New research conducted by Imperial College London has demonstrated that Altilium’s recycled electric vehicle (EV) battery materials not only match but also exceed the performance of virgin mined materials. This development represents a significant advancement toward establishing a circular economy for EV battery components, highlighting the viability of recycled materials as high-performance alternatives to traditionally mined metals.

Imperial College’s comprehensive analysis of Altilium’s recycled cathode active materials (CAM) revealed notable enhancements in purity, morphology, and electrochemical performance compared to commercially available counterparts. These improvements are anticipated to lead to substantial gains in battery performance, including extended battery life, accelerated charging times, and reduced costs.

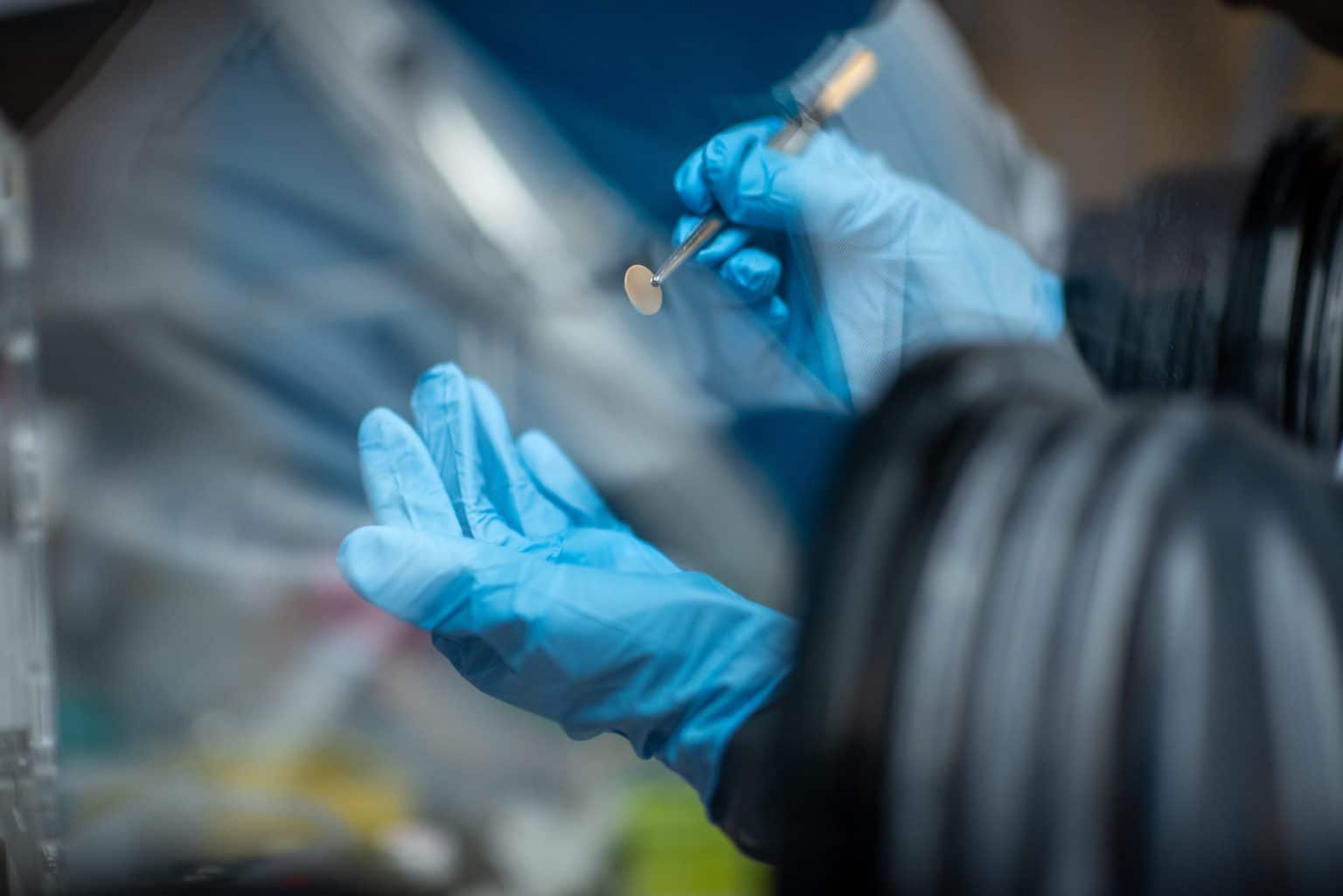

As part of the research initiative, Imperial conducted extensive electrochemical testing on both coin cells and pouch cells fabricated with recycled CAM produced at Altilium’s ACT1 facility in Devon. The findings indicated superior rate and cycle performance in Altilium’s materials relative to commercially available CAM used in high-nickel NMC 811 batteries. Specifically, with a cycle cell capacity surpassing 150 mAh/g, Altilium’s recycled materials significantly outperformed the typical ranges observed in mined materials.

Further analysis of the recycled CAM samples unveiled significant advancements in particle size and distribution, which contribute to enhanced stability and cycling behavior. Minor changes observed during testing affirmed the chemical and physical robustness of the recycled CAM, underscoring its potential for sustained long-term battery performance.

The results highlight the effectiveness of Altilium’s proprietary EcoCathode™ process, capable of recovering over 95% of critical metals, including lithium, from end-of-life EV batteries. By upcycling these materials into high-quality CAM, Altilium provides UK cell manufacturers and automotive original equipment manufacturers (OEMs) with a sustainable domestic source of high-performance battery materials. This approach supports the achievement of net-zero targets and reduces the UK’s dependence on imported virgin materials.

The technical superiority of recycled CAM over virgin CAM stems from the inherent properties of recycled materials and process efficiencies. Unlike virgin ores, which often require extensive refinement to eliminate impurities, recycled materials are sourced from standardized manufactured batteries, minimizing impurities and variability in metal composition. Additionally, recycled CAM precursors maintain favorable crystal structures and grain morphology, facilitating the production of CAM with enhanced electrochemical properties.

Altilium is advancing the next generation of sustainable battery raw materials at its UK facilities and is collaborating with the UK Battery Industrialisation Centre (UKBIC) to produce battery cells using its recycled CAM for validation with a leading automotive OEM. By demonstrating that recycled materials can be both cost-effective and higher quality than virgin materials, while also offering lower carbon emissions, Altilium is promoting a “Green Value Proposition” that supports the transition to electric vehicles.

Source: Altilium Tech