Farasis Energy, a Chinese manufacturer of power batteries, has announced significant progress in the development of its all-solid-state battery technology. The company revealed that its all-solid-state battery, boasting an energy density exceeding 400 Wh/kg, has entered the testing phase with stable cell cycling performance.

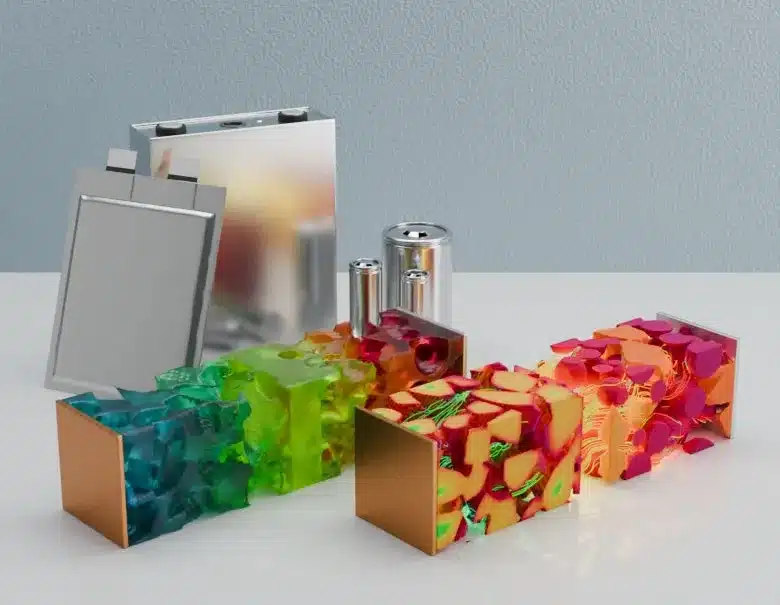

The new battery utilizes a sulfide-based electrolyte system, combining a high-nickel ternary cathode with a high-silicon anode. This configuration enhances the battery’s energy density and overall performance. Farasis Energy emphasized the improved safety features of the cells, which have successfully passed rigorous tests including pinprick, shear, and hot box assessments. Additionally, the cells exhibit thermal runaway self-shutdown capabilities at the cell level, further enhancing safety.

In the field of solid-state batteries, three primary technological routes are being explored: oxide, polymer, and sulfide. Farasis Energy is actively developing batteries across all three routes. Notably, the company has developed a prototype solid-state battery using a lithium metal anode and a high-nickel cathode, achieving an impressive energy density of up to 500 Wh/kg. The development of composite electrolyte materials compatible with lithium metal anodes and high-nickel cathodes marks a critical advancement in their research.

Farasis Energy currently adopts a production process that includes high-nickel ternary materials, soft pack packaging, and laminated cell construction. This process aligns with the main technological route for solid-state battery production. The company stated that as solid-state battery systems mature and industrialization progresses, their existing equipment and processes can seamlessly integrate the new solid-state battery technologies.

Prior to this latest development, Farasis Energy had introduced three generations of semi-solid-state batteries. The first generation, with energy densities between 280-300 Wh/kg, entered mass production in 2022. These batteries have been adopted by customers such as Dongfeng Motor, GAC Group, Geely, and several international clients. The second-generation semi-solid-state battery offers an energy density of 330 Wh/kg, supports fast-charging capabilities exceeding 3C rates, and boasts a cycle life of over 4,000 cycles. This generation has undergone Design Verification and Production Validation testing and is preparing for small-scale mass production, having gained recognition from key customers in the high-end passenger vehicle and low-altitude economy sectors.

The third-generation semi-solid-state battery developed by Farasis Energy achieves an energy density of up to 400 Wh/kg. It is currently undergoing automotive-grade certification and further development, signaling the company’s ongoing commitment to advancing battery technology for future applications.

Source: CnEVPost