A recent study conducted by researchers at the U.S. Department of Energy’s Argonne National Laboratory has provided significant insights into the enhancement of solid-state battery safety through electrolyte doping. Published in ACS Materials Letters, the research explores how adding specific dopants to solid electrolytes can improve their interaction with lithium metal electrodes, potentially leading to safer and more energy-efficient batteries.

Solid-state batteries, which use solid electrolytes instead of the traditional liquid ones found in lithium-ion batteries, are gaining attention for their potential to offer higher energy density, longer lifespan, and improved safety. Unlike liquid electrolytes, solid electrolytes are non-volatile and non-flammable, addressing some of the major safety concerns associated with conventional batteries. A leading candidate for these solid electrolytes is lithium lanthanum zirconium garnet (LLZO), known for its strength, durability, and high ionic conductivity.

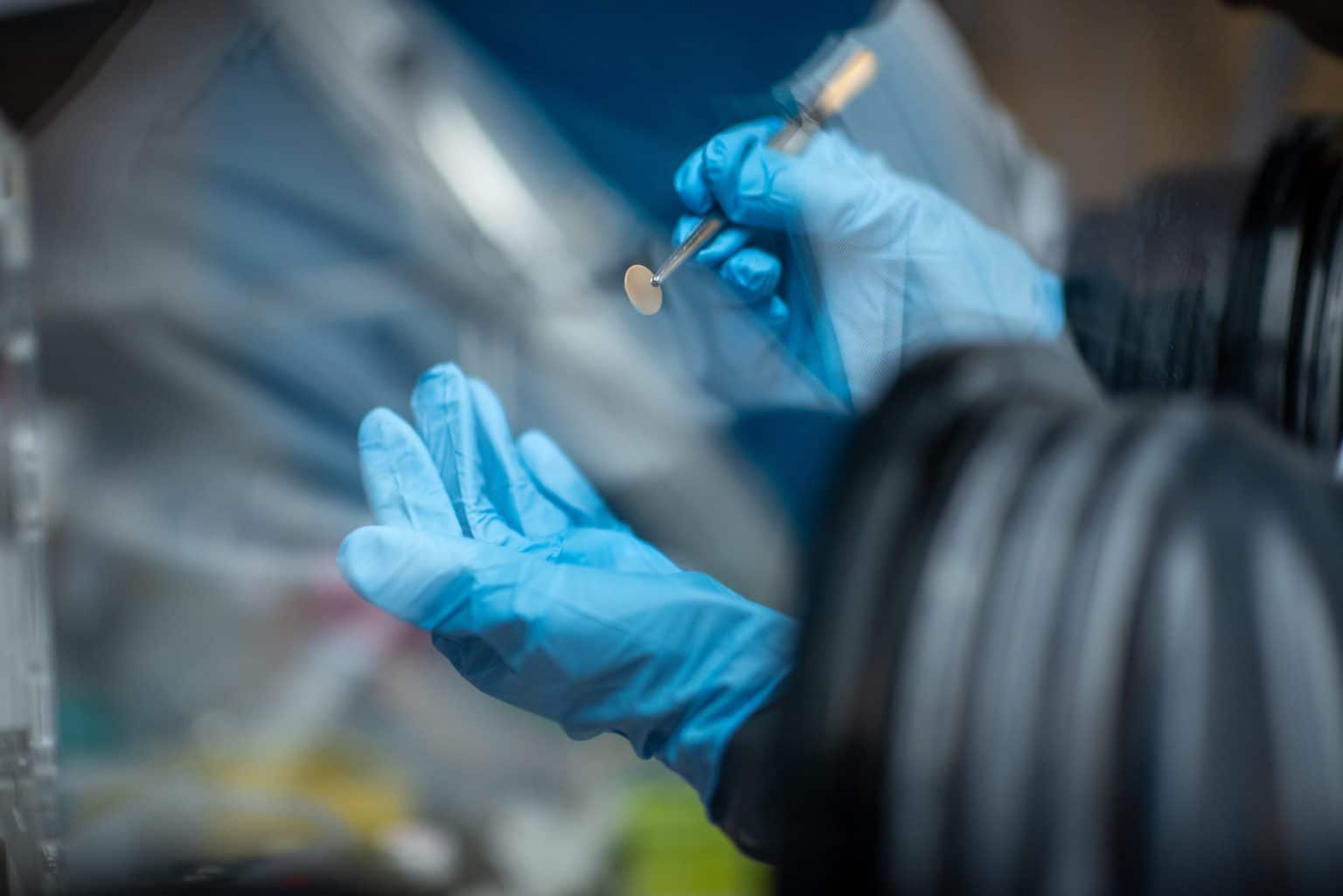

The research team focused on enhancing LLZO by doping it with elements such as aluminum and gallium. Doping involves introducing small amounts of another element to modify and improve the material’s properties. The addition of aluminum and gallium helps maintain the symmetric structure of LLZO and creates vacancies that facilitate the movement of lithium ions, thereby improving conductivity. However, this doping process also increases the reactivity of LLZO with lithium metal, which can reduce the battery’s cycle life.

Through a combination of computational and experimental methods, the study found that gallium-doped LLZO, while offering higher ionic conductivity, tends to react more readily with lithium, leading to the formation of an alloy and a subsequent decrease in conductivity. In contrast, aluminum-doped LLZO remained more stable when in contact with lithium metal, preserving its structure and conductivity over time. The research underscores the need for an interfacial layer to protect gallium-doped LLZO, maintaining its conductivity while preventing excessive reactivity.

Peter Zapol, a physicist at Argonne, emphasized the importance of understanding dopant interactions with lithium to develop effective solid electrolytes. The collaboration with institutions like the University of California, Santa Barbara, and facilities in Germany and the Czech Republic was crucial in obtaining high-quality LLZO and conducting neutron diffraction experiments.

The findings from this study contribute to the global effort to develop safer and more reliable solid-state batteries, which are expected to play a pivotal role in the future of electric vehicles and various portable electronic devices.