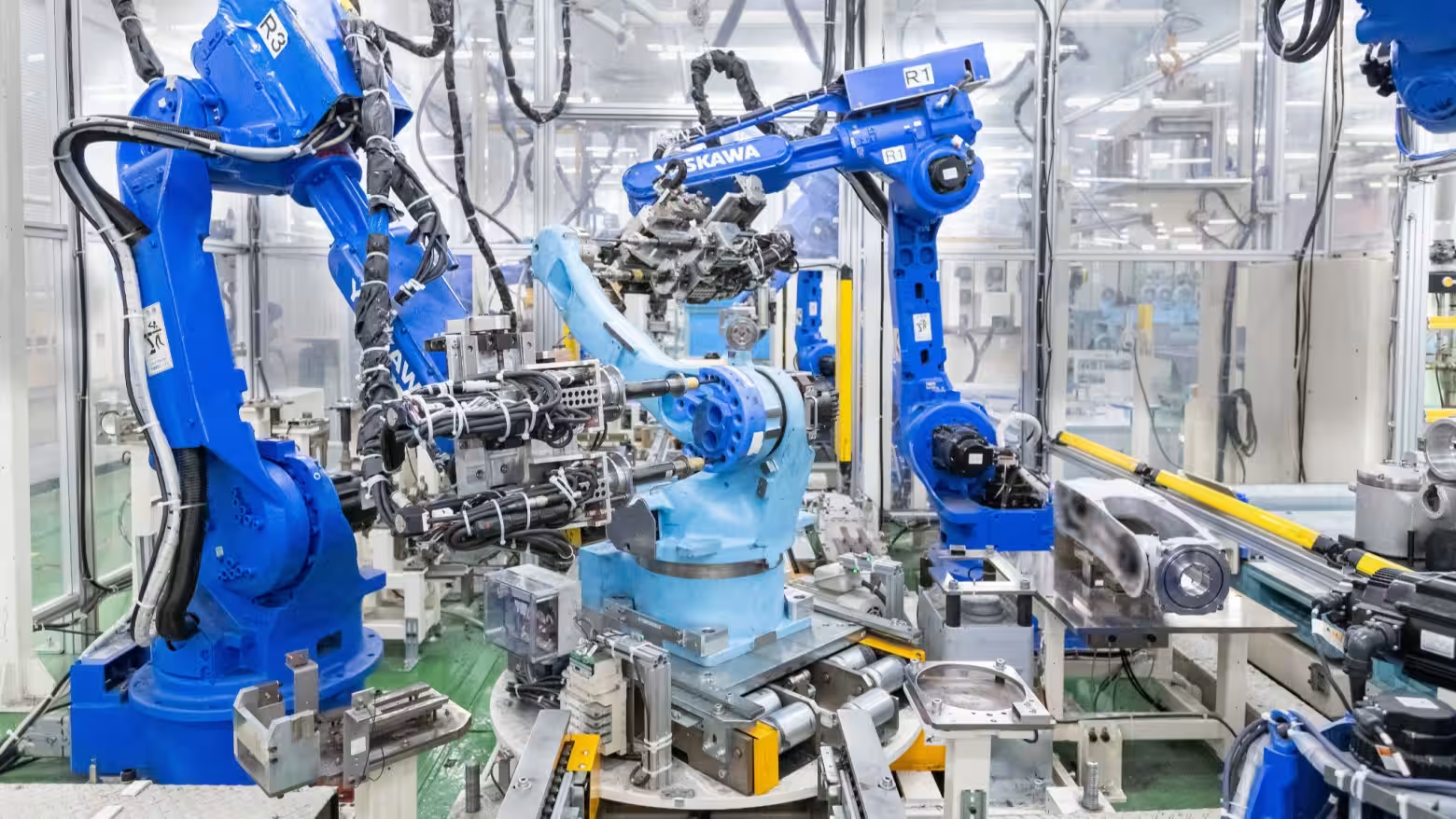

Maxell has begun test operations of its ceramic-packaged all-solid-state battery modules, designated PSB401010H, at Subaru’s Oizumi Plant in Gunma Prefecture. Installed in industrial robots and their controllers, these rechargeable power modules are being evaluated for use in Subaru’s engine and transmission production line. Test activities started in August.

Traditionally, industrial robots in automotive manufacturing rely on single-use primary batteries to maintain memory and real-time clock functions during power interruptions. Such batteries typically require replacement every one to two years, generating significant industrial waste and maintenance labor. Maxell’s all-solid-state modules are designed to operate reliably in harsh production environments and offer an estimated service life of more than ten years, potentially eliminating frequent battery changes and reducing waste disposal.

By integrating the PSB401010H modules, Subaru anticipates a decline in both battery replacement tasks and the volume of used-battery waste at the Oizumi Plant. The modules’ solid-electrolyte design enhances safety and thermal stability compared with conventional lithium-ion cells, while maintaining high output and capacity characteristics. These attributes make them suitable for applications where long-term reliability and resistance to extreme conditions are critical.

Maxell plans to use the Subaru trial as a stepping stone toward broader adoption across other manufacturing facilities. Drawing on its Analog Core Technologies, the company is focusing on four core performance objectives—long cycle life, high heat resistance, high power output, and substantial capacity—to expand the range of applications for its all-solid-state solutions. These efforts aim to address industry demand for safer, more durable energy storage in sectors where traditional batteries may fall short.

Continued development and testing will determine how quickly Maxell can scale production and integrate its modules into additional industrial contexts. If successful, the initiative could set a new standard for backup power systems in automated manufacturing lines, offering both environmental and operational benefits.

Source: Business Wire