SK On, a global battery and trading company, has announced significant advancements in the research and development of all-solid-state batteries (ASSBs). Collaborating with renowned Korean universities and institutions, the company’s latest research findings have been featured in prestigious international academic journals. The South Korean battery giant also filed patent applications for several of its research findings, both domestically and internationally.

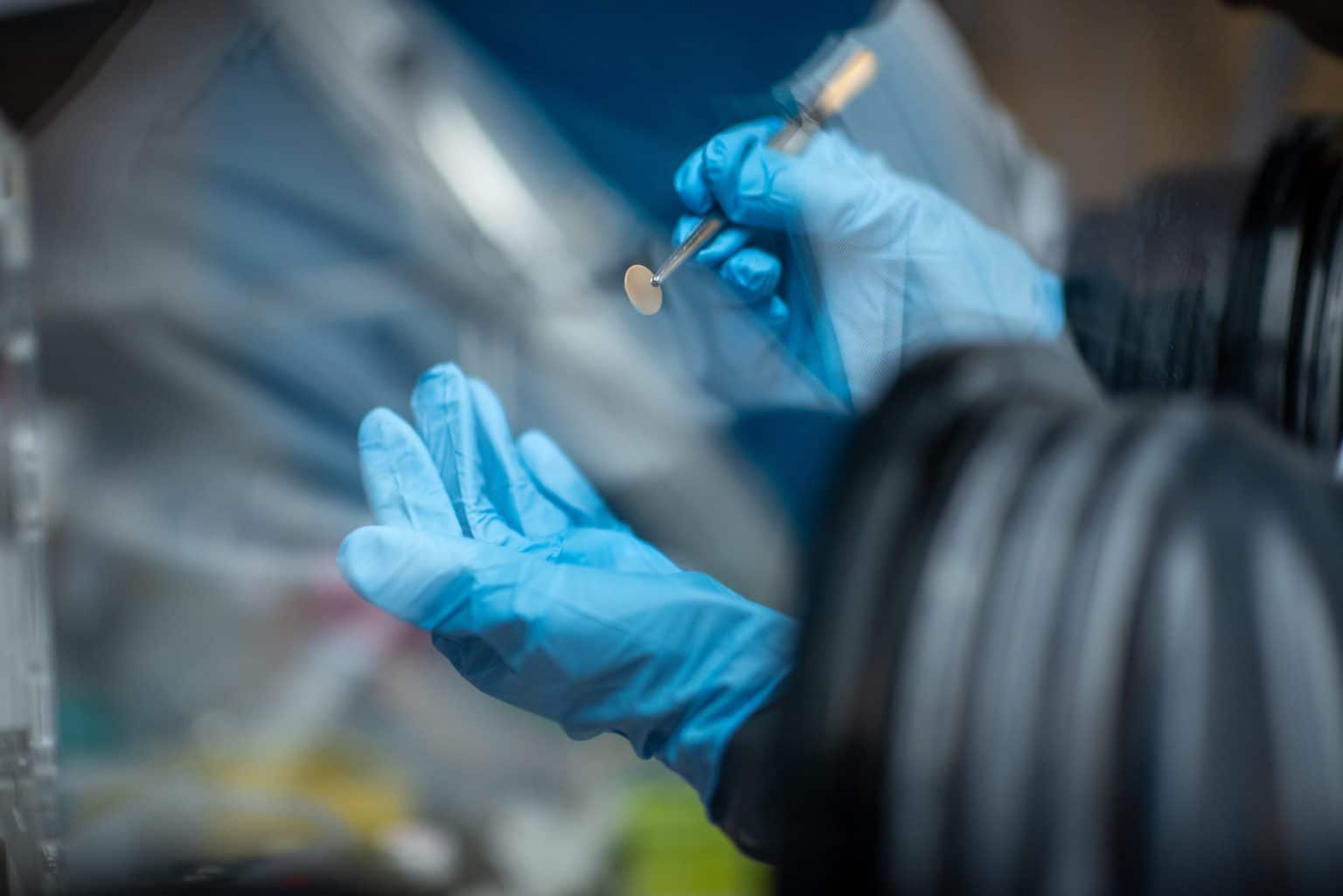

One notable study conducted with Dr. Jin Ho Kim’s team at the Korea Institute of Ceramic Engineering and Technology focuses on using ultrafast photonic sintering technology to manufacture oxide-rich inorganic-organic composite hybrid solid electrolytes. This approach is groundbreaking because it applies photonic sintering—traditionally used in printed circuit board manufacturing—to the development of ASSBs. The research was published as a cover article in ACS Energy Letters, a leading journal in energy and chemistry, with six of the nine authors hailing from SK On.

ASSBs are batteries that utilize solid electrolytes instead of the liquid electrolytes found in conventional lithium-ion batteries. These solid electrolytes are categorized into sulfide-based, oxide-based, and polymer-based types. Oxide-based electrolyte materials generally require high-temperature heat treatment at over 1,000 degrees Celsius for more than 10 hours to enhance lithium-ion transport pathways and mechanical strength. This process is costly and poses challenges like brittle fractures, which hinder scalability.

To overcome these obstacles, SK On explored photonic sintering due to its speed and lower temperature requirements. The research team identified inorganic colorants that minimize energy loss during light exposure and applied them to oxide electrolyte materials. By employing ultrafast photonic sintering technology, they produced a porous microstructure with optimal uniformity. They then created a hybrid solid electrolyte by combining the photonic sintering-processed oxide-based materials with a gel polymer electrolyte, resulting in batteries that demonstrated excellent cycle life.

In another study, SK On investigated lithium- and manganese-rich layered oxide (LMRO) cathodes for sulfide-based ASSBs in collaboration with Professor Kyu Tae Lee’s team at Seoul National University. This research was featured as a cover article in Advanced Energy Materials, a prominent journal in energy materials, and was recognized for its comprehensive analysis of the degradation mechanisms of LMRO cathodes.

LMRO cathode materials are cost-effective due to their manganese base, which is less expensive than nickel and cobalt. However, when used with liquid electrolytes in traditional lithium-ion batteries, LMROs face issues like gas generation, voltage decay, and capacity loss. The research team discovered that oxygen released during charging and discharging oxidizes the sulfide solid electrolyte, leading to degradation. By applying a special coating material to suppress oxygen release, they successfully enhanced the batteries’ cycle life.

“These achievements are the result of SK On’s proactive R&D efforts and exceptional technical capabilities, creating synergy with experts from academia and institutions,” said Kisoo Park, Head of SK On’s R&D Division. “We will remain committed to advancing R&D to drive leadership in the next-generation battery sector.”

SK On is developing two types of ASSBs: polymer-oxide composite and sulfide-based, with commercial prototypes expected by 2027 and 2029, respectively. The company’s solid-state battery pilot facility, currently under construction at its research center in Daejeon, South Korea, is slated for completion in the second half of 2025.

Source: SKinno News