Pure Lithium, a vertically integrated lithium metal battery technology company, has selected Voltaiq’s Enterprise Battery Intelligence platform to support its transition from research and development to commercialization. The partnership will enable advanced battery analytics and quality control for Pure Lithium’s next-generation metal battery cells.

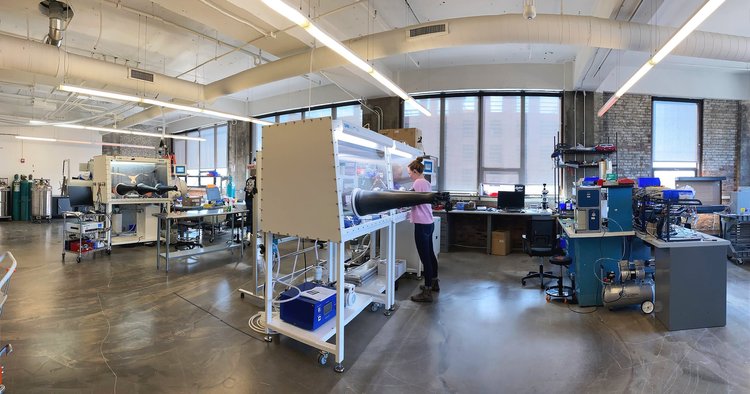

Relocating operations to Chicago, Pure Lithium is building its first pilot production line and preparing to ship sample cells to customers. Previously relying on an in-house analytics system, the company sought a scalable solution with deep battery and software expertise. Voltaiq’s platform offers real-time monitoring and advanced analytics that can detect manufacturing defects up to several weeks earlier than traditional quality control methods, potentially reducing factory ramp-up time by more than 50 percent.

Under the multi-year agreement, Voltaiq will provide a secure, cloud-hosted system of record for current and historical battery data, ensuring uninterrupted operations during Pure Lithium’s cross-country move. The platform will also help optimize production processes, accelerate customer deliveries, and deliver cost savings compared to developing internal software tools.

“As we bring a new anode production method online – something nobody has ever done before – we need a battery analytics platform that is robust and commercially focused,” said Pure Lithium Founder and Chief Executive Officer Emilie Bodoin. “Just because you can build it, doesn’t mean you should. In today’s competitive environment, there is no dollar amount you can put on speed to market. We found the right software partner in Voltaiq and are accelerating our commercialization progress while freeing our team to focus on what they do best.”

“The Voltaiq team is proud to support Emilie and her team at Pure Lithium as they bring this much needed technology to market,” said Tal Sholklapper, Co-Founder and Chief Executive Officer of Voltaiq. “Lithium metal batteries, made from lithium that can be refined domestically, have transformational potential for the entire battery industry.”

Pure Lithium’s Brine to Battery™ process combines metal extraction and anode production to yield a pure lithium metal anode, offering improvements in cell performance, cost, and safety without graphite, cobalt, nickel, or manganese. Voltaiq’s analytics platform is already used across battery manufacturing and validation labs by leading companies.

Source: Business Wire