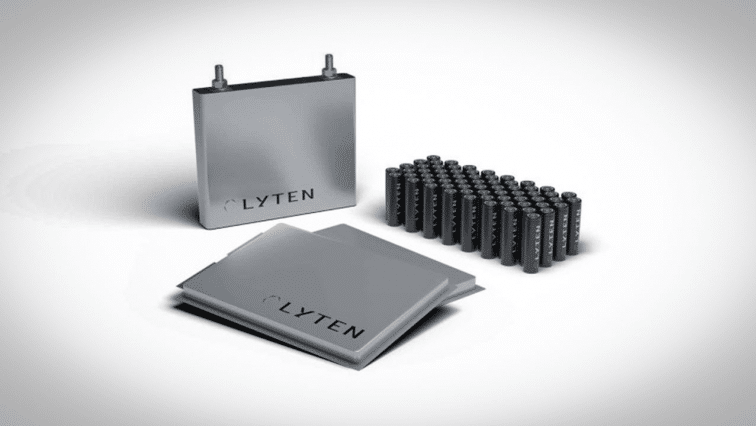

Lyten, a leader in supermaterial applications and lithium-sulfur battery technology, has announced a new initiative aimed at enhancing the performance of U.S. defense drones. This program focuses on developing next-generation drone propulsion systems powered by Lyten’s ultra-lightweight lithium-sulfur (Li-S) batteries. To support this effort, Lyten is allocating significant production capacity at its California manufacturing facilities to address the specific requirements of the U.S. defense, unmanned aerial vehicle (UAV), and satellite sectors.

The company’s domestically sourced and manufactured Li-S batteries are designed to assist the Department of Defense in achieving two key modernization goals: minimizing reliance on foreign and adversarial supply chains for critical minerals and components, and facilitating the deployment of UAVs that are lighter, have longer ranges, and greater operational capabilities. Lyten Co-Founder and CEO Dan Cook emphasized the importance of reducing dependence on geopolitical rivals by providing locally produced high-performance battery solutions.

In a recent demonstration, Lyten showcased its Li-S battery technology powering a 3D-printed UAV developed by Titan Dynamics, with a battery pack designed by Upgrade Energy. The successful flight of the drone, featuring an 8.5-foot wingspan, lasted over three hours and reached speeds of up to 86 mph during maneuvers in Palos Verdes, California. Lyten is planning to release an improved battery variant that aims to extend flight times to up to eight hours for the Titan Dynamics platform.

Lyten’s lithium-sulfur batteries are notable for being free from nickel, manganese, cobalt, and graphite—materials typically controlled by Chinese supply chains. This composition ensures compliance with the National Defense Appropriations Act (NDAA) and provides a secure energy solution for defense applications. The higher energy density of Li-S batteries supports longer flight durations, heavier payloads, and extended operational ranges for UAVs.

Celina Mikolajczak, Lyten’s Chief Battery Technology Officer, highlighted the critical role of lightweight propulsion in various industries, including satellites, electric vehicles, and micromobility. She noted that Lyten’s Li-S battery platform not only offers lightweight performance but also avoids materials that are subject to supply chain constraints.

Additionally, Lyten is currently accepting orders for its latest Li-S batteries designed for drones and has secured a contract with the Defense Innovation Unit to demonstrate its technology on the International Space Station, scheduled for launch later this year. The company’s batteries are achieving over 3,000 cycles for satellite applications, underscoring their durability and reliability.

Source: Business Wire