CSEM has unveiled Switzerland’s first dry room, a state-of-the-art facility designed to enhance the development and prototyping of next-generation batteries. This new facility, part of CSEM’s Battery Innovation Hub (BIH), is set to become operational in September 2025 and is the first of its kind among Swiss research institutions and universities. The dry room features an ultra-low dew point of −50°C, creating an optimal environment for handling moisture-sensitive materials such as lithium metal, which is essential for high-energy-density batteries.

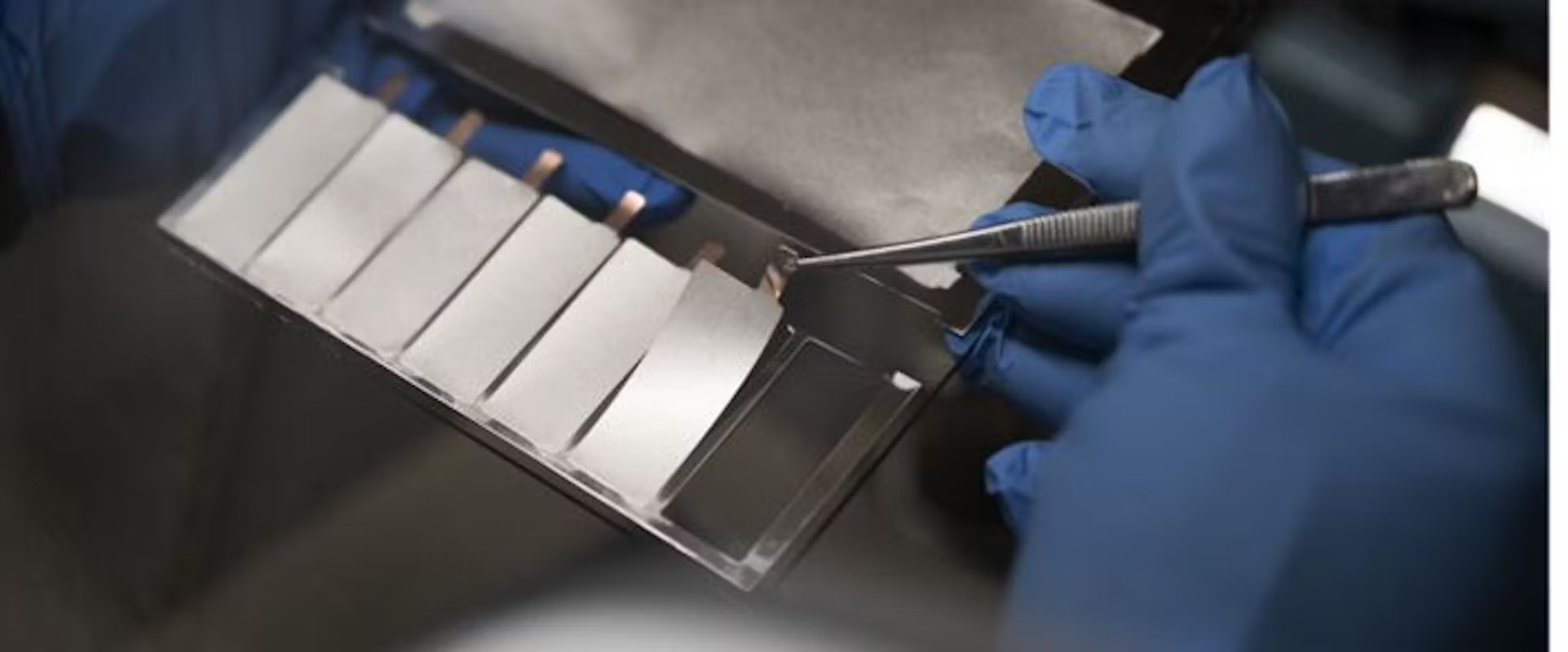

The facility includes a pilot production line for assembling pouch cells, commonly used in smartphones and electric vehicles, bridging the gap between prototypes and industrial-scale production. Additionally, a 10-square-meter section is allocated for start-ups and small- and medium-sized enterprises (SMEs), offering these smaller companies access to high-tech infrastructure. This allocation aims to reduce the risks and costs associated with innovation, providing strategic opportunities for emerging businesses to advance their battery technologies.

Andrea Ingenito, co-director of the Battery Innovation Hub, highlighted the significance of the dry room, stating, “CSEM’s dry room isn’t just a technical upgrade—it’s a key enabler for proving the industrial viability of the technologies developed within our Battery Innovation Hub.” The controlled environment allows researchers and engineers to rapidly test and iterate new technologies, particularly benefiting materials like lithium metal. This capability is expected to accelerate the refinement of breakthrough technologies, ensuring they meet industry standards and facilitating their transition to large-scale production and adoption.

Spanning 37 square meters, the dry room also includes a pilot line capable of assembling pouch cells with a capacity of up to 5 ampere-hours (5Ah). This capacity is sufficient to power a 1-ampere device for five hours or a 5-ampere device for one hour, demonstrating the facility’s potential for developing practical battery applications. By providing access to advanced equipment and CSEM’s expertise in battery technology, the dry room supports start-ups and SMEs in advancing their innovations to higher technology readiness levels (TRL) and moving towards industrialization.

CSEM’s initiative is part of a broader effort to showcase Swiss technological excellence and strengthen the country’s industrial competitiveness. The new dry room is expected to play a pivotal role in overcoming manufacturing challenges associated with solid-state lithium-metal batteries, which promise higher energy density, lower costs, faster charging times, and improved safety for the electric vehicle market. “New materials and manufacturing techniques present a unique opportunity to rebuild Europe’s battery industry,” Ingenito added, emphasizing the strategic importance of Switzerland’s advancements in this field.

Source: CSEM