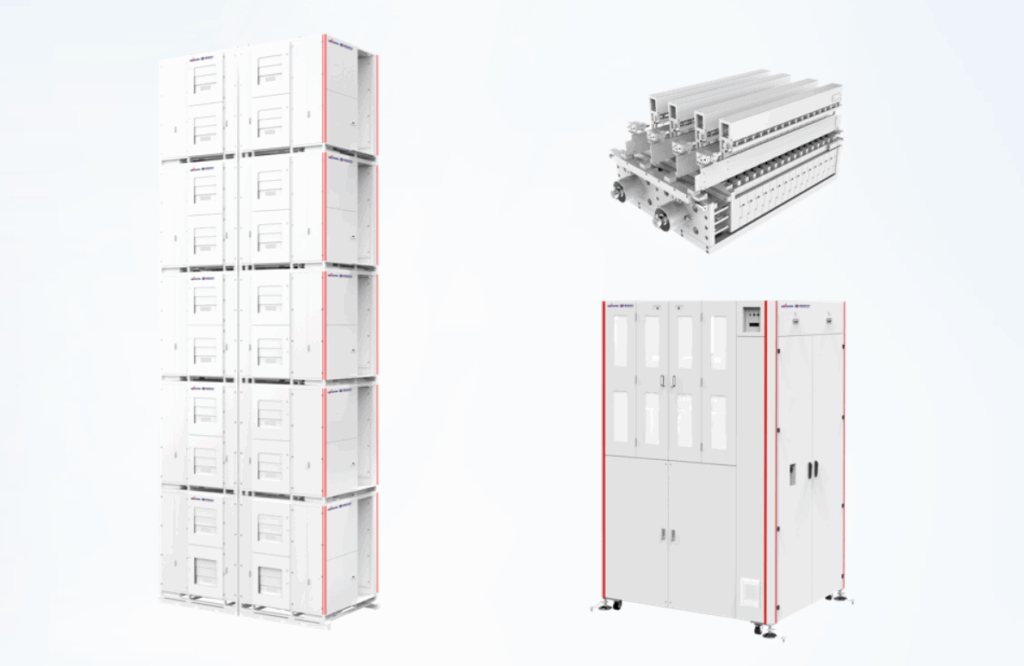

LEAD has unveiled an advanced battery formation and grading system designed to support lithium battery manufacturers in reducing energy consumption, lowering operating costs, and improving production consistency. As global demand for lithium batteries continues to rise, conventional formation and grading methods have struggled with high power draw, limited temperature accuracy, and maintenance challenges. LEAD’s new platform addresses these pain points through an integrated, energy-efficient approach.

The solution’s water-integrated thermal management delivers three core innovations. First, a hot-water-based temperature control mechanism maintains the battery cavity at 25 ± 1.5 °C, improving control accuracy by 50% and cutting high-temperature zone volume by 60%. This approach lowers overall plant energy use. Second, the unified system architecture replaces traditional split-system layouts, reducing charging energy by 6% and shrinking the installation footprint by 20%. Pre-assembled modules also accelerate on-site setup and commissioning by around 30%. Third, a “no high-temperature room” configuration trims power wiring requirements by 30%, allowing maintenance in standard ambient conditions for enhanced safety and comfort.

In parallel, LEAD’s negative-pressure cleanroom workstation improves process automation and cleanliness while minimizing overhead. By integrating tray-following technology with negative-pressure components, the design preserves injector port hygiene and cuts required cleanroom area by up to 90%, translating into millions of dollars in annual facility savings. The workstation also introduces ground-level maintenance, automated disassembly, leak detection, and clogging diagnostics, boosting replacement efficiency by 80% and supporting further production-line automation. Real-time electrolyte exhaust handling and robust sealing help form a high-quality SEI film, extending battery cycle life and overall reliability.

Performance results from LEAD’s intelligent formation and grading solution include charging efficiencies above 88% and discharge efficiencies exceeding 85%. A single production line can yield tens of millions in construction savings while delivering substantial reductions in annual operating expenses, enabling a faster return on investment. By integrating equipment design, process engineering, and plant layout into a unified “space–energy–labor” cost-control system, LEAD aims to empower manufacturers to achieve sustainable, intelligent production and strengthen their competitive position.

Source: Lead Intelligent