The Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University, in collaboration with leading research and industry partners, has initiated the three-year “SchnelleZelle” project to enhance the fast-charging capabilities of prismatic lithium-ion batteries. Funded by the Federal Ministry for Economic Affairs and Climate Action, the project aims to decrease charging times and increase charging power while maintaining battery safety and longevity.

Professor Achim Kampker, Director of PEM, emphasized the significance of improving fast-charging technology in lithium-ion batteries, noting its importance to both research and industry sectors. Professor Heiner Heimes, a member of PEM’s management team, added that advancements would be achieved through the integration of sensors within the cells and innovative strategies in cell design, cooling, and charging algorithms.

The project adopts a comprehensive approach, covering all stages from initial development to cell integration. This strategy is expected to lead to significant innovations in various aspects, including cell design, electrode interconnection, sensor integration, and the development of enhanced cooling and control mechanisms. The initiative targets a several percent increase in the charging rate within the state of charge (SOC) range of ten to eighty percent, utilizing a model-based approach to facilitate immediate design evaluations.

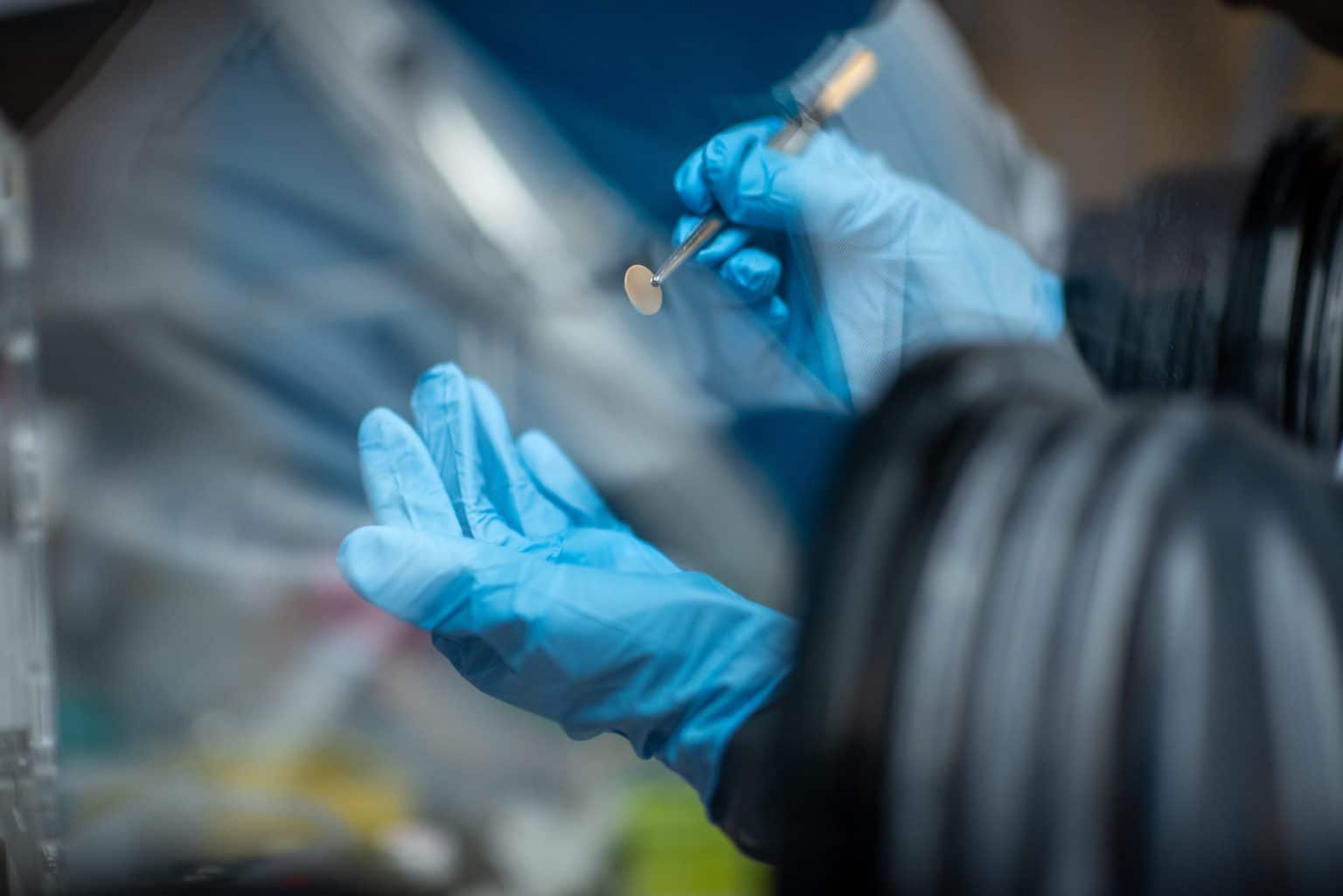

A key component of the project involves embedding location-resolving sensors into battery cells and employing machine learning algorithms to optimize and adapt charging processes based on individual battery conditions. Additionally, efforts will focus on reducing internal resistance and enhancing thermal stability by optimizing the connection between the electrode stack and the cell housing. The anticipated outcomes will be developed into prototypes, which will include both individual cells and cell networks, and will undergo suitability testing for potential application in the battery industry.

The project consortium includes prominent partners such as the Fraunhofer Research Institution for Battery Cell Production (FFB), the Institute for Power Electronics and Electrical Drives (ISEA) at RWTH Aachen University, MAHLE Behr GmbH & Co. KG, HOERBIGER Antriebstechnik Holding GmbH, FLEXOO GmbH, and TRUMPF Laser- und Systemtechnik GmbH as an associated partner.

Source: RWTH Aachen University