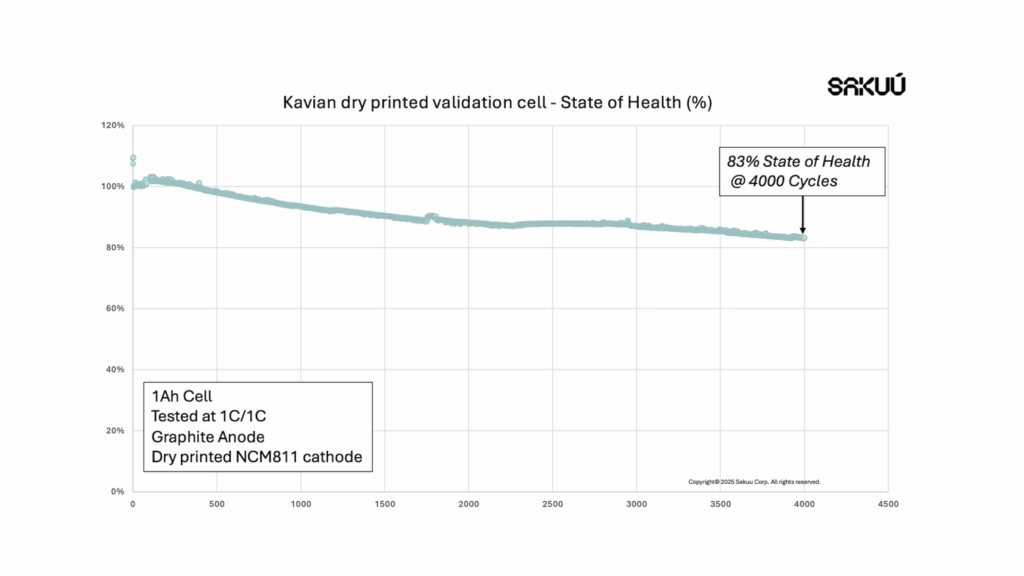

Sakuu has published independent test results showing that a lithium-ion cell featuring a fully dry-processed cathode retains 83 percent of its initial capacity after 4,000 cycles. These results, achieved using the company’s Kavian additive manufacturing platform, mark a significant advance for dry-printed electrodes and compare favorably to typical nickel-cobalt-manganese (NCM) cells, which generally exceed 2,000 cycles at 80 percent state of health for electric-vehicle applications.

The validation cell was produced without the introduction of new materials or chemistry optimizations. It is a 1 Ah cell with a graphite anode and an NCM811 cathode printed entirely through Kavian’s dry-process technology. Cycle testing was conducted at a 1C charge and 1C discharge rate, confirming the platform’s ability to deliver reliable, long-life performance using existing electrode formulations.

“We’re so proud of the performance of Kavian-manufactured battery electrodes,” said Robert Bagheri, Sakuu founder, CEO, and executive chairman. “Our extensive testing confirms that Kavian’s dry manufacturing process can be reliably trusted to deliver a product that will meet or exceed the capabilities of current wet processes. This again dispels any doubts as to the suitability of using a dry process for printing lithium-ion (Li-ion) battery electrodes. This myth-busting achievement is a testament to our materials engineering expertise, as customers tell us other additive manufacturers experimenting with dry processes struggle to achieve satisfactory results across the entire printed electrode — particularly the cathode.”

The Kavian platform currently supports a broad range of electrode chemistries, including NCA, NCM, LFP, LTO, graphite and silicon-graphite. Its flexibility also extends to emerging formulations such as aluminum-ion, sodium-ion and solid-state designs. In addition to battery electrodes, Kavian can dry print supercapacitor electrodes to meet the fast-power demands of high-performance data centers.

Compared with conventional wet-coat electrode production, the dry process eliminates toxic solvents and water, reduces manufacturing floor space by 60 percent, cuts utility costs by 30 percent and lowers CO2 emissions by 55 percent. It also offers roughly 20 percent savings in capital equipment costs, enabling more sustainable, regionalized battery and supercapacitor manufacturing.

Sakuu has begun fulfilling initial orders for Kavian and has delivered hundreds of meters of dry-printed electrode material to early customers. For more information, the company will exhibit at the Advanced Automotive Battery Conference in Las Vegas from December 8 to 11.

Source: Sakuu News