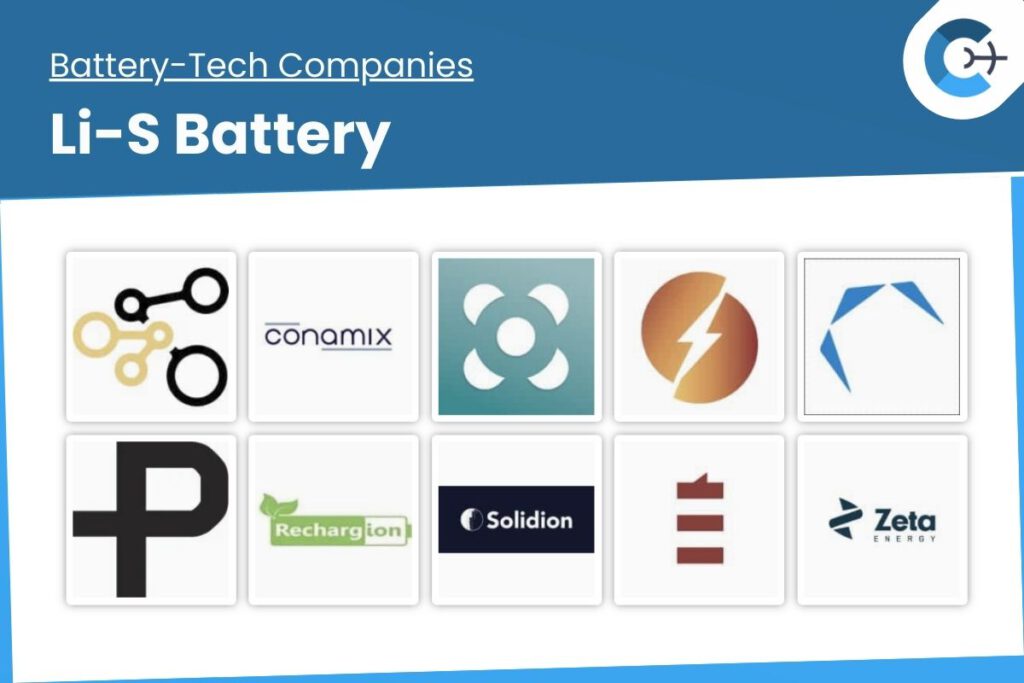

Key Players in Lithium-Sulfur Battery Technology and Production

Alteva Technologies

Alteva Technologies GmbH, based in Cologne, develops ultra-lightweight lithium-sulfur batteries derived from DLR research. Their batteries are three times lighter than traditional lithium-ion, advancing electrification in aviation, long-haul trucking, and heavy machinery with high performance and sustainable design.

Conamix

Conamix, founded in 2014 in Ithaca, NY, develops innovative lithium-sulfur batteries for electric vehicles. Their cost-effective, high-density technology uses abundant sulfur, enhancing EV range and sustainability while eliminating costly materials like cobalt and nickel.

Gelion

Gelion plc, headquartered in London and listed on AIM, pioneers lithium-sulfur and zinc-bromide energy storage solutions. Originating from the University of Sydney, the company delivers sustainable technologies for renewable energy, aerospace, and automotive applications, supported by strategic partnerships and robust investments.

Li-S Energy

Li-S Energy Limited, based in Brisbane, Australia, leads in developing advanced lithium-sulfur and lithium metal battery technologies. Their innovative Li-nanomesh™ and BNNT solutions enable lighter, safer, and higher-energy storage for diverse applications.

Lyten

Lyten, based in San Jose, specializes in lithium-sulfur batteries using proprietary 3D Graphene technology. Offering double the energy density of lithium-ion and reduced environmental impact, their sustainable solutions serve automotive, aerospace, and energy sectors. Lyten is expanding production with a Nevada gigafactory and has strong investor backing.

PolyPlus Battery Company

PolyPlus Battery Company, based in Berkeley since 1991, specializes in high-energy-density lithium-based batteries. Utilizing proprietary technologies like Glass Protected Li Metal Batteries and PLE™, they provide efficient solutions for automotive, medical, drones, and underwater applications. Backed by significant investments, PolyPlus drives next-generation energy storage.

Rechargion Energy

Rechargion Energy Pvt Ltd, founded in 2021 in Pune, develops sustainable energy storage solutions using advanced Sodium-ion and Lithium-Sulfur batteries. Focusing on mobility and stationary applications, their innovative technologies offer cost-effective, environmentally responsible options, highlighted by drone projects and strategic partnerships.

Solidion Technology Inc.

Solidion Technology Inc., based in Dallas, specializes in advanced battery technologies for electric vehicles and renewable energy. Holding over 500 patents, the company leads in silicon anodes, nanostructured graphene-sulfur cathode, sustainable graphite production, and graphene-enhanced fast-charging solutions.

theion

Founded in 2020 in Berlin, Theion GmbH develops lithium-sulfur batteries with sulfur crystal technology. Their batteries offer triple the energy density of lithium-ion alternatives at lower costs, supporting electric mobility, aviation, and renewable energy storage with improved performance and sustainability.

Xponential Battery Materials

Xponential Battery Materials (XBM), established in 2020 in Los Angeles, develops sustainable cathode materials using industrial byproducts. Their innovative approach supports next-generation Li-S and solid-state batteries for domestic applications.

Zeta Energy Corp.

Zeta Energy Corp., headquartered in Houston since 2014, develops advanced lithium-sulfur batteries that offer triple the energy density of lithium-ion at half the cost. By eliminating critical materials, Zeta provides sustainable energy storage solutions for electric vehicles and renewable systems. Partnered with Stellantis and backed by over $27 M in funding, the company leads in innovative, eco-friendly battery technology.

Lithium-Sulfur Battery Technology Overview

Lithium–Sulfur batteries are gaining attention as a future storage solution that can significantly increase energy density while lowering production expenses. This battery type uses lithium metal as the anode and sulfur as the cathode, taking advantage of sulfur’s availability and cost benefits. Applications in electric vehicles, grid storage, and portable electronics are driving research that may result in new power sources with higher energy outputs and reduced environmental impact.

Key characteristics of the technology

- High Energy Density: Lithium–Sulfur batteries have the potential to store multiple times the energy of conventional lithium-ion cells. This makes them especially attractive for applications where weight and space are critical considerations.

- Material Efficiency: With sulfur serving as the cathode active material, the technology benefits from lower material costs compared to batteries that use metals such as cobalt or nickel.

- Lightweight Construction: The combination of lithium metal anodes and sulfur cathodes results in cells that are significantly lighter than traditional battery designs. This aspect is beneficial for vehicles and aerospace platforms where weight reduction can improve performance.

- Chemical Process: The working mechanism involves a sequence where sulfur is reduced to form lithium polysulfides before eventually converting into lithium sulfide during discharge. Controlling these chemical transitions is essential to maintain performance and longevity.

Technology classifications / types

Lithium–Sulfur systems can be grouped based on material design and cell configuration:

Conventional Li–S Cells:

These cells use established electrode structures and liquid electrolytes. Researchers continue to adjust electrolyte formulations to better manage intermediate compounds during discharge.

Hybrid Electrolyte Systems:

Variants that employ solid or quasi-solid electrolytes show promise in reducing unwanted side reactions. The design aims to improve the movement of ions while limiting the effects caused by soluble by-products.

Nanostructured and Carbon Framework Designs:

Many recent developments focus on integrating nanomaterials into the cathode to trap soluble polysulfides and prevent active material loss over repeated cycles.

Development and commercialization challenges

- Cycle Life and Stability: A primary issue remains the gradual loss of capacity as discharge cycles progress. The polysulfide shuttle, wherein by-products travel between electrodes, can lead to a reduction of active material and overall performance degradation.

- Optimizing Electrolytes: Finding formulations that promote efficient ion transfer while fending off side reactions is an ongoing design challenge. Research is exploring both polymer-based and ionic liquid additives to improve stability.

- Mechanical and Chemical Durability: Repeated cycling induces stress on electrode interfaces. New strategies in material design and electrode architecture are being tested to reduce damage during charge–discharge operations.

Recent developments and examples

- PolyPlus Battery Company: Has introduced a protected lithium electrode (PLE) system. This approach facilitates the use of lightweight lithium metal anodes and is part of ongoing efforts to refine solid electrolyte concepts for both Li–S and lithium–air battery formats.

- Li–S Energy Limited: Is developing battery designs that incorporate boron nitride nanotubes to improve energy density and extend the number of viable charge cycles. Their partnerships with academic institutions are providing fresh insights for potential applications in electric vehicles and aerospace.

- Lyten, Inc.: Is experimenting with three-dimensional graphene that nearly doubles energy storage compared to conventional cells. The company is preparing for pilot production in association with several automotive and defense organizations.

- theion GmbH: The German battery startup Theion has secured €15 million ($16.4 million) in a Series A funding round to advance its sulfur battery technology.