Samsung SDI is advancing its production of lithium iron phosphate (LFP) batteries for energy storage systems (ESS), aiming to begin mass production by late this year. This move targets the U.S. market, where Samsung SDI anticipates a reduction in Chinese competition.

An industry source revealed that the company plans to finalize the setup of production equipment for ESS LFP batteries at its Ulsan plant’s “mother line” between July and August. Should the new LFP production prove successful, Samsung SDI may accelerate large-scale manufacturing to the end of 2025, ahead of the initially planned 2026 timeline.

The “mother line” is an advanced pilot production line designed to develop and test new manufacturing processes on a smaller scale before moving to commercial production. Unlike traditional pilot lines, which operate on a laboratory scale, the mother line evaluates the feasibility of efficiently scaling up production.

Currently, Samsung SDI’s Ulsan plant specializes in producing nickel, cobalt, and manganese (NCM) batteries for ESS, which are more expensive than LFP cells. The LFP segment has long been dominated by Chinese battery manufacturers. In response to slowing electric vehicle (EV) sales, Samsung SDI is realigning its production lines to prioritize batteries with strong demand, such as those for ESS, to maintain factory utilization rates. North America is a key target market for this initiative. Samsung SDI aims to compete directly with Chinese rivals by offering LFP batteries that provide higher capacity at comparable prices.

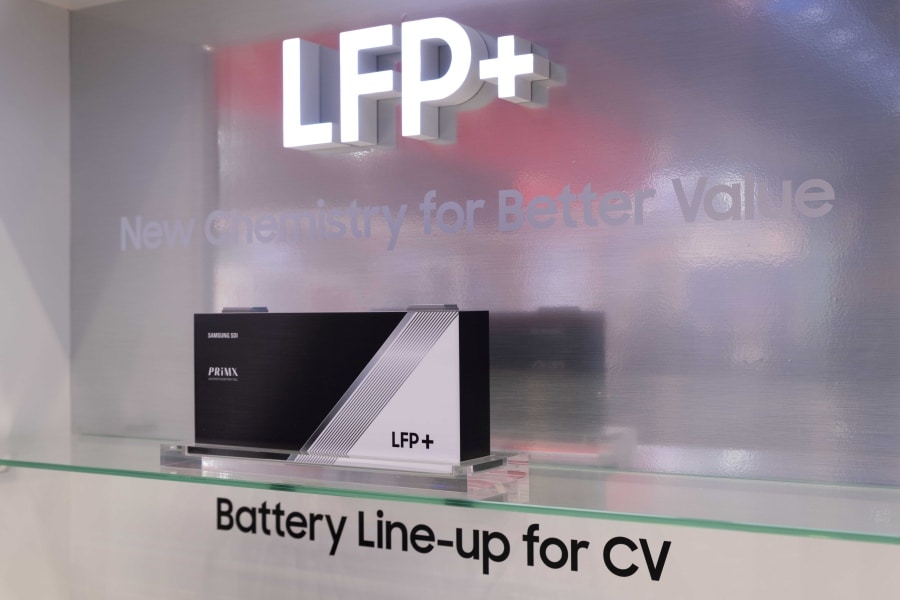

Last year, Samsung SDI demonstrated its commitment by unveiling an LFP battery prototype for ESS in Seoul, named “LFP+.” This product features enhanced chemistry for superior performance, setting a higher industry standard.

The LFP cells produced at the Ulsan plant will be shipped to Samsung SDI’s battery pack facility in Michigan, where they will be supplied to grid operators and other customers across North America. Last year, the Michigan plant’s electric bike battery pack line was converted for ESS production. Unlike LG Energy Solution and SK On, which operate battery cell manufacturing plants in the U.S., Samsung SDI assembles battery packs in Michigan using cells produced in South Korea and Hungary.

Samsung SDI’s increased production capacity could help narrow its nearly year-long gap with LG Energy Solution, which plans to begin full-scale ESS LFP battery production this year after retooling its Michigan facility. SK On is also preparing to produce LFP battery cells for ESS in North America as soon as this year.

Chinese companies currently dominate the global ESS market, holding an 85 percent share in 2023. In contrast, Samsung SDI and LG Energy Solution accounted for 5 percent and 4 percent, respectively, a significant decrease from their combined 55 percent market share in 2020.

Source: The Korea Herald