On September 3, 2025, Gelion plc, the UK-Australian battery technology innovator, announced the successful integration of advanced materials from the Max Planck Institute of Colloids and Interfaces (MPI) and the in-house fabrication of sulfur cathode active material at its Sydney-based ACPC facility. This achievement represents a significant technical milestone in the development of Gelion’s next-generation lithium-sulfur (Li-S) and room-temperature sodium (Na-S) battery technologies.

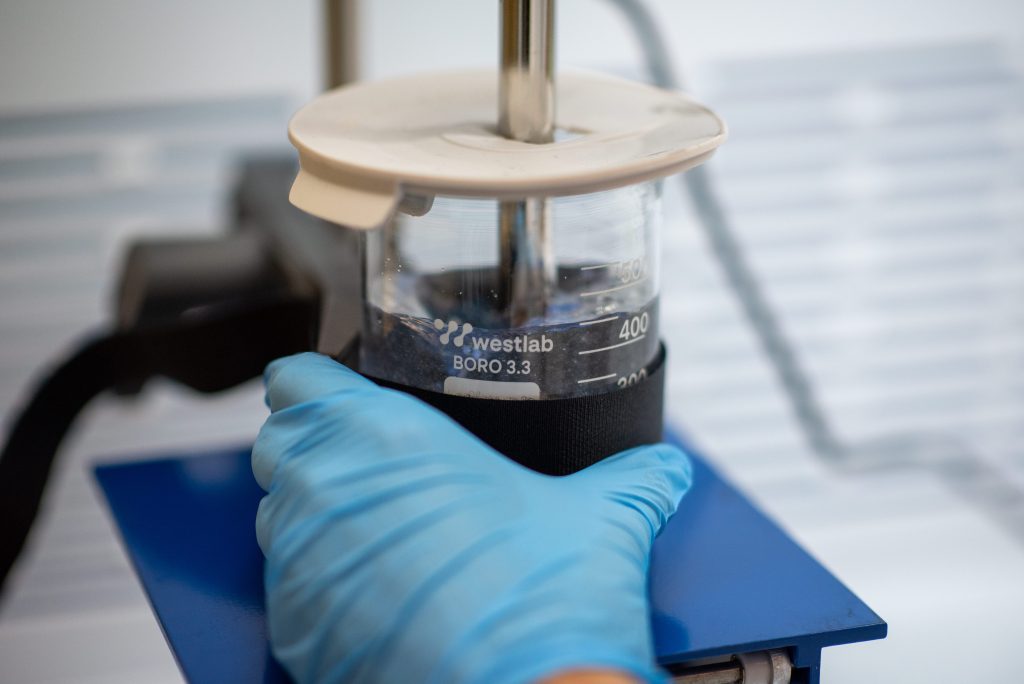

Following the strategic collaboration with MPI announced in March 2025, Gelion has completed the full transfer of MPI’s proprietary sulfur cathode active material (CAM) technology into its own development and production ecosystem. By bringing fabrication, cell prototyping and testing capabilities under one roof, the company gains end-to-end operational control and streamlines its path toward scale-up and commercialization of sulfur CAM for both Li-S and Na-S systems.

With fabrication now commissioned in Sydney, Gelion can substantially expand partner testing programs. Higher material volumes compared to those available at MPI will support multiple concurrent trials, accelerate feedback loops and enable more rapid iteration on cell design and performance optimization. This increase in throughput is expected to materially reduce technical risks and bolster the pathway to market adoption of Gelion’s high-energy, high-power, long-life sulfur-based batteries.

John Wood, Gelion’s CEO, commented on the milestone: “We’re pleased to have completed this transfer in close collaboration with MPI. Our team, including our research lead who spent significant time at MPI, has demonstrated exceptional commitment. With enhanced fabrication capacity, we are scaling up internal development and supporting ongoing external testing as we drive towards commercial deployment.”

By internalizing the sulfur CAM process and accelerating partner collaborations, Gelion aims to de-risk technology scale-up and move closer to delivering advanced battery solutions for energy storage and electric mobility applications.

Source: Gelion