The U.S. Department of Energy’s (DOE) Argonne National Laboratory has unveiled a new design that significantly enhances lithium-ion battery performance while reducing costs. The breakthrough is expected to advance electric vehicle (EV) adoption and support grid energy storage, boosting global decarbonization initiatives. This innovation builds on Argonne’s longstanding expertise in battery research.

In 2012, Argonne researchers advanced the state-of-the-art for lithium-ion batteries with a novel cathode (positive electrode) material that significantly increased energy density and durability. The team fine-tuned the composition of nickel, manganese, and cobalt in cathode particles to optimally harness these metals’ beneficial characteristics.

Khalil Amine, Distinguished Fellow and leader of Argonne’s Advanced Battery Technology team, stated, “This breakthrough material represents an across-the-board improvement for batteries. It features higher storage capacity, robust stability and heat tolerance at high voltages, and longer lifetimes. Its high energy density enables production of smaller, lower-cost batteries, supporting widespread adoption of EVs and grid batteries.”

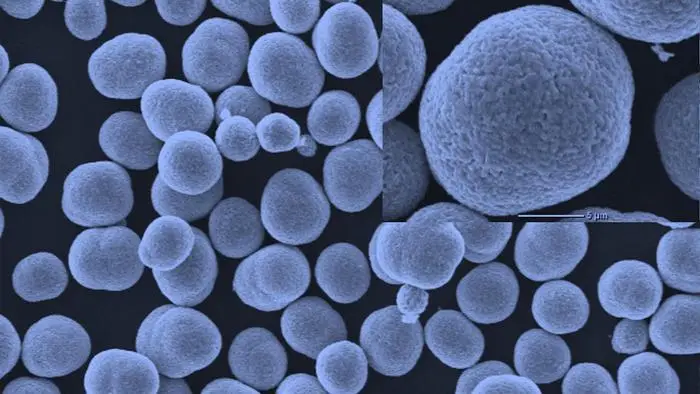

Argonne National Laboratory has introduced a composition gradient design to enhance lithium-ion battery efficiency. By gradually reducing nickel concentration from the core to the particle surface, the design maximizes energy density while minimizing reactivity, producing smaller and more cost-effective batteries. This innovative approach utilizes a layered structure typical of commercial batteries, where ordered metal atom layers facilitate lithium-ion transport between electrodes, essential for the battery’s charge-discharge cycles.

Now licensed to battery and materials manufacturers, this patented design represents a significant technological step forward. Despite the success, Argonne researchers are working on further enhancements to boost battery performance.

“For EVs to replace gasoline-powered vehicles on a global scale, batteries must be able to operate at higher voltages to deliver even more energy and longer driving ranges,” Amine said. “At the same time, they must remain safe and cost less to manufacture.”

High-voltage operations often cause cathode particles with ordered, layered structures to crack and interact with the battery’s electrolyte, which moves lithium ions between electrodes to generate electricity. This process accelerates cathode degradation, diminishing battery capacity and lifetime while raising safety concerns.

To address this, Argonne’s team refined its composition-gradient cathode design by creating particles that transition from disordered material at the surface to an ordered, layered structure at the core. The particles maintain a nickel, manganese, and cobalt gradient, with the surface enriched in cobalt and the interior nearly cobalt-free. This approach combines the stability of a disordered surface—reducing cracking and reactivity—with the optimized ion transport properties of an ordered core, enabling greater capacity and stability for high-voltage applications.

The research team conducted extensive X-ray, electron, and imaging experiments to evaluate the new cathode material at rest and during operation. These tests, performed at the Advanced Photon Source and Center for Nanoscale Materials at Argonne, along with the National Synchrotron Light Source II at DOE’s Brookhaven National Laboratory, aimed to provide detailed insights into the material’s composition, structure, and performance at the cathode, particle, and atomic levels. Results confirmed that the fabrication achieved the intended structure and composition gradients, with the particles demonstrating structural and chemical stability during high-voltage operations.

“We proved that the disordered particle surface is indestructible, with virtually no reactivity or structural strain,” said Tongchao Liu, an Argonne chemist. Liu is the lead author of the Argonne dual-gradient cathode paper, which was recently published in Nature Energy. Collaborating partners include DOE’s Brookhaven and Lawrence Berkeley National Laboratory.

The dual-gradient particles in Argonne’s new design have demonstrated significantly enhanced durability compared to previous models. After 500 charge and discharge cycles, the material retained nearly 98% of its storage capacity, indicating the potential for an extended battery lifespan. The revised design also reduced cobalt content, a critical improvement given cobalt’s scarcity, high cost, and environmental impact during extraction. Analysis showed that cobalt was primarily concentrated on the particle surface, with interior levels reduced to under 2%, a significant decrease from the 10-20% found in the original design.

“We plan to reduce the cobalt level down to 1%,” said Amine. “This helps us make batteries much more sustainable.”

The team further reported that the new design improved the cathode’s heat tolerance—a key factor for safe, high-voltage operations.

This study represents the first successful integration of composition and structure gradients within a single cathode particle. The innovation is anticipated to pave the way for further research into cathodes that combine varied structures and compositions, advancing overall battery performance.

“This breakthrough material represents an across-the-board improvement for batteries,” said Amine. “It features higher storage capacity, robust stability and heat tolerance at high voltages, and longer lifetimes. Its high energy density enables production of smaller, lower-cost batteries, supporting widespread adoption of EVs and grid batteries. Our patented design and fabrication process is ready to be licensed by industry.”

Publications: Ultrastable cathodes enabled by compositional and structural dual-gradient design. Nature Energy, 9, 1252-1263. https://doi.org/10.1038/s41560-024-01605-8

Source: Argonne