A research team led by Hailong Chen at the Georgia Institute of Technology has developed a low-cost iron chloride cathode (FeCl₃) for lithium-ion batteries (LIBs). This innovation could significantly reduce costs and enhance performance for electric vehicles (EVs) and large-scale energy storage systems.

“For a long time, people have been searching for a more affordable and sustainable alternative to existing cathode materials. I believe we’ve found one,” said Chen, an associate professor in the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering.

The new cathode material costs only 1–2% of traditional cathode materials yet can store the same amount of electricity. Cathode materials are crucial for determining a battery’s capacity, energy, and efficiency, directly impacting its performance, lifespan, and affordability.

“Our cathode can be a game-changer,” Chen stated. “It could greatly improve the EV market and the entire lithium-ion battery industry.” The team’s work is detailed in the journal Nature Sustainability.

Advancing Lithium-Ion Battery Technology

First commercialized in the early 1990s, LIBs revolutionized personal electronics and later became essential for powering electric vehicles. However, the high cost of LIBs, largely due to expensive metals like cobalt and nickel used in cathodes, has been a barrier to wider adoption of EVs.

Currently, batteries account for about 50% of an EV’s total cost, making them more expensive than traditional internal combustion vehicles. The new FeCl₃ cathode could significantly reduce this cost.

Compared to conventional alkaline and lead-acid batteries, LIBs offer higher energy storage in a smaller package. However, their reliance on costly and environmentally challenging metals has limited their affordability and sustainability.

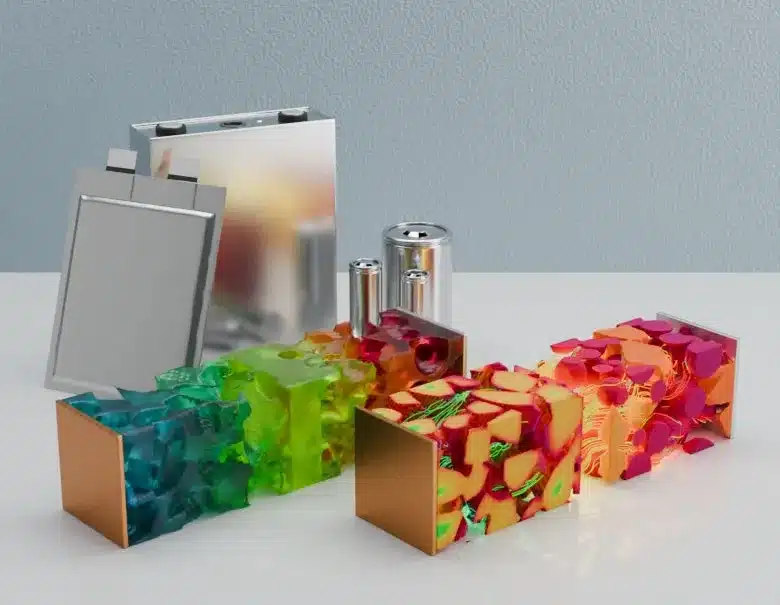

Chen’s cathode would represent the fifth type of cathode to be successfully commercialized for LIBs and marks a significant step toward developing all-solid-state lithium-ion batteries.

All-solid-state LIBs use solid electrolytes instead of liquid ones, enhancing efficiency, safety, and energy storage capacity. While this technology is still under development, Chen’s team has made strides by pairing the FeCl₃ cathode with a solid electrolyte and a lithium metal anode, resulting in a battery system that costs 30–40% less than current LIBs.

“This could not only make EVs much cheaper than internal combustion cars but also provide a promising solution for large-scale energy storage, enhancing the resilience of the electrical grid,” Chen said. “Additionally, our cathode would greatly improve the sustainability and supply chain stability of the EV market.”

Iron Chloride Cathode – From Concept to Reality

Chen’s interest in FeCl₃ as a cathode material began with research into solid electrolyte materials. Initially, his team faced compatibility issues when combining chloride-based solid electrolytes with traditional oxide-based cathodes. This led them to explore chloride-based cathodes, resulting in the successful implementation of FeCl₃.

Unlike commonly used cathodes that require large amounts of costly and potentially toxic metals like nickel and cobalt, the FeCl₃ cathode is composed of abundant and affordable elements—iron and chlorine.

Initial tests have shown that FeCl₃ performs as well as or better than more expensive cathodes, offering a higher operational voltage compared to lithium iron phosphate (LFP), a commonly used cathode material.

The technology could be commercially viable for EVs within five years. The research team plans to continue investigating FeCl₃ and related materials to optimize performance and understand underlying mechanisms.

Collaborators on the project include researchers from Georgia Tech’s Woodruff School of Mechanical Engineering (Ting Zhu), the School of Earth and Atmospheric Sciences (Yuanzhi Tang), Oak Ridge National Laboratory (Jue Liu), and the University of Houston (Shuo Chen). The study was led by Chen and postdoctoral researcher Zhantao Liu, the lead author.

“We aim to perfect the materials in the lab and deepen our understanding of how they function,” Chen said. “We are also open to opportunities to scale up the technology for commercial applications.”

Reference: Liu, Z., Liu, J., Zhao, S., Xun, S., Byaruhanga, P., Chen, S., Tang, Y., Zhu, T., & Chen, H. (2024). Low-cost iron trichloride cathode for all-solid-state lithium-ion batteries. Nature Sustainability.

Source: Georgia Tech – News Center