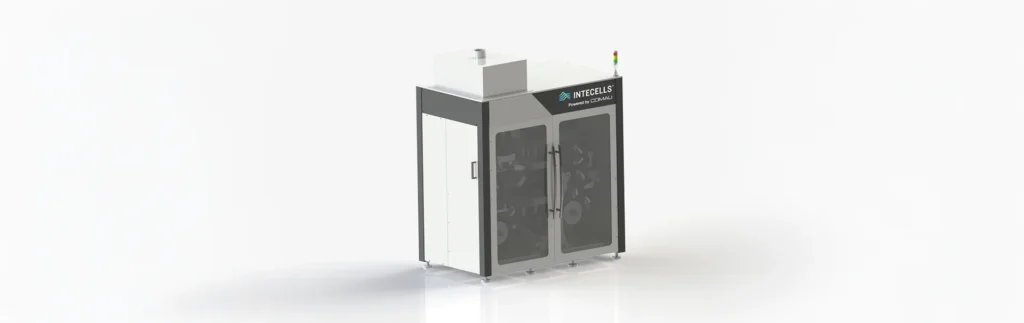

Comau has entered into a strategic collaboration with Michigan-based Intecells to advance battery electrode manufacturing through the application of cold plasma technology. Under the partnership, Comau will leverage Intecells’ patented cold plasma processes to create a cost-effective integration path for existing cell production lines.

The initial plasma-based solution can be added to standard slurry-coating systems to reduce soaking and drying cycle times and lower energy consumption. Early trials have demonstrated improvements in cell capacity, cyclability, and overall production quality across various battery chemistries and form factors. By removing the need for solvents and binders, the approach also addresses environmental and safety considerations in electrode fabrication.

A next-generation plasma platform is currently under development, which aims to significantly streamline the manufacturing workflow. The joint teams are targeting a 50 percent reduction in capital expenditures, along with halved energy requirements and carbon emissions throughout the electrode production process.

Comau, a global provider of advanced automation solutions, offers technologies that span the full battery lifecycle—from cell formation to module and pack assembly, testing, and end-of-life recycling. In partnering with Intecells, the company seeks to validate and scale disruptive plasma treatments within high-volume manufacturing environments.

“Combining Intecells’ disruptive cold plasma technology with Comau’s expertise in electrification automation enables a practical integration route for next-generation electrode processes,” said Gian Carlo Tronzano, Head of Comau’s Battery Cell Global Competence Center and P&E e-Mobility division.

Our collaboration with Intecells marks a pivotal step in redefining how battery cells are manufactured. By combining Intecells’ disruptive technology with Comau’s electrification technology and expertise, we are working to deliver a practical path for integrating next-generation plasma processes into existing production lines, starting with the validation of cold plasma technology within scalable manufacturing operations,” said Gian Carlo Tronzano, Head of Battery Cell Global Competence Center and of P&E e-Mobility

“Our partnership with Comau gives Intecells the means needed to accelerate development, will revolutionize the way battery cells are manufactured and will support our customers globally,” added Xiaohong Gayden, founder and CEO of Intecells.

Intecells’ platform is already compatible with current slurry-based lines and is slated to support upcoming dry-coating processes for solid-state and advanced cells. The partnership aligns with industry efforts to reduce manufacturing costs, energy use, and CO₂ emissions while enhancing cell performance and safety.

Source: Comau