Vianode, an advanced battery materials company, and Fortum Battery Recycling, a specialist in reclaiming valuable metals from electric vehicle (EV) batteries, have entered into a Memorandum of Understanding aimed at developing a sustainable EV battery recycling value chain. Announced in Oslo, Norway, on May 13, 2025, the collaboration seeks to enhance the recycling and utilization of graphite, a critical component in lithium-ion batteries.

Under the agreement, Vianode and Fortum Battery Recycling will collaborate to secure high-quality recycled graphite concentrate from Fortum’s hydrometallurgical facility in Harjavalta, Finland. The partnership will focus on developing and optimizing recycled graphite materials for Vianode’s commercial-scale anode production. Additionally, the companies will work together to evaluate and improve the performance of recycled graphite in advanced battery components.

“Recycling graphite from end-of-life batteries is vital to reduce dependence on virgin raw materials, lower carbon emissions, and build sustainable supply chains. Access to recycled graphite concentrate with potential to scale volumes over time will support Vianode’s ambition to deliver high-quality anode materials with an industry-leading CO₂ footprint below 1 kilogram CO₂e per kilogram of graphite by 2030”, says Dr. Stefan Bergold, Chief Commercial Officer of Vianode.

Graphite anode material constitutes approximately 70% of the weight of lithium-ion batteries used in EVs. By incorporating recycled graphite into its production processes, Vianode aims to advance the development of low-carbon, high-performance battery materials. This initiative aligns with Europe’s projected increase in battery recycling by 2030, driven by the aging EV fleet and new EU regulations mandating higher recovery rates and the use of recycled materials in new batteries.

“Fortum Battery Recycling and Vianode have a shared commitment to a more sustainable and less resource-intensive EV battery industry. By recovering valuable and critical graphite from used batteries and returning it to the cycle as battery-grade material, we help enable the production of new lithium-ion batteries with a significantly lower environmental footprint,” says Tero Holländer, Head of Business Line, Batteries, Fortum Recycling & Waste.

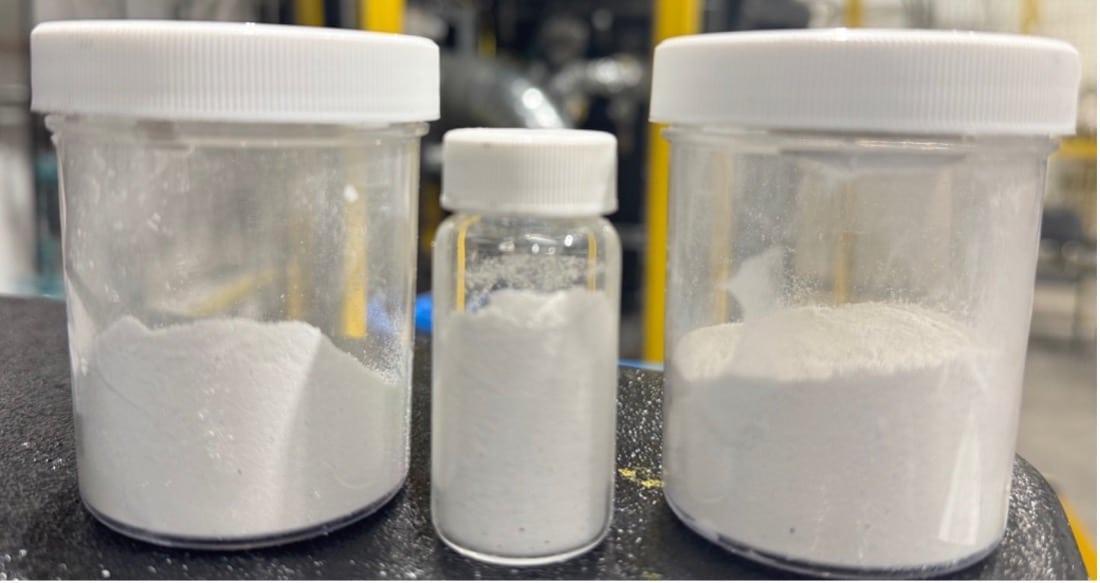

Vianode recently introduced its first high-performance anode material derived from recycled battery-grade graphite, reinforcing the company’s strategy to establish a circular battery value chain in North America and Europe. The collaboration with Fortum Battery Recycling supports Vianode’s long-term goal of supplying advanced battery materials to three million EVs annually by 2030.

Source: Vianode