Panasonic Energy Co., Ltd., a Panasonic Group subsidiary, has reported completion of preparations for mass production of 4680 cylindrical automotive lithium-ion batteries. The company has remodeled its Wakayama factory in Western Japan to serve as the primary production facility for these new cells.

The 4680 cell format represents an advancement over the current 2170 cells, offering increased capacity and potential improvements in electric vehicle (EV) performance and cost-efficiency. Panasonic Energy states that the 4680 cells have five times the capacity of 2170 cells, which may contribute to extended EV range and streamlined battery pack assembly.

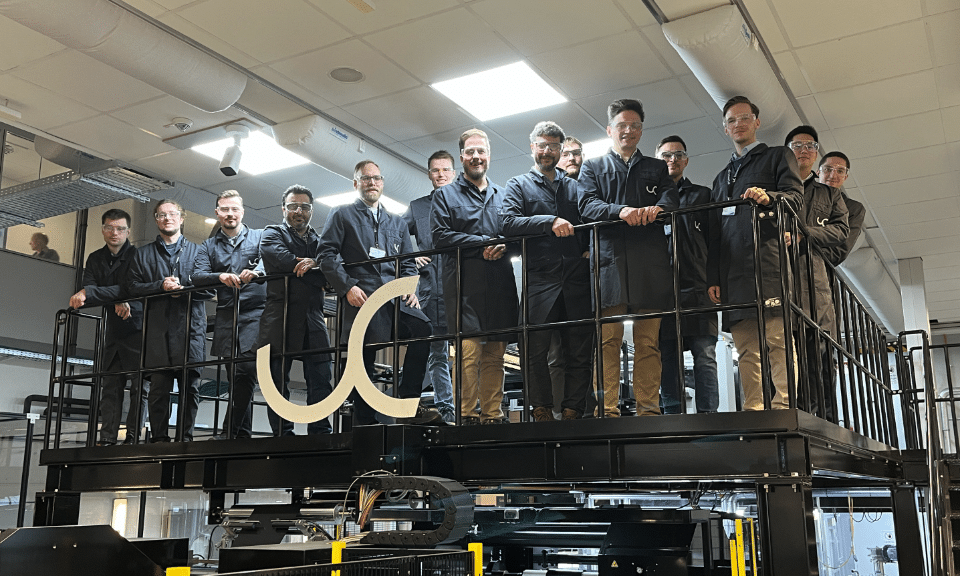

Drawing on three decades of experience in cylindrical lithium-ion battery technology, Panasonic Energy has developed mass production capabilities for the 4680 cells. The renovated Wakayama factory is designated as the lead facility for 4680 cell production and will function as a testing ground for new products and manufacturing processes. The company projects that by March 2025, approximately 400 employees will be engaged in next-generation battery development and production at this site.

Panasonic Energy is incorporating environmental considerations into its production plans. The Wakayama facility intends to maximize the use of renewable energy sources in its operations. This aligns with the company’s broader sustainability initiatives, which include achieving carbon neutrality across its nine domestic bases as of September 2024. Panasonic Energy aims to extend this to all 20 of its global facilities by March 2029.

The commencement of mass production for the 4680 cells is pending final evaluation. Panasonic Energy anticipates that the introduction of these cells will expand its product range and potentially contribute to increased EV adoption.

Source: Panasonic Energy – News Release