The initiative comes in response to the EU Battery Regulation, which took effect in August 2023. This regulation requires manufacturers to declare carbon footprints and prioritize environmental considerations throughout the product life cycle, prompting companies worldwide to enhance the sustainability of their battery technologies.

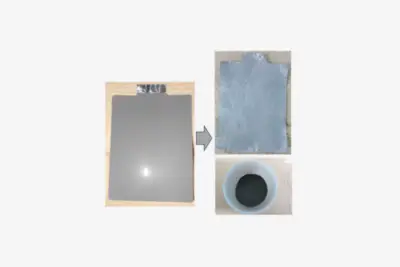

Toshiba’s new method leverages the stable crystal structures of oxide active materials. By employing direct recycling, active materials are reused without reverting to their base chemical elements. The stability of these materials allows for their separation from the negative electrode’s current collecting foil through simple heat treatment, eliminating the need for complex reactivation processes and reducing costs.

The company successfully applied this method to its niobium-titanium oxide anode batteries. Performance evaluations showed that batteries made with recycled electrodes retained more than 97% of their capacity, comparable to new electrodes. According to Toshiba, the recycled batteries also exhibited the same long life as new ones.

This development marks Toshiba’s first major venture into battery recycling. Previously, the company has been active in various areas of battery production and recently entered the battery swapping market. In October, Toshiba announced a design collaboration with Airbus on superconducting engines for hydrogen aircraft, further expanding its involvement in sustainable energy solutions.

Source: Electrive