tozero, a prominent European startup specializing in sustainable lithium-ion battery recycling, announced on February 13, 2025, that it has successfully produced battery-grade recycled graphite at an industrial scale. This marks the first instance where 100% recycled anode material has been utilized in battery cell production, demonstrating its viability for commercial use.

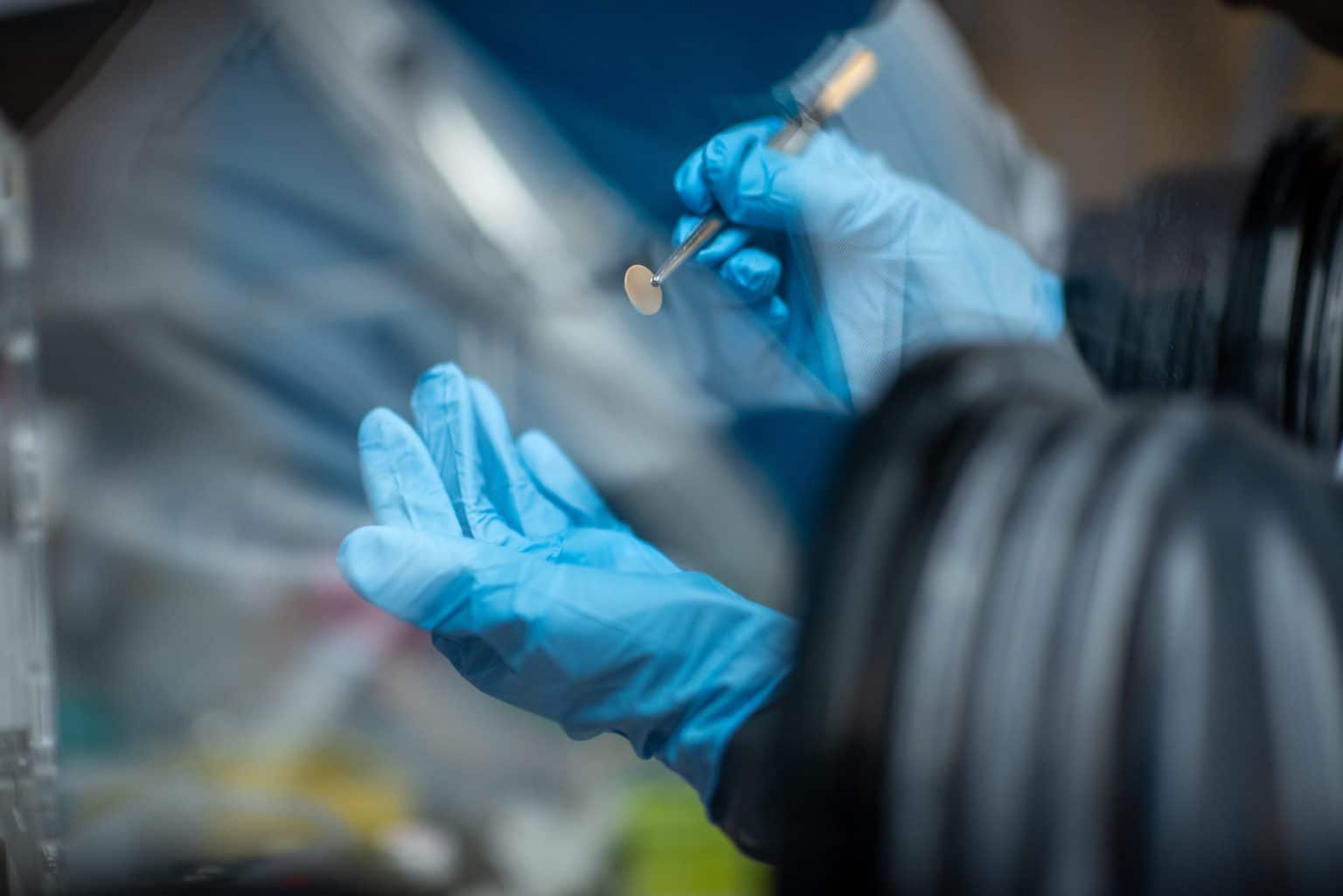

Traditional recycling methods often result in graphite being incinerated or lost to waste streams due to the use of strong acids, which hinders efficient recovery. In contrast, tozero’s innovative process achieves over 80% graphite recovery while maintaining its morphological integrity on an industrial scale. The recovered graphite can be refined to meet battery-grade quality standards, offering performance comparable to that of battery cells made from virgin graphite.

This advancement underscores the potential for integrating recycled graphite into global supply chains, which can significantly reduce carbon emissions, accelerate the transition to electric mobility, and promote the circularity of battery materials. The achievement was made possible through dedicated efforts and collaborations, highlighting the feasibility of using recycled materials within the battery industry.

Sarah Fleischer, Co-founder and CEO of tozero, commented on the milestone: “This is a milestone not just for tozero, but for Europe’s battery industry as a whole. We’ve already seen our recycled lithium successfully re-enter Europe’s supply chain, and now we’re proving the same for graphite. Despite being essential for battery stability, graphite is often overlooked in recycling—largely seen as unrecoverable—yet it is even more critical and geopolitically exposed than lithium. Our FOAK plant is on track, and we’re scaling to recover even more critical materials, helping companies worldwide decarbonize, secure local supply chains, and move towards true circularity—bringing lithium-ion battery waste to zero.”

Battery and automotive manufacturers are increasingly adopting recycled graphite to enhance supply chain resilience and comply with regulations such as the EU Battery Directive and the European Critical Raw Material Act. Scaling the production of high-quality, battery-grade recycled graphite is essential for reducing dependency on imports, lowering emissions, and ensuring a stable, circular supply chain to support the future of clean energy.

Founded in 2022, tozero is addressing Europe’s recycled battery supply gap by providing local resources to ensure a stable supply for various industries. The company’s breakthrough process is highly efficient, consumes low energy, and employs environmentally friendly recovery methods without using strong acids. By 2027, tozero aims to produce over 2,000 tonnes of recycled graphite, with plans to scale beyond 10,000 tonnes by 2030. To date, the company has secured €17 million in funding from investors including NordicNinja, Atlantic Labs, Honda, and JGC Group, highlighting its potential to expand sustainable battery recycling on a global scale.

Source: tozero