In January 2025, Vianode, a company specializing in advanced battery materials, announced it has been chosen as a strategic supplier of high-performance synthetic anode graphite for General Motors. The agreement, valued at several billion USD, includes the development of large-scale manufacturing capacity and the supply of synthetic anode graphite through 2033. This partnership signifies a significant advancement in bolstering the North American battery and electric vehicle (EV) supply chain.

Production of the high-performance anode graphite is set to commence in 2027 at Vianode’s large-scale plant in North America, which complies with the Inflation Reduction Act (IRA). The agreement, featuring a minimum off-take commitment, follows a multi-year qualification process. This process confirmed that the anode graphite produced at Vianode’s pilot plant in Norway meets stringent performance and validation criteria.

The synthetic graphite will be utilized by Ultium Cells LLC, GM’s battery cell manufacturing joint venture with LG Energy Solution, for next-generation EV batteries and drive units. The agreement also allows for the possibility of extending deliveries to include other joint ventures.

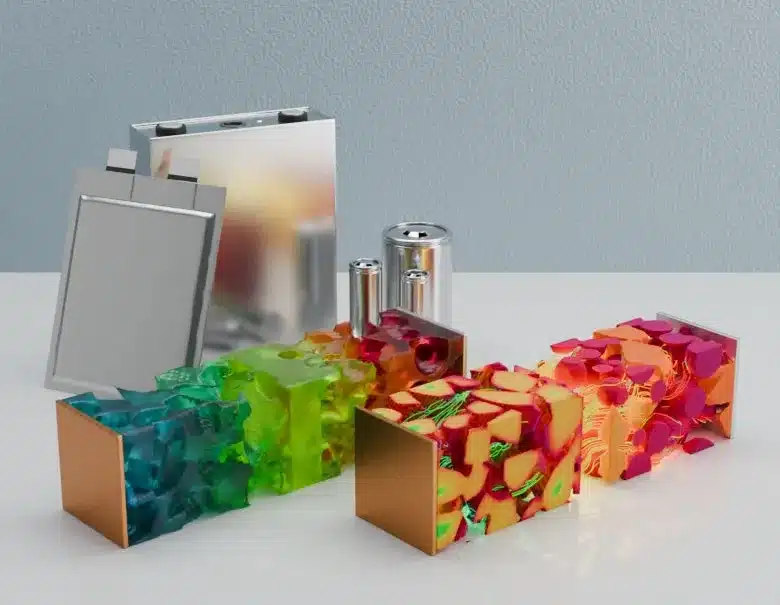

Anode graphite is the largest component by weight in a lithium-ion battery and plays a critical role in the transition to sustainable energy. Vianode’s synthetic anode graphite has a 90% lower CO2 footprint compared to conventional production methods. Unlike natural graphite, which is mined from carbon-rich rock formations, synthetic graphite is produced through high-temperature manufacturing processes.

Vianode is preparing to initiate a phased, multi-billion-dollar investment program to develop large-scale sustainable anode graphite production facilities in North America and Europe. The company aims to supply advanced materials sufficient for 3 million EVs annually by 2030, establishing itself as a leading provider of advanced anode graphite solutions.

Burkhard Straube, CEO of Vianode, emphasized the importance of the agreement, stating that it is a key step in creating a resilient and localized supply chain for critical battery materials outside of Asia. Jeff Morrison, Senior Vice President of Global Purchasing and Supply Chain at General Motors, highlighted the collaboration as part of GM’s strategic efforts to build a sustainable battery supply chain in North America, which will enhance battery technology and deliver greater value to customers.

Since 2021, Vianode has been producing anode graphite solutions at its industrial pilot facility in Kristiansand, Norway. The company opened its Technology Center in the same city in 2022, and commenced operations at its first full-scale production plant in Herøya, Norway, in the latter half of 2024.

Source: Vianode