SK On, a leading South Korean battery cell manufacturer, has announced a strategic partnership with Sakuu, an innovative California-based developer specializing in 3D printed solid-state batteries. The collaboration aims to advance the industrialization of Sakuu’s Kavian platform, a cutting-edge technology that revolutionizes the production of battery electrodes through a dry printing process.

Sakuu has successfully manufactured high-performance Li-Metal batteries using a fully dry process, achieving significant milestones in energy density and cycle life while improving manufacturing efficiency and sustainability. This technology eliminates the need for solvents, resulting in lower cost, higher performance and more environmentally friendly batteries.

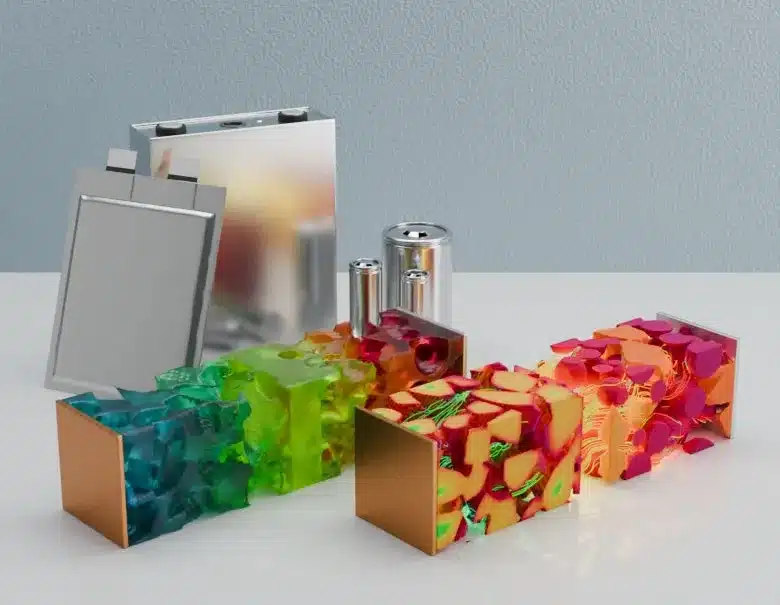

By combining different additive manufacturing techniques, the Kavian platform enables the use of different materials, including ceramics, metals and a proprietary substrate called PoraLyte, which simplifies the 3D printing of complex components. The partnership is expected to improve the safety, sustainability, and innovation of battery technology, addressing key industry challenges.

The Cypress battery cell has achieved notable performance metrics:

- 1,000 cycles at 100% DoD to 80% SOH @ 0.3C/1C

- 800+ Wh/L Volumetric Energy Density of active cell area

- 3C Sustained Discharge, 10C Peak, with full recovery

- 8C Pulse Discharge

Dry printing on the Kavian platform offers several advantages:

- Eliminates toxic solvents and materials

- Reduces factory floor space by up to 33%

- Reduces utility costs by up to 40%

- Improves factory carbon footprint by up to 40%

Founded in 2016, Sakuu aims to achieve an annual production capacity of 200 GWh for lithium metal and solid-state batteries by 2030, with support from Porsche Consulting in planning its gigafactories. Currently, Sakuu operates a pilot line for solid-state batteries and an engineering center in Silicon Valley, demonstrating significant progress in 3D printing fully functional, high-performance batteries.

Source: Electrive, Sakuu Newsroom