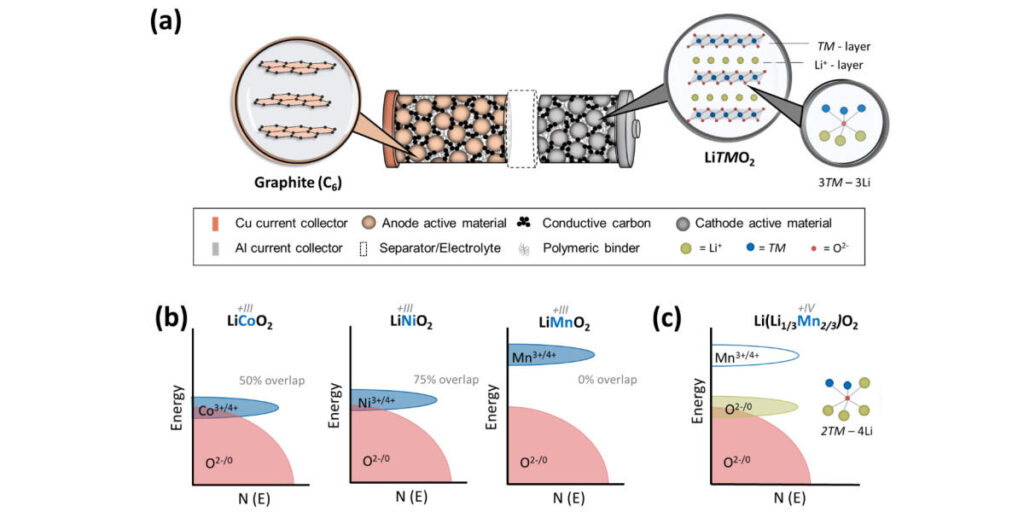

A multidisciplinary team led by the MEET Battery Research Center at the University of Münster has proposed a structured framework for advancing lithium/manganese-rich layered oxide (LMR) cathodes in lithium-ion batteries. Although LMR materials promise high energy density at relatively low cost, their stability falls short of more established chemistries such as lithium-nickel-manganese-cobalt oxide (NMC). The authors’ review, published in Advanced Science, addresses the complexity of LMR research by establishing standardized metrics for compositional design and performance evaluation.

Researchers first cataloged a wide array of LMR compositions and assessed each variant’s electrochemical performance alongside material- and cell-level costs. By comparing specific energy, energy density and overall cost with those of commercial cathode chemistries paired with graphite-based anodes, the team identified key trade-offs that can guide future material selection. “This cost-performance benchmarking is a crucial step toward commercial viability,” said Dr. Anindityo Arifiadi of MEET.

Beyond overall composition, the review examines how crystal lattice parameters, particle microstructure, surface coatings and electrolyte formulations influence cycle life, rate capability and thermal stability. Dr. Johannes Kasnatscheew, head of MEET’s Materials Division, notes that consistent testing protocols—such as comparing cells at equivalent states of charge rather than fixed voltage cut-offs—will enable fairer, more reproducible comparisons across studies.

The article reflects contributions from both academic and industry partners, including experts from Stanford University, AGH University of Science and Technology (Poland), LG Energy Solution and the Helmholtz Institute Münster of Forschungszentrum Jülich. This international collaboration underscores the collective effort required to optimize LMR cathodes and accelerate their path to market.

By laying out systematic guidelines for composition, characterization and cost analysis, the review aims to streamline R&D workflows and foster more direct comparisons among emerging LMR materials. Such an approach could expedite development timelines and support the commercialization of next-generation, high-energy lithium-ion batteries.

Source: Advanced Science