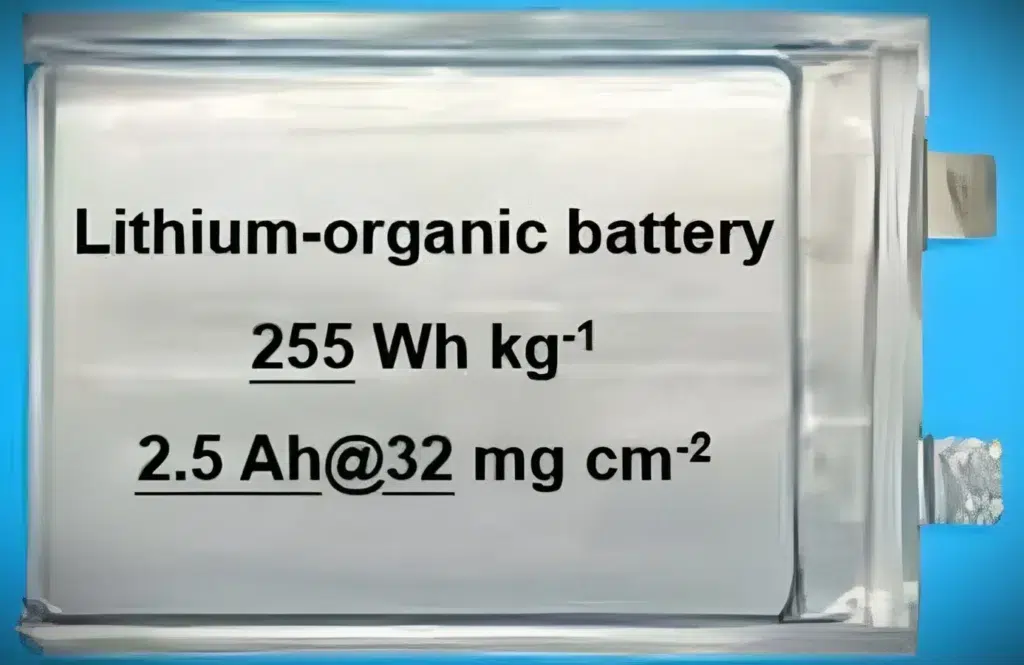

Chinese researchers have demonstrated a practical organic lithium battery prototype that delivers high energy density and operates across a broad temperature range, according to a February 18 publication in Nature. The team, led by Professors Xun Yinhua of Tianjin University and Huang Fei of South China University of Technology, employed an n-type conducting polymer called poly(benzodifurandione) (PBFDO) as the cathode material. This polymer supports rapid lithium-ion transport, high electronic conductivity, and limited solubility. As a result, pouch cells achieved energy densities above 250 Wh/kg and functioned reliably from –70 °C to 80 °C. Researchers produced 2.5 Ah pouch cells featuring an areal capacity of roughly 42 mAh/cm² and ultrahigh mass loading of up to 206 mg/cm². These performance metrics place the prototype within the range of conventional lithium-ion chemistries, while introducing an organic-based pathway. Unlike typical cathodes that depend on cobalt or nickel, organic polymers draw on abundant molecular precursors and offer structural flexibility. In mechanical tests, the organic cells maintained integrity under bending, stretching, and compression. They also passed stringent safety evaluations—including needle puncture—without deformation or unexpected energy release. The polymer’s flexibility could extend applications to flexible electronics and wearable energy storage.

Globally, research groups in Japan, Korea, and Europe have explored organic electrodes as sustainable alternatives to metal-based chemistries, often focusing on material-level enhancements such as dissolution suppression and improved conductivity. However, few have delivered practical pouch cells with both high energy density and mechanical robustness. This Nature-reported work is notable for demonstrating a fully functional prototype whose performance and temperature tolerance closely rival those of conventional systems.

While still at the prototype stage, the organic lithium battery aligns with broader industry efforts to diversify battery chemistries by 2026–2027, including solid-state and sodium-ion approaches. The technology opens a materials pathway that may reduce reliance on critical metals and broaden operability in extreme environments, though full automotive scaling and vehicle qualification testing remain future steps.

Source: CarNewsChina