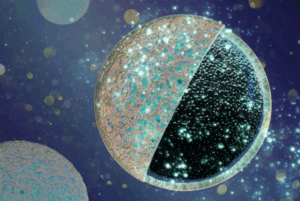

GCK Battery’s core technology includes 48V lithium-ion batteries (24V in development), modular systems scalable from 3.6V to 1000V, and custom designs. Its proprietary immersed battery technology co-developed with Motul submerges modules in dielectric fluid for ultra-fast charging under 10 minutes, enhanced thermal stability, and reduced thermal runaway risk. An in-house Battery Management System optimizes performance, extends cycle life, and ensures safety. Manufacturing occurs in a 2,500 m² automated facility in Lempdes with welding systems and an SMT line, supporting high-volume production (140,000 units annually) and prototyping.

Products include standard 48V lithium-ion batteries, 24V models in development, modular systems built from scalable subunits, and fully custom battery packs ranging from lightweight (under 500g) to heavy-duty (>4 tonnes). The portfolio features immersed battery modules for ultra-fast charging, coupled with a proprietary BMS for optimized cell performance.

In 2024, GCK supplied a 48V immersed battery system to the APH-01 T3-U hybrid vehicle for the Africa Eco Race. It collaborated on the e-Blast H2 rally-raid vehicle integrating batteries with hydrogen fuel cells and retrofitted waste collection trucks with zero-emission electric systems. In 2022, it inaugurated an expanded facility for heavy-vehicle battery production and fast-charging R&D.

The company has raised $14.4M to date. Key investors include AMINVEST (led by Amaury Mulliez) in 2023 and Shift4Good in 2024, with a technology partnership from Motul. Additional support is provided by Crédit Agricole Centre France and Banque Populaire Aura.