as having properties that combine liquid conductivity with polymer stability. The researchers addressed the challenge of creating a stable electrode layer by incorporating an ionic structure into the polymer’s molecular composition.

Laboratory tests have shown promising early results. The gel electrolytes demonstrate stability at voltages above 5 volts, exceeding the 3.6-volt stability threshold of conventional lithium-ion cells. This increased stability could contribute to improved battery performance and longevity.

The research also addresses sustainability issues by designing the gels for potential recycling in the event of failure or at the end of the battery’s life. However, extensive long-term studies are needed before industrial-scale production of these lithium-gel batteries can be considered.

This research was carried out as part of the ‘BAT4EVER’ project, funded by the European Commission’s Horizon 2020 program. The work involved collaboration between academic institutions, research centres and industrial partners from several European countries.

The study, “Designing Conductive Pyrrolidinium-Based Dual Network Gel Electrolytes: Tailoring Performance with Dynamic and Covalent Crosslinking,” was published in the journal Advanced Functional Materials. DOI: 10.1002/adfm.202403487