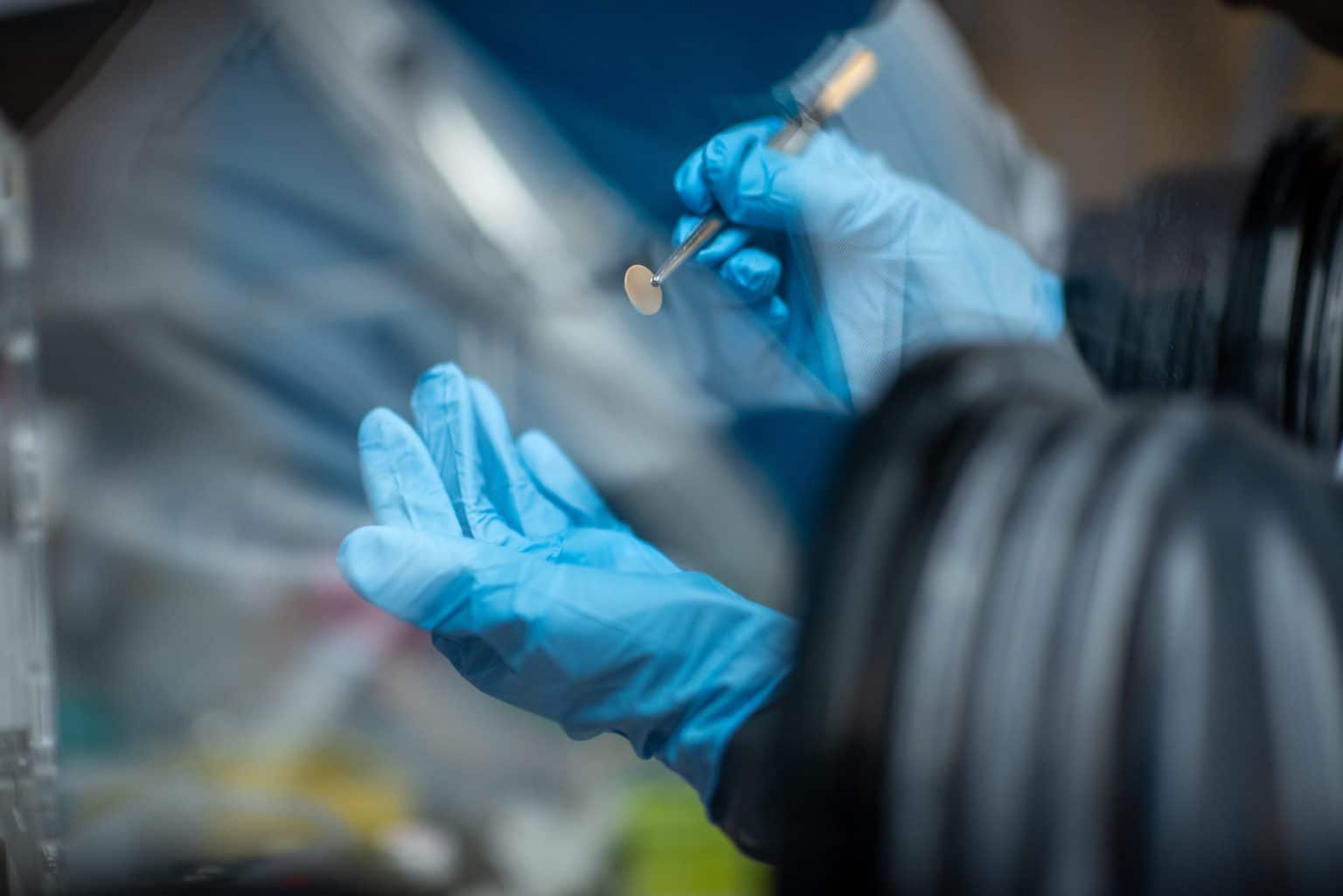

Vulcan Energy has successfully produced its first battery-grade lithium hydroxide monohydrate (LHM) at its Central Lithium Electrolysis Optimization Plant (CLEOP) located in the industrial park of Frankfurt-Höchst. This is the first time that battery-quality LHM has been produced entirely in Europe. The precursor material is sourced from Vulcan’s initial optimization plant, LEOP, using Direct Lithium Extraction through adsorption (A-DLE) from the geothermal brine of the Upper Rhine Graben. It is then processed into LHM at the Frankfurt-Höchst facility. This achievement relies on a highly pure lithium chloride concentrate that the company has been producing since last year at its optimization plant in Landau, Rhineland-Palatinate.

The entire production process is conducted without the use of fossil fuels, resulting in the lowest carbon footprint globally for lithium production. This not only makes Vulcan’s supply chain one of the most sustainable but also one of the most cost-efficient in the world. Establishing a domestic and sustainable lithium supply chain in Europe is a significant step towards strengthening the continent’s raw material independence and advancing the green mobility transition.

The production of the first battery-grade LHM follows just weeks after the operational launch of the optimization plant in November 2024. The lithium product will now be utilized in ongoing qualification processes with Vulcan’s offtake partners in the European automotive and battery industry, including Stellantis, Renault, LG, and Umicore. Simultaneously, the company is progressing with the construction of facilities for the first phase of its project. In this initial phase, dubbed “Lionheart,” Vulcan aims to produce approximately 24,000 tons of LHM annually, sufficient for manufacturing around 500,000 electric vehicles. The planned commercial production plant will also be built in the Höchst industrial park, placing it in close proximity to Vulcan’s customers.

Cris Moreno, Managing Director and CEO of Vulcan Energy, commented: “Congratulations to the entire Vulcan team on the first production of battery-grade LHM in our optimization plant. This is an important milestone for Vulcan and the final step in implementing the first fully domestic and integrated supply chain in Europe that produces battery-grade LHM from local sources. I am very proud of the entire Vulcan operations team, which managed to produce battery-grade LHM within a very short time since the plant started operations in November. This underscores Vulcan’s position as a leading project for lithium and renewable energy in Europe.”

Source: Vulcan Energy Resources