Hyundai Motor and Kia are increasing their electric vehicle (EV) production in the United States, leveraging their dedicated facility, Metaplant America (HMGMA), which is set to begin full-scale mass production of the Ioniq 5 next month. This expansion is a key component of the automakers’ strategy to strengthen their foothold in the competitive U.S. EV market.

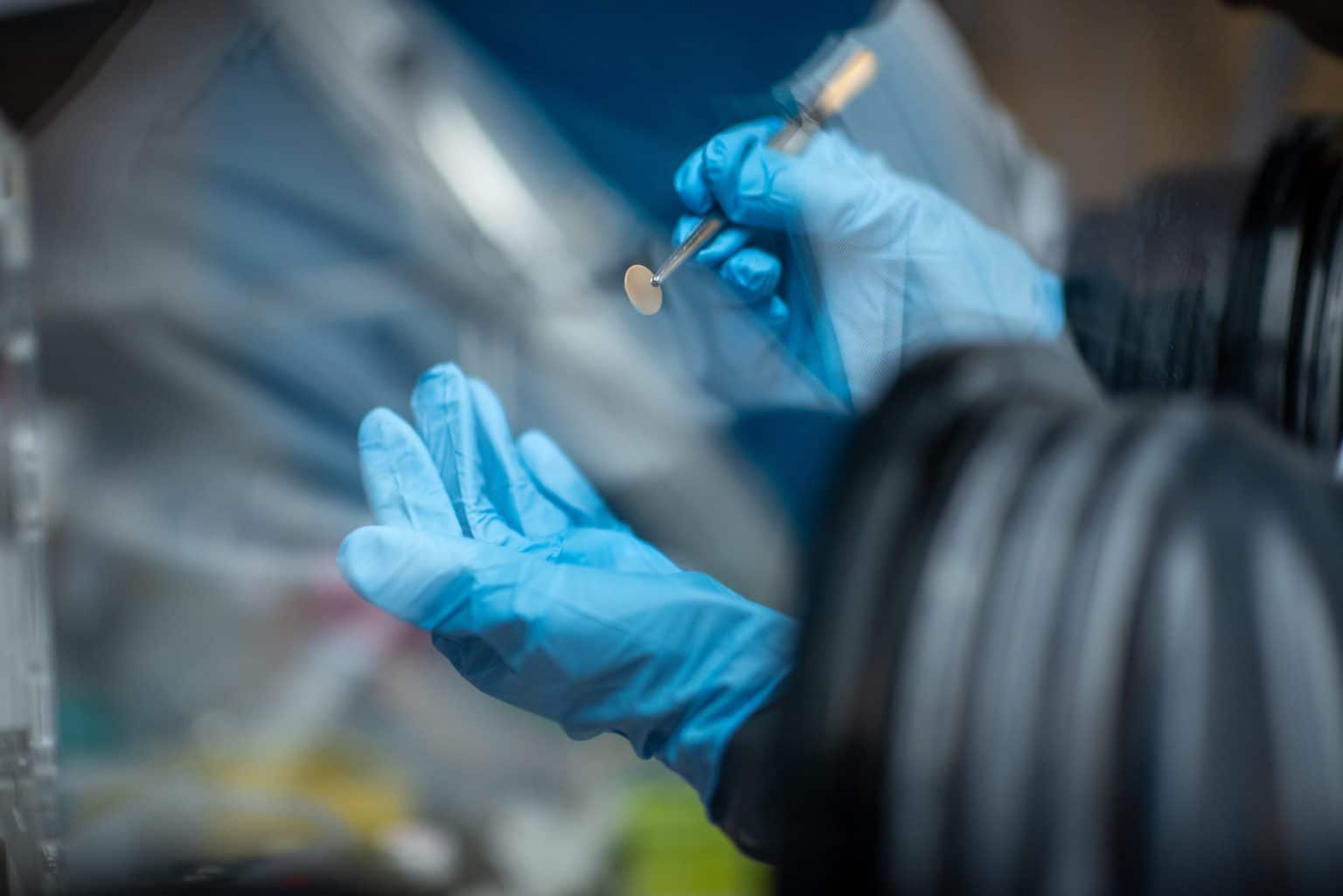

Supporting this growth, SK On, a subsidiary of SK Innovation, is significantly enhancing its battery manufacturing capabilities in the U.S. SK On’s U.S. branch, SK Battery America (SKBA), will start producing batteries for Hyundai and Kia EVs on nine out of its twelve production lines at the Georgia Plant 1 and 2 as early as next month. This shift will result in 75% of SK On’s local production lines being dedicated to supplying batteries for these automakers.

The Georgia plant’s strategic location enables efficient logistics, with batteries being transported to HMGMA within four hours by land. This proximity reduces both transportation time and logistics costs compared to importing batteries from South Korea and Europe. The plant has an annual production capacity of approximately 16.5 GWh, which is sufficient to support around 200,000 electric vehicles.

An industry insider mentioned, “Hyundai and Kia, SK On’s largest customers, are gaining popularity in the market, setting new records in U.S. electric vehicle sales despite the global EV demand slowdown.” The increased battery demand is anticipated to enhance SK On’s plant operation rate, which was at 46.2% in the third quarter of the previous year.

Additionally, the expansion is expected to benefit from the production tax credit (AMPC) under the U.S. Inflation Reduction Act (IRA). Last year, SK On received approximately 292.4 billion won from AMPC. Electric vehicles equipped with locally produced batteries from SK On’s Georgia plant are eligible for purchase subsidies up to $7,500, aligning with the IRA’s requirements for maximum subsidies.

However, potential political changes, such as a second term for Donald Trump, present challenges. President Trump has expressed opposition to tax credits and incentives for EVs and batteries. Despite this, there is speculation that his proposed tariffs on imported cars could advantage local EV and battery manufacturers. Jeon Hyun-wook, head of SK On’s Financial Support Office, stated, “Considering various factors such as local employment, we believe it will not be easy to eliminate AMPC,” and added, “The U.S. government’s policy changes present opportunities not only in subsidy reduction but also in tariffs and other complex perspectives related to China policy.”

Source: Business Korea