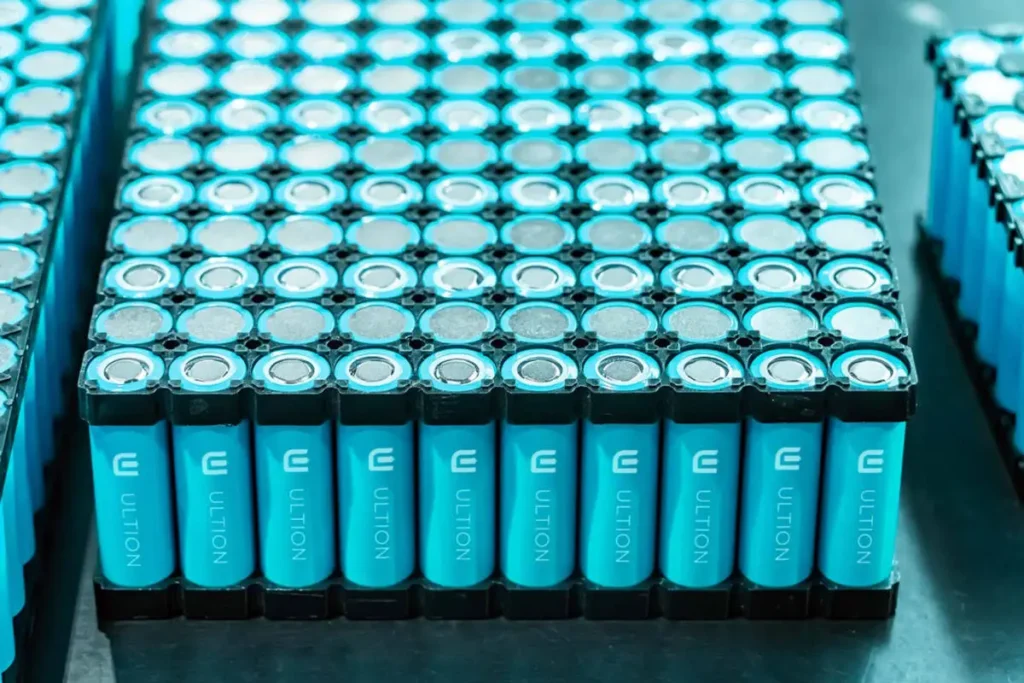

Ultion Technologies has achieved a milestone in North American energy storage by producing and validating lithium iron phosphate (LFP) battery cells made exclusively from regional materials. Tested at commercial scale, these cells deliver performance on par with—and in some cases exceeding—imported alternatives, particularly at high discharge rates.

This development addresses growing concerns over reliance on foreign battery imports and aligns with U.S. policy efforts to establish a domestic supply chain. The project is the result of a collaboration between Ultion, a Nevada-based battery design and assembly firm, and First Phosphate, a Canadian mineral developer that provided high-purity phosphate and iron for the cathode. The partners signed a memorandum of understanding in 2023 to advance a fully North American LFP value chain from raw materials to finished cells.

“We can now point to a working battery cell and say every critical material came from North America,” said Johnnie Stoker, CEO of Ultion Technologies. “From mine to finished cell, the supply chain is real, and the performance matches or surpasses what global leaders are putting on the market.”

According to Ultion’s tests, the cells were manufactured in a standard 18650 cylindrical format and independently validated to offer a stable capacity of 1.6 amp-hours (Ah). Projections indicate at least 2,000 charge-discharge cycles with retention of 80 percent capacity. Performance consistency was confirmed by minimal cell-to-cell variation, and cells maintained strong stability at a 5C discharge rate—ten times faster than typical commercial LFP products. Such high-rate capability is especially relevant for grid storage, data centers, and defense applications that require rapid power delivery.

China currently accounts for more than 90 percent of global LFP cell production, and recent supply chain disruptions have underscored the risks of that concentration. Ultion’s achievement demonstrates that North America can build competitive manufacturing capacity using locally sourced inputs. Torus, a Utah-based provider of hybrid flywheel and battery storage systems, has invested in Ultion and committed to procuring these North American cells for its utility, data center, and commercial projects.

“We can now point to a working battery cell and say every critical material came from North America,” said Johnnie Stoker, CEO of Ultion Technologies. “From mine to finished cell, the supply chain is real, and the performance matches or surpasses what global leaders are putting on the market.”

“American innovation and manufacturing can compete head-to-head with any battery technology in the world,” Stoker said. “We are demonstrating performance that surpasses imports, while creating jobs and strengthening energy security.”

“Ultion’s progress gives us reliable supply, strong performance, and a clear competitive edge,” said Nate Walkingshaw, CEO of Torus. “What excites us most is the combination of performance and strategic value. We can now offer our utility and data center customers storage systems that are built in America and exceed the capabilities of imported alternatives.”

Ultion Technologies, headquartered in Las Vegas, focuses on LFP materials, cell design, and pack assembly to support grid resilience and energy independence in North America.

Source: Business Wire