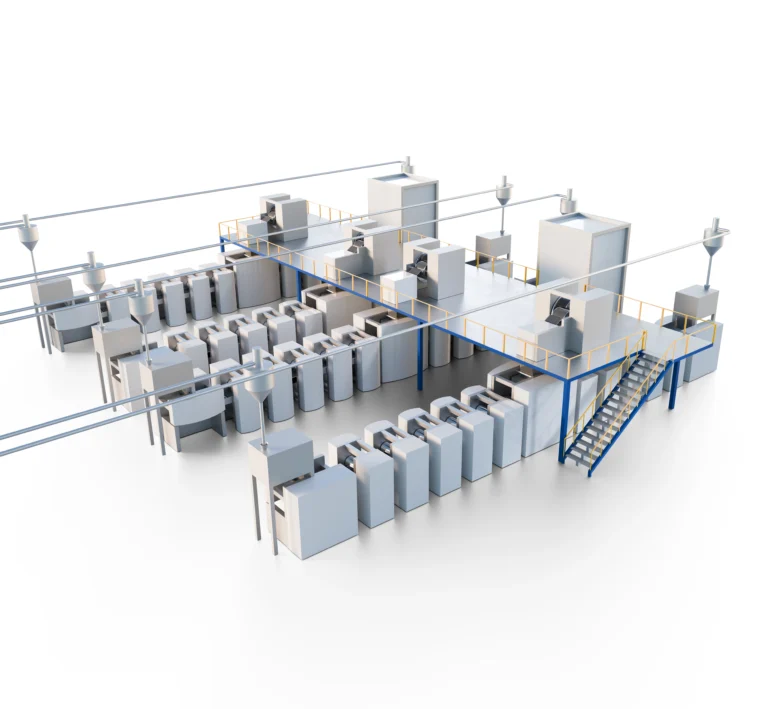

Dürr has unveiled X.Cellify DC, a new dry coating system that produces a 100% recyclable, free-standing film of battery active material before it is laminated onto collector foil. The proof-of-concept demonstration, conducted at the company’s pilot facility in Chassieu, France, confirms the process is reliable, scalable and ready for gigawatt-scale industrial trials. Initial applications will target lithium-ion batteries, with potential use in future solid-state designs.

Traditional electrode production relies on wet coating, where active materials are applied to metal foils in a solvent and then dried in energy-intensive ovens. In contrast, X.Cellify DC uses a solvent-free, dry powder mixture that is pressed into a film via the Activated Dry Electrode® process developed by LiCAP Technologies. Dürr’s system handles all key steps—from dosing and film formation to densification and final lamination on both sides of the collector foil.

By eliminating dryers and solvent recovery units, the dry coating approach can reduce production space requirements by up to 65% and cut energy consumption by as much as 70%. Because the film remains “free-standing” until the final lamination step, any material that fails to meet quality specifications can be returned to the process without loss, significantly reducing scrap rates.

A horizontal calender initially shapes the dry powder into a film, which is then compressed by additional calenders to achieve the target thickness, density and porosity. The self-supporting web guidance system transports and compresses the film prior to lamination, requiring less force than wet-coated electrodes and minimizing foil deformation. This improves downstream steps such as notching and stacking.

X.Cellify DC combines Dürr’s expertise in electrode manufacturing and system integration, Dürr Ingecal’s precision calenders, and LiCAP’s patented dry electrode technology. With a successful proof-of-concept in place, Dürr is now seeking industrial partners for gigawatt-scale pilot projects across applications including electric vehicles and stationary storage, advancing the next generation of battery production.

Source: Dürr