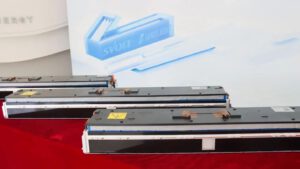

8inks’ core technology is a multi-layer coating process for battery electrodes that applies multiple thin layers of active materials during electrode production. This process, adapted from industrial sectors like paper and photographic production, enables higher energy density, enhanced cell performance, and significant cost reductions. It supports various electrode chemistries including silicon anodes, LFP cathodes, and solid electrolytes. Benefits include a 30% reduction in capital and operating costs, production speeds more than double, and a 75% reduction in factory floor space requirements.

The technology is designed for a wide range of battery applications, from small coin cells to large-format packs used in electric vehicles and industrial energy storage. The process supports flexible manufacturing for various battery sizes and chemistries, targeting markets such as electric vehicles, grid-scale energy storage, and consumer electronics.

In 2023, 8inks scaled its multi-layer battery electrode coating technology to industrial levels. It established collaborations with automotive manufacturers to pilot its technology in larger-format cells for electric vehicles and integrated its production solutions into grid energy storage platforms, supporting renewable energy initiatives.

8inks closed a pre-seed funding round raising nearly €3M, supported by investors including Founderful, Übermorgen Ventures, Angel Invest, another.vc, and the ETH Foundation. They also received support from Innosuisse, Switzerland Innovation, and the Gebert Rüf Foundation to facilitate the company’s transition to industrial-scale solutions.