Volkswagen Group has reached a global milestone by producing five million electric drive units, underscoring the strength of its cross-brand technology and production network. The total includes output from the Győr, Kassel, Tianjin and Zuffenhausen plants, and highlights the systematic expansion of e-mobility across multiple regions. In 2025, the Kassel facility boosted its electric drive production by about 24% year-on-year, exceeding 850,000 units.

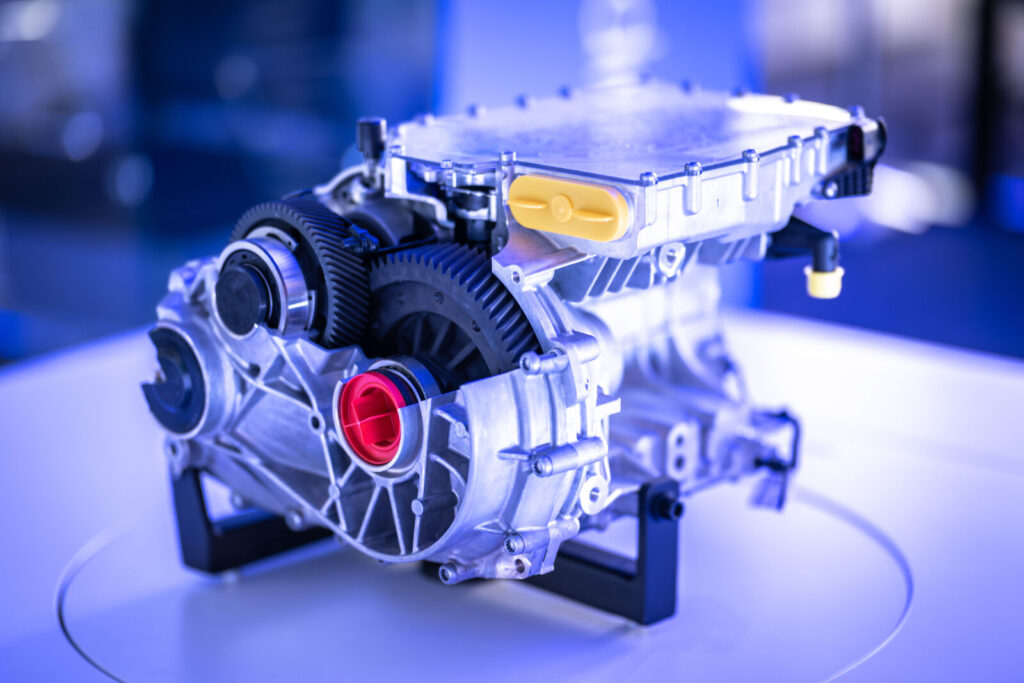

The APP550 drive system is currently the Group’s most widely used electric drive. Manufactured in Kassel, it has surpassed one million units produced. Despite having the same dimensions as its predecessor, the APP550 delivers up to 240 kW of power and 560 Nm of torque, while reducing energy consumption by around 20% and increasing torque by approximately 75% and power by about 40%. Its combined oil-and-water cooling system enhances thermal management without requiring an additional pump. The APP550 is featured in Volkswagen’s ID. models, as well as the Škoda Enyaq and CUPRA Tavascan.

Looking ahead, Volkswagen Group Components has developed an in-house pulse inverter to support the next generation of electric drives within the Electric Urban Car Family. This inverter is expected to accelerate development timelines, lower costs and increase manufacturing autonomy. In addition, the Group’s new APP290 electric motor, which uses silicon carbide semiconductors and 400V technology, will be available in output levels from 85 kW to 166 kW. This motor aims to improve range and everyday driving performance for compact electric cars such as the ID. Polo, Škoda Epiq and CUPRA Raval.

Volkswagen Group’s integrated development network oversees every stage of electric drive production—from engineering and industrialization to power electronics and logistics—ensuring key technologies are brought efficiently into series production.

Source: Volkswagen Group press release