Key Players in Silicon battery Development & Manufacturing

NEO Battery Materials

NEO Battery Materials Ltd., based in Vancouver and listed on TSXV and OTC, advances silicon anode technology for lithium-ion batteries. Their proprietary NBMSiDE® nanocoating boosts energy density and battery longevity, targeting electric vehicles, electronics, and energy storage applications.

Ionic Mineral Technologies

Ionic Mineral Technologies of Utah develops Ionisil™, an advanced nano-silicon anode for lithium-ion batteries. Their vertically integrated approach, using proprietary halloysite reserves, boosts battery capacity and charging speeds, supporting the growing electric vehicle market sustainably.

3DBattery

Founded in 2017 in Rehovot, Israel, 3DBattery develops advanced lithium-ion energy storage solutions featuring silicon-based anodes and safer, liquid-free designs. Their innovative batteries enhance performance for electric vehicles, grid storage, and consumer electronics, supported by plans for a green gigafactory by 2024.

Advanced Cell Engineering

Established in 2022 in Stuart, Florida, Advanced Cell Engineering (ACE) develops next-generation lithium-ion batteries for electric vehicles and grid storage. Led by industry experts CEO John Kaufman and COO Masayuki Yasuda, ACE’s proprietary A-LFP™ and LFP SiOx™ technologies deliver enhanced energy density, safety, and cost-effectiveness, compatible with existing manufacturing systems.

ADVANO

Founded in 2016 and based in New Orleans, ADVANO specializes in silicon-based anodes for lithium-ion batteries. Their proprietary REALSi™ technology boosts energy density, performance, and cost-efficiency, enabling advancements in electric vehicles, consumer electronics, and energy storage systems.

ALKEGEN

Alkegen, formed by Unifrax and Lydall Materials, is a global leader in high-performance specialty materials with over 60 facilities and 9,000 employees. They innovate in battery technology, insulation, filtration, and more, focusing on energy efficiency, safety, and sustainability.

Altech Batteries

Altech Batteries Ltd, an Australian firm, pioneers innovative battery solutions for grid storage and lithium-ion markets. Its CERENERGY® and Silumina Anodes™ technologies offer enhanced safety, durability, and efficiency.

American Lithium Energy (ALE)

American Lithium Energy (ALE), based in Carlsbad, CA, leads in silicon-anode lithium-ion batteries, offering high energy density and safety for electric vehicles, defense, aerospace, and more. With 40 patents and over a decade supplying the DoD and DOE, ALE drives sustainable energy solutions through innovative technology and strategic partnerships.

Ampcera Inc.

Ampcera Inc., founded in 2017 and based in Milpitas, CA, specializes in solid-state battery materials and integrated systems. Utilizing advanced sulfide-based electrolytes, they produce high-energy, safe batteries with up to 400 Wh/kg and rapid charging. Serving over 200 global clients, Ampcera is expanding production to meet growing demand by 2026.

Amprius Technologies Inc.

Amprius Technologies Inc., founded in 2008 and based in Fremont, California, is a leading manufacturer of high-energy lithium-ion batteries using advanced silicon nanowire anode technology. Achieving up to 500 Wh/kg, Amprius serves electric vehicles, aviation, and portable electronics sectors. Listed on the NYSE as AMPX since 2022, the company is expanding its manufacturing to meet growing demand.

Arkema

Arkema, a global leader in specialty materials based in France, operates in over 55 countries. Committed to innovation and sustainability, it develops high-performance adhesives, coatings, and advanced materials for industries like automotive and renewable energy. In battery technology, Arkema enhances lithium-ion and next-generation batteries with advanced, sustainable solutions.

Beyonder

Beyonder AS, established in 2016 in Sandnes, Norway, develops sustainable high-capacity battery solutions using proprietary Lithium-Ion Capacitor technology. Their eco-friendly, efficient batteries support renewable energy, maritime transport, and electric infrastructure, driving the global green transition.

Blue Current Inc.

Blue Current Inc., based in Hayward, California, develops advanced all-solid-state batteries using silicon elastic composite technology. Their safer, high-energy solutions target electric vehicles, wearables, and mobility applications, aiming to enhance efficiency, reduce costs, and ensure reliable energy storage.

BTR New Material Group Co. Ltd

BTR New Material Group Co., Ltd., China’s largest lithium-ion battery materials manufacturer, specializes in advanced cathode and anode components. Serving global EV and battery leaders, BTR emphasizes research and development and has expanded production to Morocco and Indonesia.

CELLARK POWERTECH

Cellark Powertech advances lithium-ion storage with breakthrough Porosil silicon anodes. Developed in India, its process boosts energy density by up to 30% and reduces anode use by over 50%, driving efficiency in battery applications.

CELLFORCE Group

Cellforce Group GmbH, a Porsche AG subsidiary in Tübingen, Germany, specializes in high-performance lithium-ion battery cells for electric vehicles. Focusing on enhanced energy density, fast-charging, and sustainable production, the company leverages advanced silicon-based technology for next-generation automotive battery solutions.

Cenate AS

Cenate AS, a Norwegian leader in silicon-based anode materials for lithium-ion batteries, develops nano-structured silicon that boosts energy density by up to 30% and reduces CO₂ emissions by over 93%. Their technology integrates seamlessly into existing manufacturing, enhancing batteries for electric vehicles, electronics, and more.

Coreshell

Coreshell Technologies, based in San Leandro, CA, develops advanced battery solutions for electric vehicles and renewable energy. Specializing in high-performance silicon anodes and proprietary nanolayer coatings, Coreshell enhances battery capacity, reduces costs, and improves sustainability, facilitating broader EV adoption.

Daejoo Electronic Materials

Daejoo Electronic Materials, established in 1981, specializes in advanced battery and electronic materials. As South Korea’s sole mass-producer of silicon anodes, it drives innovation across EV, IT, and industrial applications.

E-Magy

Founded in 2013 in the Netherlands, E-Magy pioneers nano-porous silicon anode technology that boosts lithium-ion battery energy density by up to 40% and enables faster charging while integrating seamlessly with existing lines.

Enevate Corporation

Enevate Corporation, based in Irvine, California, specializes in advanced lithium-ion silicon-dominant anode technology for electric vehicles. Founded in 2005, Enevate’s innovations enable ultrafast charging, increased range, and improved battery performance, partnering with major automotive and battery manufacturers to drive EV adoption.

ENOVIX Corporation

Enovix Corporation, based in Fremont, CA, develops high-energy-density silicon-anode lithium-ion batteries using proprietary 3D cell architecture. Serving consumer electronics and wearables, they target applications in electric vehicles and energy storage. Publicly traded on Nasdaq (ENVX) since 2021.

Focus Graphite

Focus Graphite Inc. (TSXV: FMS) is a Canadian mining and exploration company based in Kingston, Ontario. Specializing in high-grade flake graphite for lithium-ion batteries, their Quebec projects leverage advanced, eco-friendly processing technologies to support the electric vehicle and renewable energy industries.

Forge Nano Inc.

Forge Nano Inc., based in Thornton, Colorado, specializes in Atomic Layer Deposition with its proprietary Atomic Armor platform. Founded in 2011, it enhances materials for batteries, semiconductors, and pharmaceuticals, driving efficiency and sustainability through precision nano-coating technologies.

GDI

GDI is a global leader in battery technology, specializing in 100% silicon anodes for lithium-ion batteries. Their innovative solutions enhance energy density and charging speed, catering to sectors like electric vehicles and aerospace. Supported by major investments, GDI aims for large-scale production by 2028.

Gelion

Gelion plc, headquartered in London and listed on AIM, pioneers lithium-sulfur and zinc-bromide energy storage solutions. Originating from the University of Sydney, the company delivers sustainable technologies for renewable energy, aerospace, and automotive applications, supported by strategic partnerships and robust investments.

Group14 Technologies

Established in 2015 in Woodinville, Washington, Group14 Technologies manufactures advanced silicon-carbon composite SCC55™, enhancing lithium-ion batteries with 50% longer life and faster charging. Their innovative technology supports electric vehicles, consumer electronics, and aviation applications, backed by major investors and global expansion.

HKG Energy

HKG Energy elevates lithium-ion batteries through advanced silicon anode materials that boost energy density, speed charging, and extend cycle life. Their technology enhances EVs, consumer devices, and renewable storage.

HPQ Silicon Inc.

HPQ Silicon Inc., headquartered in Montréal, leverages PUREVAP™ technology to produce high-purity silicon and silica for sustainable applications. Its advanced materials boost EV battery performance and support low-carbon energy systems.

Ilika

Ilika plc, founded in 2004 in the UK, leads in solid-state battery technology with operations in the UK, USA, and Japan. It develops safer, more efficient batteries for electric vehicles, medical devices, and IoT applications, advancing energy storage in transportation and healthcare sectors.

InoBat

InoBat, founded in 2019 in Bratislava, Slovakia, is a European battery technology company specializing in customized lithium-ion solutions for automotive, commercial, motorsport, and aerospace industries. Leveraging advanced nickel-rich chemistries and silicon-based anodes, InoBat delivers high energy density, safety, and tailored performance through its state-of-the-art manufacturing facilities.

Ionblox

Ionblox Inc., founded in 2017 and based in Fremont, CA, develops advanced silicon-based lithium-ion batteries for electric vehicles and eVTOL aircraft. Their innovative technology enables rapid charging, extended range, and prolonged battery life, supporting the growth of electric mobility.

ionobell

Ionobell, a San Jose-based battery technology company, pioneers next-generation silicon-dominant battery solutions with porous nano-silicon anodes delivering up to 50% greater energy density than traditional cells. Its scalable platform enables cost-effective upgrades in automotive and consumer electronics sectors.

JR Energy Solution

Established in December 2022, South Korea-based JR Energy Solution specializes in high-performance lithium-ion battery electrodes using advanced silicon-dominant technology. Serving startups and established manufacturers, they support rapid development and fast-charging applications for electric vehicles.

Leading Edge Materials Corp.

Vancouver-based Leading Edge Materials Corp. advances EU critical raw materials for clean energy technologies. Through projects like the Woxna Graphite mine and advanced ALD-coated battery anodes, they provide sustainable materials essential for lithium-ion batteries, electric motors, and wind power systems.

LeydenJar

LeydenJar, founded in 2016 in the Netherlands, develops advanced pure silicon anodes for lithium-ion batteries, boosting energy density by 70% and cutting CO₂ emissions by 85%. Their technology enhances batteries for electric vehicles, electronics, and more, promoting sustainable energy storage solutions.

NanoGraf Corporation

NanoGraf Corporation, based in Chicago since 2012, develops advanced silicon-graphene anode materials for lithium-ion batteries, increasing energy density by up to 50%. Their innovative technology supports electric vehicles, consumer electronics, and military applications, strengthening the U.S. battery supply chain.

Nexeon Ltd

Nexeon Ltd, founded in 2006 as an Imperial College London spin-off, is a global leader in silicon anode materials for lithium-ion batteries. Their NSP2™ technology boosts energy density by up to 50%, enabling smaller, more efficient batteries for electric vehicles, electronics, and medical devices.

NorcSi GmbH

NorcSi GmbH, founded in 2020 in Halle, Germany, specializes in high-performance silicon anodes for lithium-ion batteries. Their patented technology enhances energy density and charging speed, applicable to electric vehicles, electronics, and more, supported by advanced manufacturing capabilities.

Novacium SAS

Novacium SAS, founded in 2022 in Solaize, France, is a materials science startup advancing silicon-based anode technology for high-performance lithium-ion batteries and innovative hydrogen production through recycling improvements.

OneD Battery Sciences

OneD Battery Sciences, founded in 2013 in Palo Alto, develops advanced silicon nanowire-based SINANODE technology for electric vehicle batteries. Their innovations enhance energy density, accelerate charging, and lower costs, positioning OneD as a key player in advancing EV battery performance and adoption.

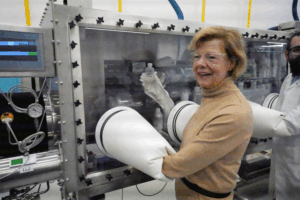

Panasonic Energy of North America

Panasonic Energy of North America (PENA), based in Newark, NJ, is a leading lithium-ion battery manufacturer at Tesla’s Nevada Gigafactory. Since 2017, PENA has produced over six billion cells for electric vehicles, specializing in cylindrical formats like 2170 and the upcoming 4680, and partners with major automakers to advance sustainable energy solutions.

Paraclete Energy

Paraclete Energy, based in Chelsea, Michigan, develops advanced SILO Silicon™ anode materials for lithium-ion batteries, enhancing electric vehicle performance with higher energy density and faster charging. Partnering with major automakers, they drive innovation in EV battery technology.

Samsung SDI

Samsung SDI, founded in 1970, is a global leader in advanced battery technologies and electronic materials. Specializing in lithium-ion and solid-state batteries, it serves electric vehicles, consumer electronics, and energy storage systems, driving innovation and sustainable energy solutions worldwide.

Sicona Battery Technologies

Sicona Battery Technologies, based in Australia, develops advanced silicon-carbon anode materials using proprietary SiCx® technology. Their innovations enhance lithium-ion battery energy density and charging performance for electric vehicles and energy storage, supporting the global transition to electrification.

Sienza Energy

Sienza Energy, based in El Segundo, California, develops advanced 100% silicon anode batteries with over 1000 Wh/L energy density and rapid charging. Founded in 2017, the company’s sustainable technology enhances performance for electric vehicles, consumer electronics, and energy storage applications.

Sila Nanotechnologies

Sila Nanotechnologies Inc., founded in 2011 in California, enhances lithium-ion batteries with its Titan Silicon anode material. Offering higher energy density and faster charging, Sila’s technology improves electric vehicles and electronics. Partnering with industry leaders, the company has raised over $1.4 B to scale production.

SiLi-ion Inc.

SiLi-ion Inc. pioneers advanced lithium-ion battery technology with its innovative silicon-carbon additive, which leverages silicon nanoparticles and recycled materials to enhance energy density and charging speed efficiently.

Sino Applied Technology (SiAT)

Sino Applied Technology (SiAT), founded in 2018 in Taoyuan City, Taiwan, specializes in advanced nano-materials for lithium-ion batteries. Their innovative nano silicon anodes and SWCNT conductive pastes enhance battery efficiency and longevity, supporting renewable energy adoption.

Sinova Global

Sinova Global, based in Canada, produces high-purity silicon metal crucial for clean energy. Its integrated process—from quartz mining to metal refinement—drives innovations in solar panels, semiconductors, and EV battery systems.

Sionic Energy

Sionic Energy, based in Rochester, NY, develops next-generation lithium-ion batteries with silicon anodes and advanced electrolytes. Offering 50% higher energy density and 30% lower costs, their scalable technology serves automotive, consumer electronics, and aviation industries.

Solidion Technology Inc.

Solidion Technology Inc., based in Dallas, specializes in advanced battery technologies for electric vehicles and renewable energy. Holding over 500 patents, the company leads in silicon anodes, nanostructured graphene-sulfur cathode, sustainable graphite production, and graphene-enhanced fast-charging solutions.

StoreDot

StoreDot, founded in 2012 in Israel, develops silicon-based extreme-fast charging (XFC) batteries for electric vehicles. Their innovative technology enables EVs to charge in under 10 minutes, advancing sustainable mobility with support from leading automakers and major investors.

Talga Group

Talga Group, based in West Perth, Australia, specializes in sustainable battery anode and advanced materials for electric vehicles and consumer products. From high-grade graphite mining to finished anodes, Talga develops solutions like Talnode®-C and Talnode®-Si, enhancing lithium-ion battery performance and supporting global sustainability.

Tesla

Founded in 2003 and led by Elon Musk, Tesla is a leading American multinational specializing in electric vehicles, battery storage, and solar energy. Utilizing advanced technologies like 4680 batteries and a direct-to-consumer model, Tesla drives innovation and sustainability in the clean energy sector.

The Coretec Group Inc.

Based in Ann Arbor, The Coretec Group Inc. specializes in silicon-based energy storage and materials science. Utilizing proprietary Cyclohexasilane technology and the Endurion battery program, they develop advanced silicon anodes for lithium-ion batteries used in electric vehicles and renewable energy systems.

TRION Battery

TRION Battery Technologies Inc., based in Calgary, develops advanced lithium-ion and silicon-based batteries for electric vehicles and industrial uses. Their innovative SX-Silicon and LFP technologies enhance capacity and lifespan, driving the clean energy transition.

VoltaXplore

VoltaXplore, a Montreal-based Canadian company founded in 2021, manufactures advanced 21700 lithium-ion battery cells for electric vehicles and grid applications. Utilizing silicon anode materials and nanotechnology, they achieve high capacity and rapid charging. Their 1 MWh facility supports sectors like transportation and military, while developing solid-state batteries for future growth.

Silicon Battery Technology

Silicon battery technology uses silicon—often as part of the anode or within composite materials—to store more electrical energy than traditional lithium-ion designs that rely on graphite. The technology has attracted interest across consumer electronics, electric vehicles, and storage systems because it can provide longer-lasting power and faster charging without significant modifications to current battery assembly processes. Researchers and manufacturers continue to work on the technical issues that prevent silicon batteries from becoming a mainstay in high-performance energy solutions.

Key Characteristics of Silicon Battery Technology

Enhanced Energy Capacity

Silicon offers a much higher lithium storage capacity than graphite. This increase in capacity means that batteries built with silicon can hold more energy per unit of volume, which translates into extended operating times for portable devices and greater driving range for electric vehicles.

Fast Charging

Better reaction kinetics in silicon-based batteries can support shorter charging cycles. This improvement is particularly valuable in applications where time is critical, such as in transportation and consumer electronics.

Compact and Lightweight Design

Because silicon batteries can achieve high energy density within a smaller volume, devices can be made lighter and more compact. This attribute is important for portable gadgets and vehicles where reducing weight can significantly affect overall performance and energy efficiency.

Technology Classifications / Types

Silicon battery technology includes several types based on how silicon is integrated into the cell design:

Nanostructured Silicon

Technologies have been developed to use silicon nanowires or nanoparticles, which are designed to handle the expansion that occurs during charging. By reducing the particle size, manufacturers can maintain battery integrity over many cycles.

Composite Anodes

Combining silicon with carbon or polymeric materials provides a more stable structure. These composites manage the stress caused by silicon’s swelling while still offering enhanced storage capacity.

Advanced Electrode Architectures

Innovative configurations such as three-dimensional porous structures and multilayer electrodes contribute to improved ion transport. These designs help to facilitate quicker charging and better overall performance, even under repeated cycling.

Development and Commercialization Challenges

Volume Expansion

Silicon can expand by up to 300% during the insertion of lithium ions. This large change in volume can damage the electrode and result in a rapid decay in capacity. To address this, researchers are focusing on using nanostructures and protective coatings to absorb or mitigate the strain.

Stability Over Multiple Cycles

Maintaining consistent performance over numerous charge/discharge cycles remains a technical hurdle. Efforts include optimizing binder materials and electrode designs to preserve structural integrity during use.

Manufacturing Processes

Transitioning from research to cost-effective production means developing methods that can be adopted on an industrial scale. Manufacturers are working to integrate silicon into existing battery production lines while controlling costs and ensuring uniform performance.

Recent Developments and Examples

Several companies have made visible progress in silicon battery technology:

Ionic Mineral Technology

Ionic MT has secured the Silicon Ridge halloysite property from the State of Utah, in a move to expand its nano-silicon anode battery material production. This strategic acquisition will increase the companies halloysite reserves, which are critical for meeting the growing demand for fast-charging EV and energy storage market.

Sila Nanotechnologies

Sila Nanotechnologies has developed Titan Silicon™ nano-composite anodes designed to replace graphite in existing battery systems. Their approach supports current production processes and has led to partnerships with automotive and electronics companies, including collaborations with Mercedes and Panasonic.

Group14 Technologies

Group14 Technologies introduced the SCC55® silicon–carbon composite material. By embedding silicon within a carbon matrix to control volume changes, the technology has found support from original equipment manufacturers such as Porsche.

Amprius Technologies

Amprius Technologies has achieved energy density figures as high as 500 Wh/kg through the use of silicon nanowire-based anodes. Their batteries are being tested for use in both aerospace and electric vehicles, supported by research organizations and automotive collaborators.

Enovix Corporation

Enovix Corporation uses an innovative three-dimensional cell design that incorporates 100% active silicon anode material. Their technology aims to offer improved storage capacity and efficiency for consumer electronics and electric vehicle applications.

LeydenJar Technologies

LeydenJar Technologies has addressed silicon swelling by building a porous, 100% silicon anode. Their design maintains performance over a long number of cycles and is already under evaluation by major manufacturers.

In addition to these business entities, more players such as Enevate Corporation, Nexeon (UK), and NEO Battery Materials are addressing challenges like fast charging and capacity retention. Meanwhile, manufacturing groups in Asia, including BTR New Material Group and Shanshan Technology, support large-scale production by producing silicon–carbon composite anodes for companies in the automotive and electronics sectors.

This overview provides insight into the technical potential of silicon battery technology, along with the hurdles that must be overcome to bring these energy solutions to widespread commercial use.